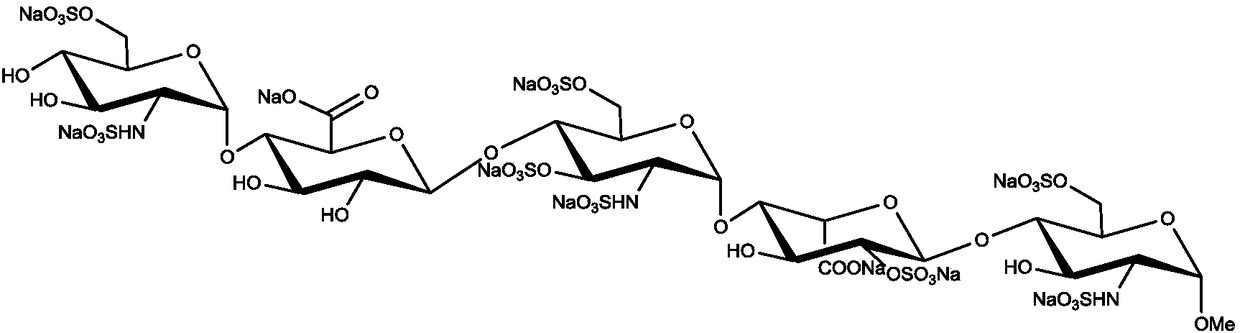

Preparation method of fondaparin sodium intermediate

A technology for fondaparinux sodium and preparation steps, which is applied in the field of medicine, and can solve the problems of complicated purification process, low purity of intermediates, cumbersome process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

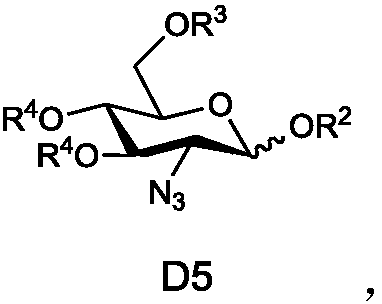

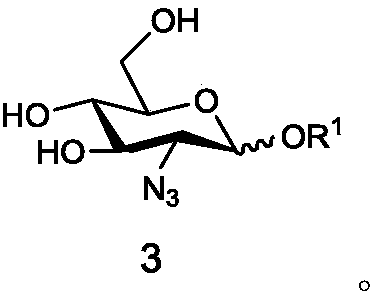

Method used

Image

Examples

Embodiment 1

[0082]

[0083] Put 250L of anhydrous methanol into the reaction kettle, lower the temperature to 15-20°C, add 19.4kg of concentrated sulfuric acid dropwise, fully stir for 15min after the dropwise completion, then add 25kg of acetylglucosamine (a), heat and reflux for reaction, and TLC detects that the reaction is complete ( Rf=0.3, dichloromethane:methanol=3:1), lower the temperature and add 31.24kg of potassium carbonate to adjust the pH to alkaline, filter, and wash the filter cake with 50L of anhydrous methanol to obtain a methanol solution of compound b.

Embodiment 2

[0085]

[0086] Add the methanol solution of compound b to the reaction kettle, then add 180g of anhydrous copper sulfate and 18.7kg of potassium carbonate, cool to about 0°C, and add 28.4kg of ImSO 2 N 3 After adding hydrochloride, heat up to 25-30°C to react, TLC detects that the reaction is complete (Rf=0.6, dichloromethane:methanol=3:1), filter, and wash the filter cake with 50L methanol, and concentrate the filtrate under reduced pressure Methanol was removed to obtain the crude product of compound c.

Embodiment 3

[0088]

[0089] Add 300L of glacial acetic acid to the crude compound c to dissolve, then add 51.9kg of acetic anhydride, rise to 30-40°C to react, and TLC monitors that the reaction is complete (petroleum ether: ethyl acetate = 3:1, Rf = 0.4). Add 20L of anhydrous methanol to quench the reaction, then add 500L of ethyl acetate to dilute, successively wash with 500L×2 purified water, 500L×2 saturated sodium bicarbonate solution and 500L saturated brine, dry over anhydrous sodium sulfate, filter, and concentrate to obtain Compound d crude. Add 30L of anhydrous methanol to the crude product, heat to reflux to dissolve, then cool down to crystallize, and filter to obtain 27.9kg of compound d with a purity of 98.5% and a yield of 71.7%.

[0090] Add 279L of methanol, 0.9kg of sodium methoxide and compound d into the reactor, react at 25-30°C for 1-2 hours, TLC detects that the reaction is complete (petroleum ether: ethyl acetate = 3:1, the product is at the origin, the raw mate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com