Metal alloy-metal oxide double magnetic shell-core structure nanocrystal and preparation method and application thereof

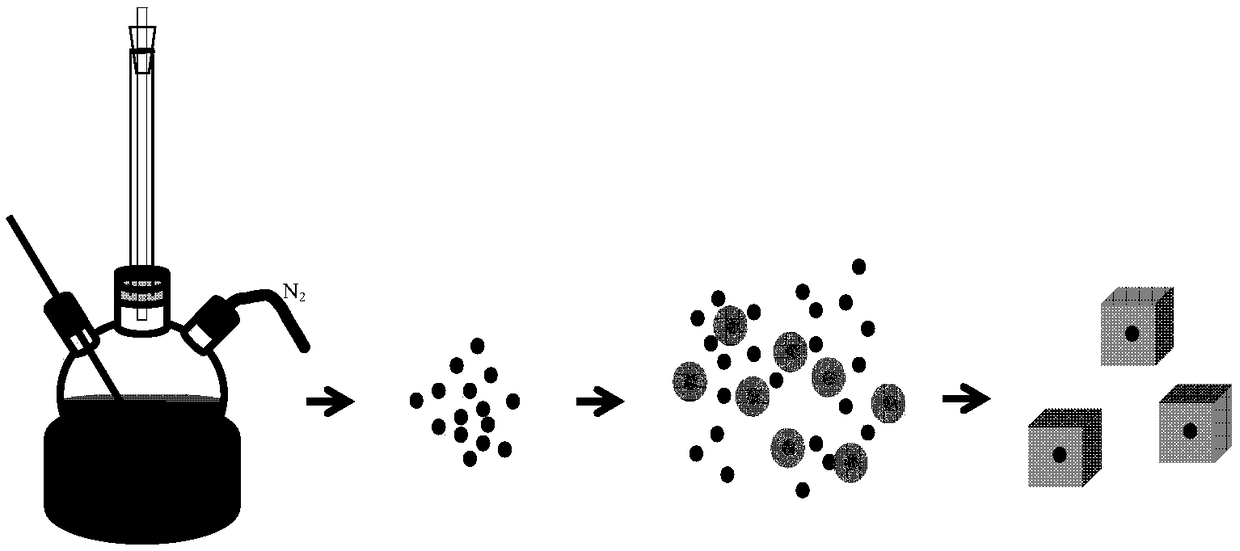

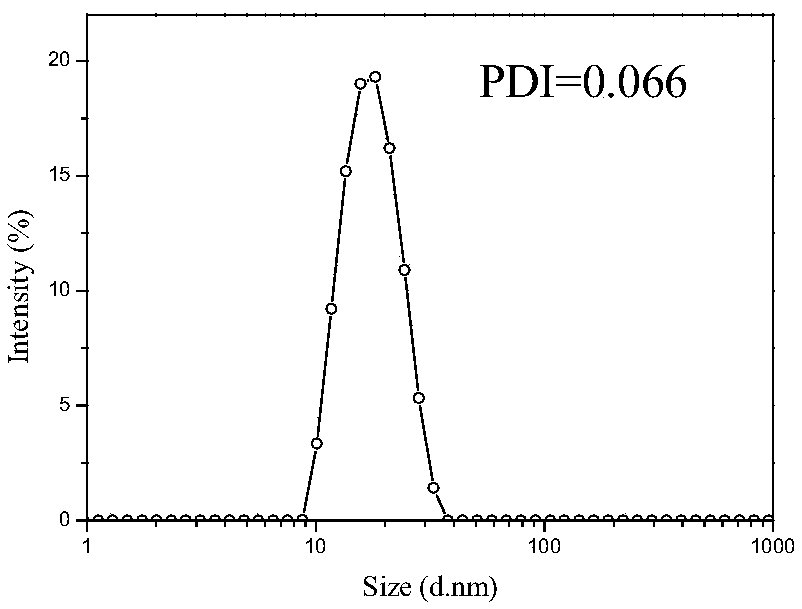

A shell-core structure and metal alloy technology, applied in the field of nanomaterials, can solve the problems of cumbersome operation process, waste of reagents and consumables, etc., and achieve the effects of simple process, expansion of magnetic properties, and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] Embodiment 1, FePt@Fe 3 o 4 Preparation of Core-Shell Nanocrystals

[0063] Add 0.5mmol of platinum acetylacetonate, 1.5mmol of 1,2-hexadecanediol and 20mL of 1-octadecene into a 150mL three-necked flask, stir and mix evenly with a magnetic force at 1600rpm / min, vacuumize at 40°C for 30min, blow nitrogen, and add 1.6 mL oleic acid, 1.7 mL oleylamine, and 3 mmol iron acetylacetonate (platinum acetylacetonate: 1,2-hexadecanediol: iron acetylacetonate: oleic acid: oleylamine: 1-octadecene in a ratio of 1:3:6 :10:10:62.5), evacuate at 80°C for 30min, blow nitrogen, raise the temperature to 300°C, and reflux for 30min. Remove the heat source, cool to room temperature, then add an appropriate amount of ethanol, centrifuge at 6000r / min for 10min, take the precipitate, then add an appropriate amount of cyclohexane to dissolve the product, centrifuge again at 6000r / min for 10min, take the upper layer, and repeat ethanol The process of precipitation / cyclohexane dispersion was ...

Embodiment 2

[0066] Embodiment 2, FePt@Fe 3 o 4 Preparation of Core-Shell Nanocrystals

[0067] Add 0.1mmol of platinum acetylacetonate, 0.3mmol of 1,2-hexadecanediol and 20mL of 1-octadecene into a 150mL three-necked flask, stir and mix evenly with a magnetic force at 1600rpm / min, vacuumize at 40°C for 30min, blow nitrogen, and add 1.6 mL oleic acid, 1.7 mL oleylamine, and 2 mmol iron acetylacetonate (platinum acetylacetonate: 1,2-hexadecanediol: iron acetylacetonate: oleic acid: oleylamine: 1-octadecene in a ratio of 1:3:20 :50:50:312.5), vacuumize at 80°C for 30min, blow nitrogen, raise the temperature to 300°C, and reflux for 30min. Remove the heat source, cool to room temperature, then add an appropriate amount of ethanol, centrifuge at 6000r / min for 10min, take the precipitate, then add an appropriate amount of cyclohexane to dissolve the product, centrifuge again at 6000r / min for 10min, take the upper layer, and repeat ethanol The process of precipitation / cyclohexane dispersion w...

Embodiment 3

[0070] Embodiment 3, FePt@Fe 3 o 4 Preparation of Core-Shell Nanocrystals

[0071] Add 0.3mmol of platinum acetylacetonate, 0.9mmol of 1,2-hexadecanediol and 20mL of 1-hexadecene into a 150mL three-necked flask, stir and mix evenly with a magnetic force at 1600rpm / min, vacuumize at 40°C for 30min, blow nitrogen, and add 1.6 mL oleic acid, 1.7 mL oleylamine, and 3 mmol iron acetylacetonate (platinum acetylacetonate: 1,2-hexadecanediol: iron acetylacetonate: oleic acid: oleylamine: 1-octadecene in a ratio of 1:3:10 :16.7:16.7:104.2), vacuumize at 80°C for 30min, pass nitrogen gas, heat up to 300°C, and reflux for 30min. Remove the heat source, cool to room temperature, then add an appropriate amount of ethanol, centrifuge at 6000r / min for 10min, take the precipitate, then add an appropriate amount of cyclohexane to dissolve the product, centrifuge again at 6000r / min for 10min, take the upper layer, and repeat ethanol The process of precipitation / cyclohexane dispersion was per...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com