Solid-phase synthesis method of nano magnesium aluminosilicate for waterborne rheological auxiliary agent

A rheological additive, magnesium aluminum silicate technology, applied in the direction of aluminum silicate, nanotechnology for materials and surface science, silicate, etc., can solve the problems of high production safety risks, complex production processes, and large water consumption Resources and other issues, to achieve the effect of high viscosity, high purity, water saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

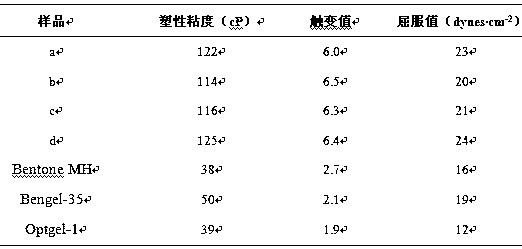

Examples

Embodiment 1

[0021] A kind of nano-magnesium aluminum silicate for water-based rheological additives is prepared according to the following steps from the following raw material components in parts by mass:

[0022] (1) First, 5 parts of Ce(NO 3 ) 3 Add to 500 parts of pure water and stir thoroughly, then add 100 parts of water glass (modulus 3.0), then slowly drop in 10 parts of sodium hydroxide solution with a mass fraction of 1%, and control the dropping time to 10 minutes;

[0023] (2) Next, add 1 part of ferric sulfate and 100 parts of aluminum sulfate to 500 parts of pure water and stir thoroughly, then slowly drop in 10 parts of sodium hydroxide solution with a mass fraction of 1%, and control the dropping time to 10 minutes;

[0024] (3) Next, mix the solution of step (1) and step (2) and heat up to 30°C, then add 5 parts of magnesium sulfate and 0.5 parts of zinc nitrate, and continue to keep stirring for 10 minutes; then roast the reaction system at 150°C 1h, finally lowered to...

Embodiment 2

[0026] A kind of nano-magnesium aluminum silicate for water-based rheological additives is prepared according to the following steps from the following raw material components in parts by mass:

[0027] (1) First, 5 copies of Ce 2 (SO 4 ) 3 and 5 Dy(NO 3 ) 3 Add to 500 parts of pure water and stir thoroughly, then add 200 parts of water glass (modulus 3.3), then slowly drop in 30 parts of sodium hydroxide solution with a mass fraction of 5%, and control the dropping time to 30 minutes;

[0028] (2) Next, add 2 parts of ferric nitrate, 3 parts of ferric ammonium sulfate, 100 parts of aluminum nitrate and 100 parts of aluminum sulfate into 500 parts of pure water and stir thoroughly, then slowly drop in 30 parts of 5% hydroxide Sodium solution, control the dropping time to 30min;

[0029](3) Next, mix the solution of step (1) and step (2) and heat up to 50°C, then add 5 parts of magnesium sulfate, 5 parts of magnesium nitrate, 0.5 parts of zinc sulfate, and 1 part of zinc n...

Embodiment 3

[0031] A kind of nano-magnesium aluminum silicate for water-based rheological additives is prepared according to the following steps from the following raw material components in parts by mass:

[0032] (1) First, 3 parts of Ce(NO 3 ) 3 , 3 copies of Dy 2 (SO 4 ) 3 , 3 parts of Sr(NO 3 ) 2 Add to 500 parts of pure water and stir thoroughly, then add 150 parts of water glass (modulus 3.1), then slowly drop in 15 parts of sodium hydroxide solution with a mass fraction of 2%, and control the dropping time to 20 minutes;

[0033] (2) Next, add 1 part of ferric sulfate, 1 part of ferric nitrate, 1 part of ferric ammonium sulfate, 60 parts of aluminum sulfate and 70 parts of aluminum nitrate into 500 parts of pure water and stir thoroughly, then slowly drop in 20 parts of 3% sodium hydroxide solution, the control dripping time is 15min;

[0034] (3) Next, mix the solution of step (1) and step (2) and heat up to 40°C, then add 3 parts of magnesium sulfate, 3 parts of magnesium...

PUM

| Property | Measurement | Unit |

|---|---|---|

| modulus | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com