Method and device for measuring boiler hearth ash fouling coefficient online

A coefficient and fouling technology, which is applied to the indication of boiler working conditions, etc., can solve the problems of large model error, large fluctuation of input parameters, and long measurement lag time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

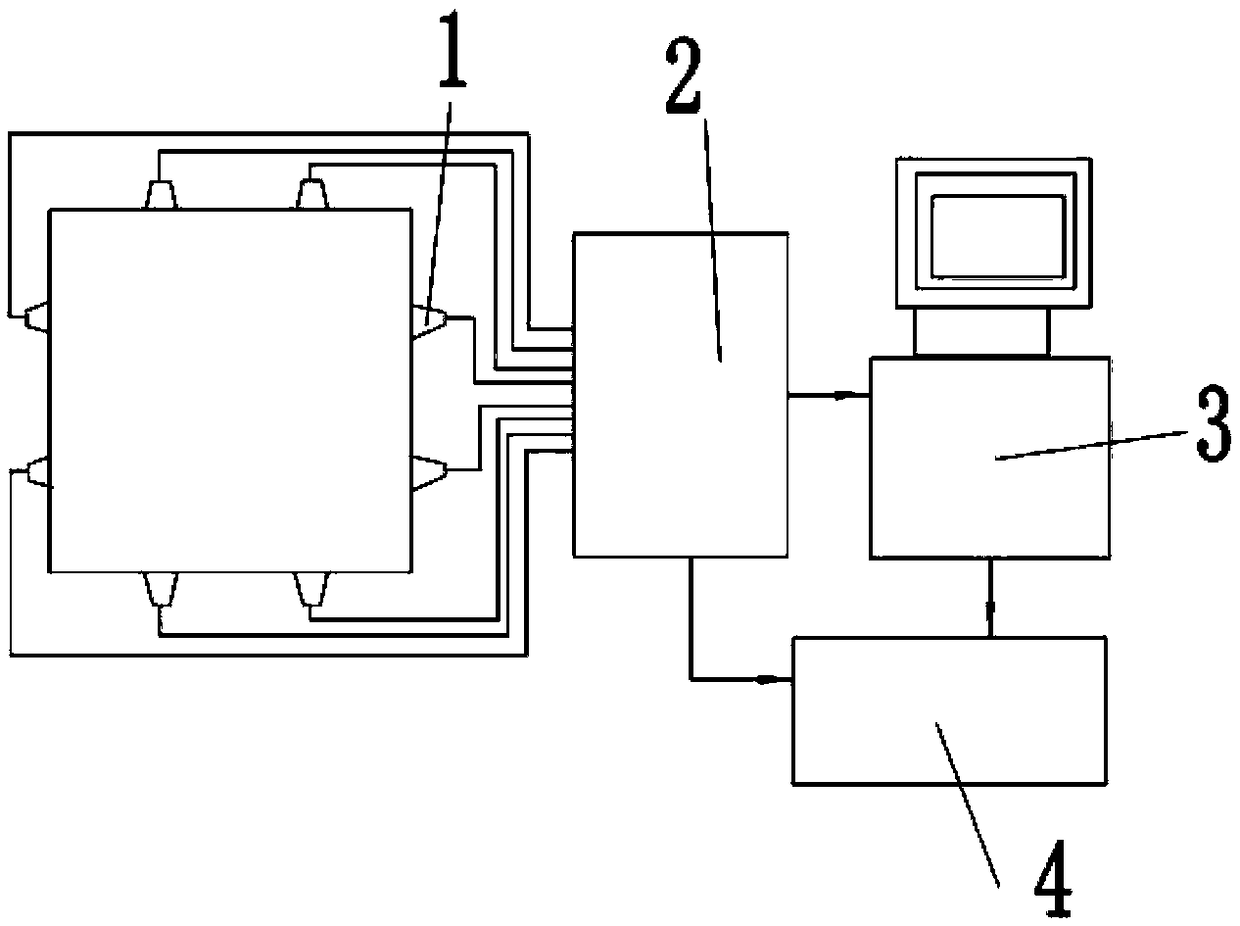

[0077] Such as Figure 1-5 As shown, a method for online measurement of boiler furnace soot coefficient, including the following steps:

[0078] (1) Under the reference operating state of the boiler, the three-variable test of multiple operating conditions is carried out to determine the influence of furnace load, pulverized coal burner commissioning state, burner swing angle and flame radiation temperature, and obtain the boiler reference state. Specific flame radiation temperature variation law;

[0079] (2) Under the actual operating state of the boiler, measure the operating parameters such as furnace load, pulverized coal burner commissioning state, burner swing angle, etc., and use the specific flame radiation temperature variation law under the reference state to determine the specific flame under the actual operating state radiation temperature;

[0080] (3) Measure the flue gas temperature of the furnace cross-section below the folding flame angle, and determine the...

Embodiment 2

[0094] A method for on-line measurement of boiler furnace dust pollution coefficient, specifically comprising the following steps:

[0095] 1) The test of the reference operating state of the boiler in the step (1), including changing the boiler load, the commissioning state of the pulverized coal burner and the swing angle of the burner while burning the designed coal type, maintaining the steam and water supply parameters within the design range Experiments with different working conditions are carried out to determine the influence of these variables on the flame radiation temperature;

[0096] Boiler load, pulverized coal burner commissioning state, burner swing angle, etc. are taken as independent variables, and the feedwater flow at the outlet of the economizer is used as the boiler load, and the specific boiler load τ is expressed as

[0097]

[0098] Among them, D is the feedwater flow rate at the outlet of the economizer, D e is the feedwater flow rate at the outl...

Embodiment 3

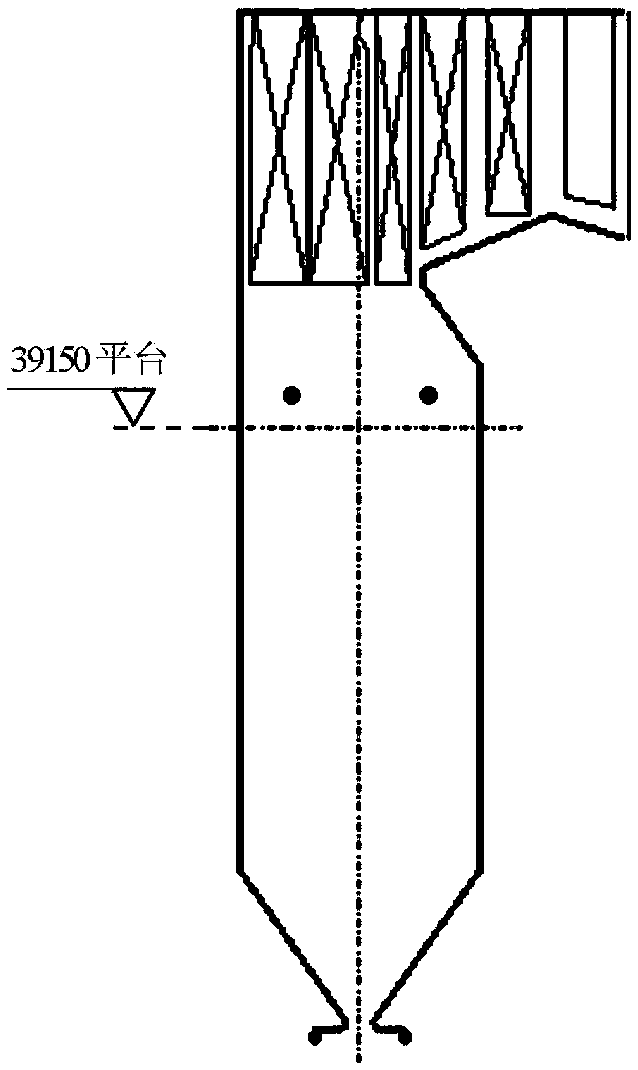

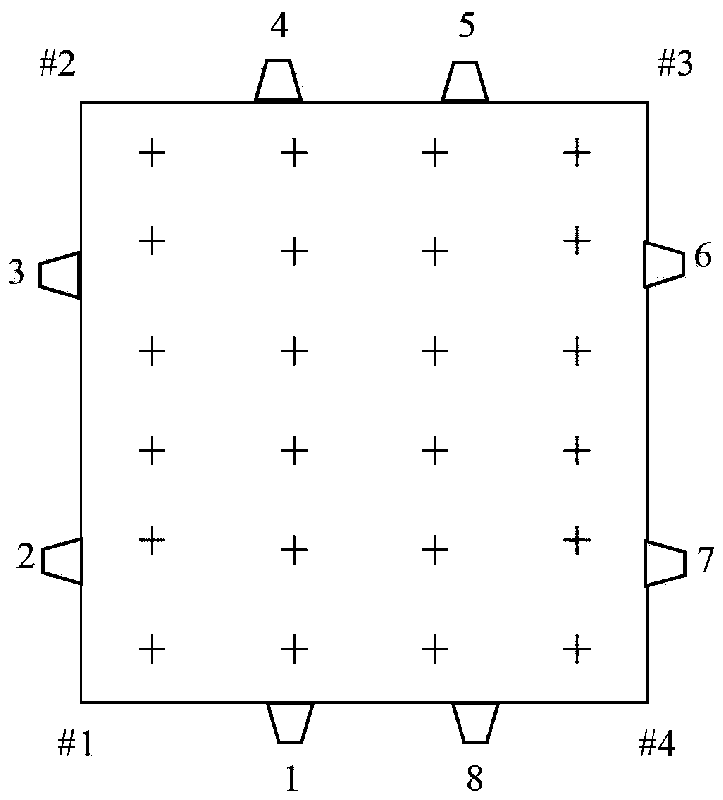

[0135] Furnace soot coefficient measurement application is carried out on a 300MW boiler, which is a subcritical, intermediate reheating, single furnace Π-shaped layout, four-corner tangential combustion, natural circulation drum boiler, and a medium-speed coal pulverizer is adopted Pressure direct blowing pulverization system, equipped with five MP212B roller disc coal mills, each pulverizer supplies pulverized coal to four pulverized coal nozzles on the same floor, from bottom to top, the pulverized coal nozzles are A, B, C, Layers D and E, the nozzle height is h in formula (5) i (i=1~5) are 8.31m, 9.91m, 11.51m, 13.11m, 14.71m respectively, the furnace height is h in formula (4) H is 49.41m, and the heating area of the water wall in formula (7) and formula (13) is F l =2758m 2 , the boiler is installed and put into operation with a furnace acoustic wave temperature measurement system, figure 1 It is the furnace acoustic wave temperature measurement system, figure 2 I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com