Novel poly(D,L-lactide-co-glycolide)-polyethylene glycol hydrogel and preparation method thereof

A polyglycolide and polyethylene glycol technology, applied in the field of materials, can solve the problems of few reports and difficult to control hydrogel degradation performance, and achieve high reaction selectivity, good biocompatibility, and reaction conditions. mild effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A novel polyethylene lactide-polyethylene glycol hydrogel, said hydrogel is composed of four-arm polyethylene lactide-polyethylene glycol-azide copolymer and four-arm alkynyl through azide -Click chemistry reaction between alkyne groups.

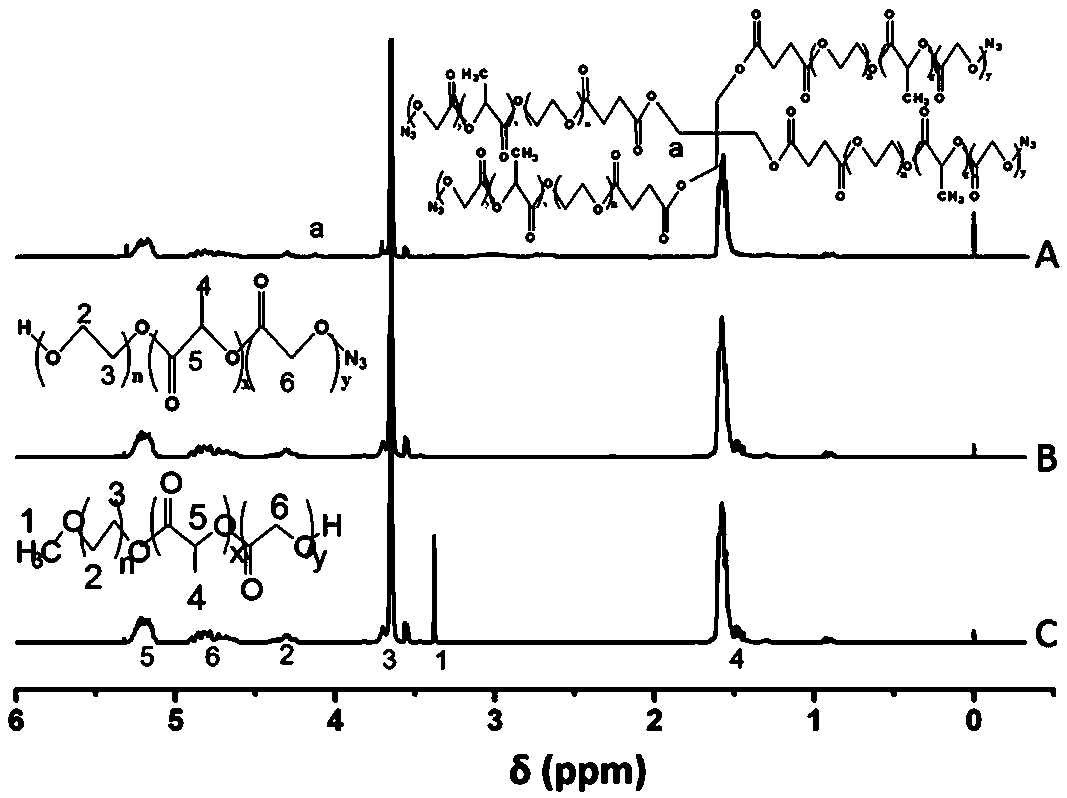

[0031] The structural formula of the four-arm polyethylene lactide-polyethylene glycol-azide copolymer is:

[0032]

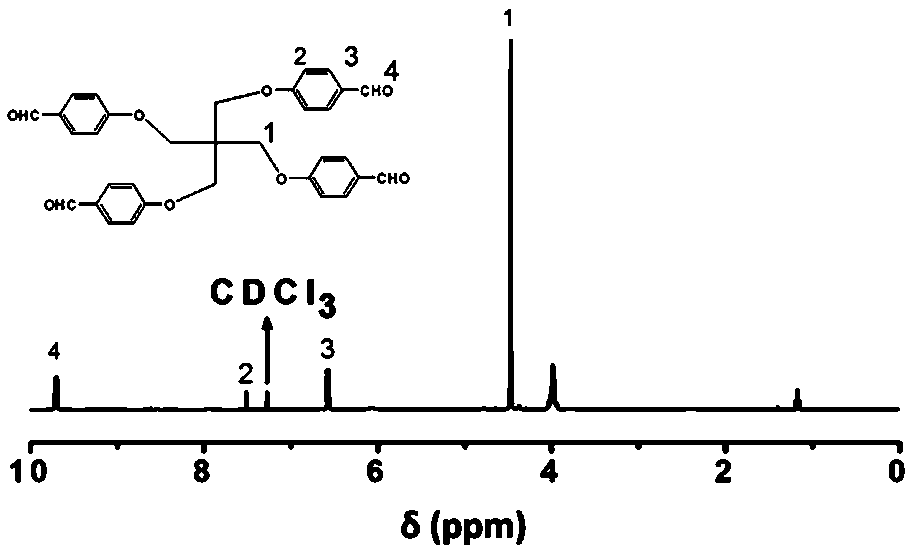

[0033] The structural formula of the four-arm alkynyl small molecule is:

[0034]

[0035] Its specific reaction formula is:

[0036]

[0037] The preparation method of the novel polyethylene lactide-polyethylene glycol hydrogel is prepared by the following steps: 1) mixing four-arm polyethylene lactide-polyethylene glycol-azide copolymer with water to obtain Four-arm polyethylene lactide-polyethylene glycol-azide copolymer aqueous solution; four-arm alkynyl is mixed with water to obtain a four-arm alkynyl aqueous solution; the four-arm polyethylene lactide-polyethylene glycol-azide The concentration of cop...

Embodiment 2

[0056] In the present embodiment, the synthesis process of the four-arm polylactide-polyethylene glycol-azide copolymer is:

[0057] i) Synthesis of linear polyethylene lactide-polyethylene glycol-azide copolymer: add 0.008mol monomethyl ether polyethylene glycol (M w =500~1200), heat to melt, then add lactide and glycolide, heat to melt completely under the protection of dry nitrogen, add 0.01g stannous octoate, raise the temperature to 140°C, react for 10h, add di Chloromethane and glacial ether were purified to obtain intermediate product 1 (dissolve the product with dichloromethane first, then add glacial ether, the amount of glacial ether added is more than 10 times the volume of dichloromethane, take the precipitate, and vacuum Drying, it is the intermediate product 1); the obtained intermediate product 1 is dissolved in dichloromethane, and the dissolution is completed, stirred under the protection of nitrogen, adding 0.001mol triethylamine, adding methanesulfonyl chlor...

Embodiment 3

[0063] In the present embodiment, the synthesis process of the four-arm polylactide-polyethylene glycol-azide copolymer is:

[0064] i) Synthesis of linear polyethylene lactide-polyethylene glycol-azide copolymer: add 0.008mol monomethyl ether polyethylene glycol (M w =500~1200), heat to melt, add lactide and glycolide, heat to melt completely under the protection of dry nitrogen, add 0.01g stannous octoate, raise the temperature to 160°C, react for 6 hours, add di Chloromethane and glacial ether were purified to obtain intermediate product 1 (the product was first dissolved with dichloromethane, and then glacial ether was added. The amount of glacial ether added was more than 10 times the volume of dichloromethane, and the precipitate was taken under vacuum at 60 ° C. Drying, it is the intermediate product 1); the obtained intermediate product 1 is dissolved in dichloromethane, and the dissolution is completed, stirred under the protection of nitrogen, adding 0.001mol of trie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com