Mine use cable sheath material and preparation method thereof

A cable sheathing material and mine-used technology, which is applied in the direction of circuits, electrical components, plastic/resin/wax insulators, etc., can solve the problems of unsatisfactory extrusion effect of chlorinated polyethylene compounded rubber, and it is easy to achieve the mixing parameters Good control and processing extrusion performance, excellent aging resistance and ozone resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

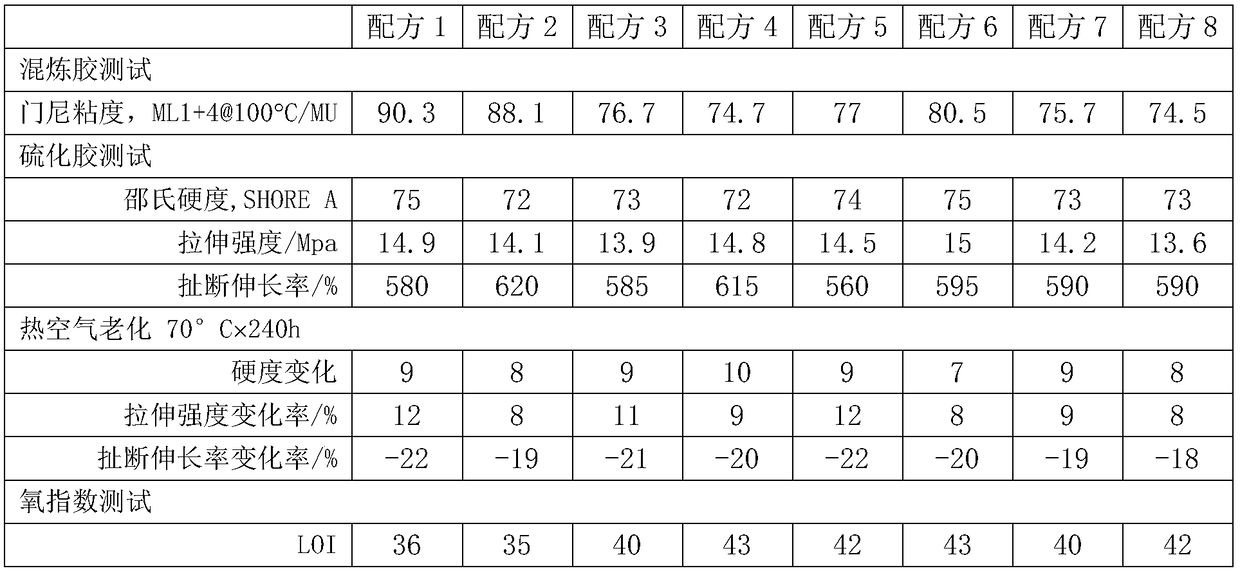

[0023] An embodiment of the present invention provides a cable sheathing material for mine use, which includes the following components in mass fractions: 100 parts of chlorinated polyethylene rubber, 3 parts of peroxide vulcanizing agent, 2 parts of vulcanization aid, 10 parts of magnesium oxide, 20 parts of carbon black, 30 parts of white carbon black, 4 parts of vinyl tris (2-methoxyethoxy) silane, 10 parts of aluminum hydroxide, 40 parts of chlorinated paraffin, 10 parts of dioctyl sebacate, three 3 parts of antimony oxide, 4 parts of calcium stearate, 4 parts of styrene resin, 1.5 parts of octadecyl primary amine, 6 parts of tributoxyethyl phosphate, 3 parts of Aktiplast M.

[0024] The above components are prepared according to the following steps:

[0025] The first step, a mastication: set the circulating water temperature of the internal mixer to 40°C, according to the filling factor of 0.85, weigh chlorinated polyethylene rubber and put it into the internal mixer for...

Embodiment 2

[0030] An embodiment of the present invention provides a cable sheathing material for mine use, which includes the following components in mass fractions: 100 parts of chlorinated polyethylene rubber, 2 parts of peroxide vulcanizing agent, 1.5 parts of vulcanization aid, 9 parts of magnesium oxide, 10 parts of carbon black, 15 parts of white carbon black, 2 parts of vinyl tris (2-methoxyethoxy) silane, 20 parts of aluminum hydroxide, 20 parts of chlorinated paraffin, 20 parts of dioctyl sebacate, three 2 parts of antimony oxide, 3 parts of calcium stearate, 3 parts of styrene resin, 1.2 parts of octadecyl primary amine, 5 parts of tributoxyethyl phosphate, 2 parts of Aktiplast M.

[0031] The above components are prepared according to the following steps:

[0032] The first step, a mastication: set the circulating water temperature of the internal mixer to 35°C, according to the filling factor of 0.9, weigh chlorinated polyethylene rubber and put it into the internal mixer for...

Embodiment 3

[0037] An embodiment of the present invention provides a cable sheathing material for mine use, which includes the following components in mass fractions: 100 parts of chlorinated polyethylene rubber, 4 parts of peroxide vulcanizing agent, 3 parts of vulcanization auxiliary agent, 12 parts of magnesium oxide, 15 parts of carbon black, 25 parts of white carbon black, 3 parts of vinyl tris (2-methoxyethoxy) silane, 15 parts of aluminum hydroxide, 35 parts of chlorinated paraffin, 15 parts of dioctyl sebacate, three 4 parts of antimony oxide, 5 parts of calcium stearate, 5 parts of styrene resin, 2 parts of octadecyl primary amine, 8 parts of tributoxyethyl phosphate, 4 parts of Aktiplast M.

[0038] The above components are prepared according to the following steps:

[0039] The first step, a mastication: set the circulating water temperature of the internal mixer to 45°C, according to the filling factor of 0.8, weigh chlorinated polyethylene rubber and put it into the internal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com