Recycling method for lithium iron manganese phosphate positive electrode material for battery

A technology of lithium iron manganese phosphate and battery cathode, which is applied in the field of recycling and utilization of cathode materials of lithium iron manganese phosphate batteries, can solve the problems of low self-discharge rate, low cost, insufficient rate performance, etc., so as to avoid pollution and shorten service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

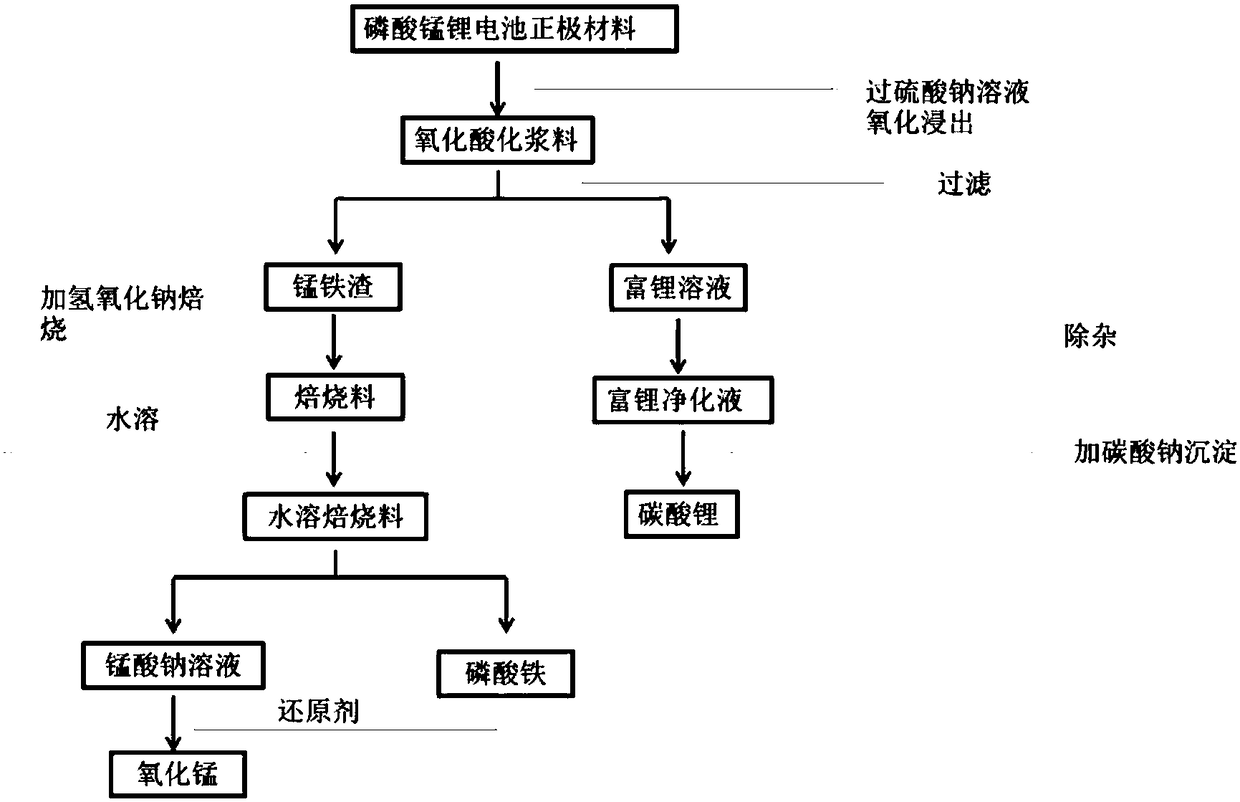

[0028] Such as figure 1 As shown, the positive electrode material of lithium manganese iron phosphate battery is first dissolved in sodium persulfate solution, and the oxidative acidification slurry is obtained through oxidation reaction, and then the lithium-rich solution and ferromanganese slag are obtained through filtration, and the ferromanganese slag is manganese oxide and ferric phosphate The mixture of lithium-rich solution is removed to obtain lithium-rich purification solution, and the lithium-rich purification solution is precipitated by sodium carbonate solution to obtain lithium carbonate; ferromanganese slag is roasted with sodium hydroxide solid at a roasting temperature of 450 ° C, and the obtained roasted material is dissolved in water to obtain water-soluble The roasting material, the water-soluble roasting material is filtered to obtain sodium manganate solution and iron phosphate; the sodium manganate solution is added with reducing agent manganese trioxide ...

Embodiment 2

[0032] Such as figure 1 As shown, the positive electrode material of lithium manganese iron phosphate battery is first dissolved in sodium persulfate solution, and the oxidative acidification slurry is obtained through oxidation reaction, and then the lithium-rich solution and ferromanganese slag are obtained through filtration, and the ferromanganese slag is manganese oxide and ferric phosphate The mixture of lithium-rich solution is obtained by removing impurities, and the lithium-rich purified solution is precipitated by sodium carbonate solution to obtain lithium carbonate; the ferromanganese slag is roasted with sodium hydroxide solid, the roasting temperature is 500 ° C, and the obtained roasted material is dissolved in water to obtain water-soluble The roasting material, the water-soluble roasting material is filtered to obtain sodium manganate solution and iron phosphate; the sodium manganate solution is added with reducing agent manganese trioxide to obtain manganese d...

Embodiment 3

[0036] Such as figure 1 As shown, the positive electrode material of lithium manganese iron phosphate battery is first dissolved in sodium persulfate solution, and the oxidative acidification slurry is obtained through oxidation reaction, and then the lithium-rich solution and ferromanganese slag are obtained through filtration, and the ferromanganese slag is manganese oxide and ferric phosphate The mixture of lithium-rich solution is obtained by removing impurities, and the lithium-rich purified solution is precipitated by sodium carbonate solution to obtain lithium carbonate; the ferromanganese slag is roasted with sodium hydroxide solid, the roasting temperature is 500 ° C, and the obtained roasted material is dissolved in water to obtain water-soluble The roasting material, the water-soluble roasting material is filtered to obtain sodium manganate solution and iron phosphate; the sodium manganate solution is added with reducing agent manganese trioxide to obtain manganese d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com