Process for processing and packaging honey

A packaging process, honey technology, applied in the functions of food ingredients, food science, application, etc., can solve the problems of single health care effect, difficult taste and nutrition, etc., and achieve the effect of enhancing immunity, good taste and improving honey concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

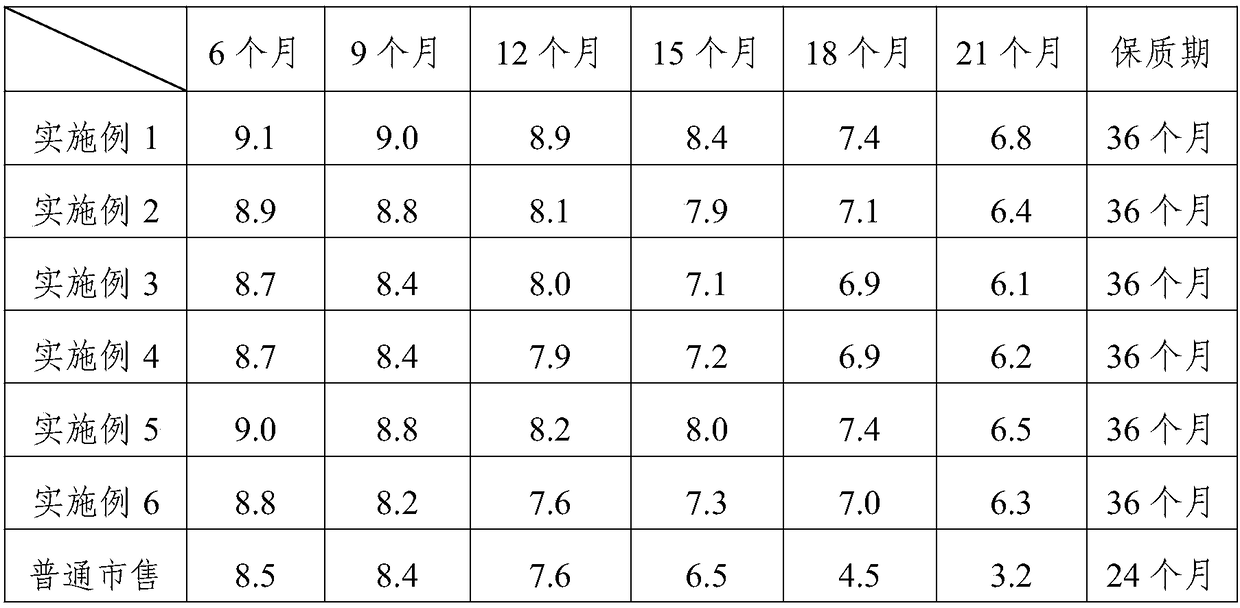

Examples

Embodiment 1

[0023] A kind of processing of honey and packaging technology thereof, comprises the following steps:

[0024] (1) heating the original honey to 50° C., and filtering it once to remove impurities; then continue heating the honey after the first filtering to 68° C., and carry out secondary filtration with a 70-mesh filter screen;

[0025] (2) Carry out vacuum concentration to the honey after described secondary filtration, after concentration, cool down to 23 DEG C, add the crystal seed that quality is the honey total mass 10% after vacuum concentration (the crystal seed is the natural crystal of initial honey, particle size is 20 μm), the quality is respectively 0.1% and 0.2% of the total mass of honey after vacuum concentration, mixed with lentinan and pachyphyllin, dibutylhydroxytoluene, vitamin A, propyl p-hydroxybenzoate, and natamycin, and mixed quickly and evenly , to get the honey mixture;

[0026] (3) Control the temperature of the honey mixture to 18° C., 1 to 2 days...

Embodiment 2

[0029] A kind of processing of honey and packaging technology thereof, comprises the following steps:

[0030] (1) heating the original honey to 45° C., and filtering it once to remove impurities; then continue heating the honey after the first filtering to 65° C., and carry out secondary filtration with an 80-mesh filter screen;

[0031] (2) Carry out vacuum concentration to the honey after the secondary filtration, after concentration, cool down to 25 DEG C, add the crystal seed whose quality is 5% of the total mass of honey after vacuum concentration (the crystal seed is the natural crystal of the original honey, the particle size is 25 μm), the quality is respectively 0.2% and 0.1% of the total mass of honey after vacuum concentration, lentinan and pachyphyllan, vitamin A, vitamin C, vitamin E, propyl p-hydroxybenzoate, potassium sorbate, mixed quickly and evenly to obtain honey mixture;

[0032] (3) Control the temperature of the honey mixture to 15° C., 1 to 2 days afte...

Embodiment 3

[0035] A kind of processing of honey and packaging technology thereof, comprises the following steps:

[0036] (1) heating the original honey to 55° C., filtering once to remove impurities; then continuing to heat the honey after the first filtering to 70° C., and carrying out secondary filtration with a filter screen of 60 mesh;

[0037] (2) Carry out vacuum concentration to the honey after described secondary filtration, after concentration, cool down to 20 DEG C, the quality is the crystal seed of 15% of the total mass of honey after vacuum concentration (the crystal seed is the natural crystal of the original honey, and the particle diameter is 15 μm ), the quality is respectively 0.3% and 0.1% of the total mass of honey after vacuum concentration, lentinan and pachymane, dibutylhydroxytoluene, propyl p-hydroxybenzoate, potassium sorbate, natamycin, quickly and evenly mixed, get the honey mixture;

[0038] (3) Control the temperature of the honey mixture to 20° C., 1 to 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com