Refining method for phenolic wastewater and equipment

A refining method and technology for phenolic wastewater, applied in chemical instruments and methods, water pollutants, water/sewage treatment, etc., can solve problems such as high risk of secondary pollution, achieve the effect of broadening recycling channels and increasing yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

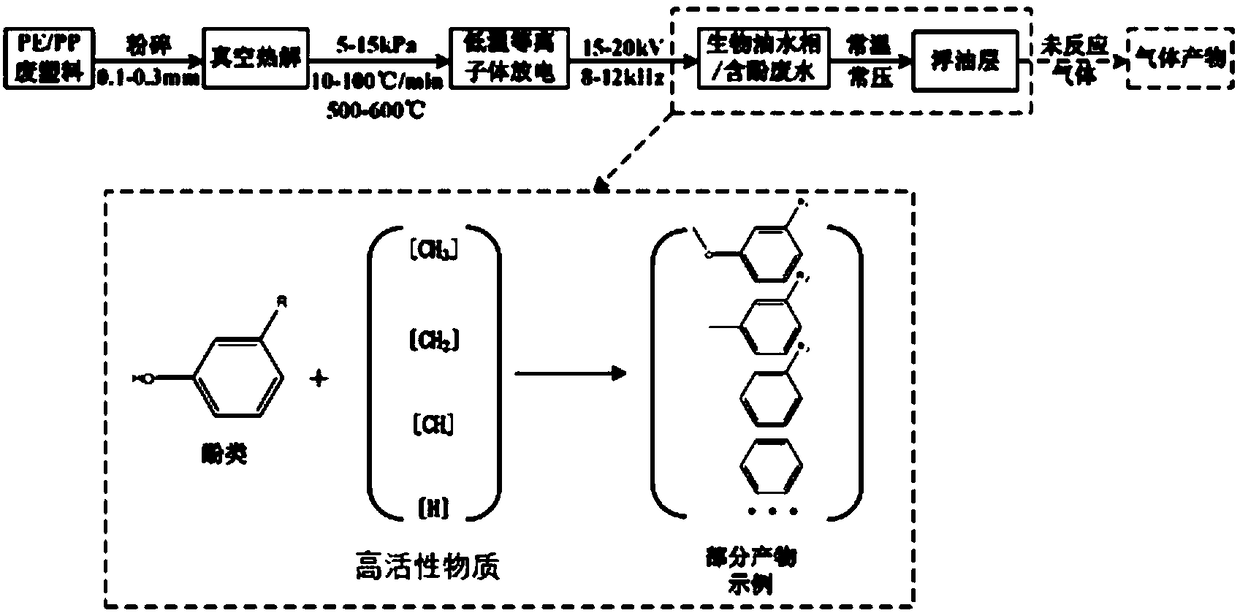

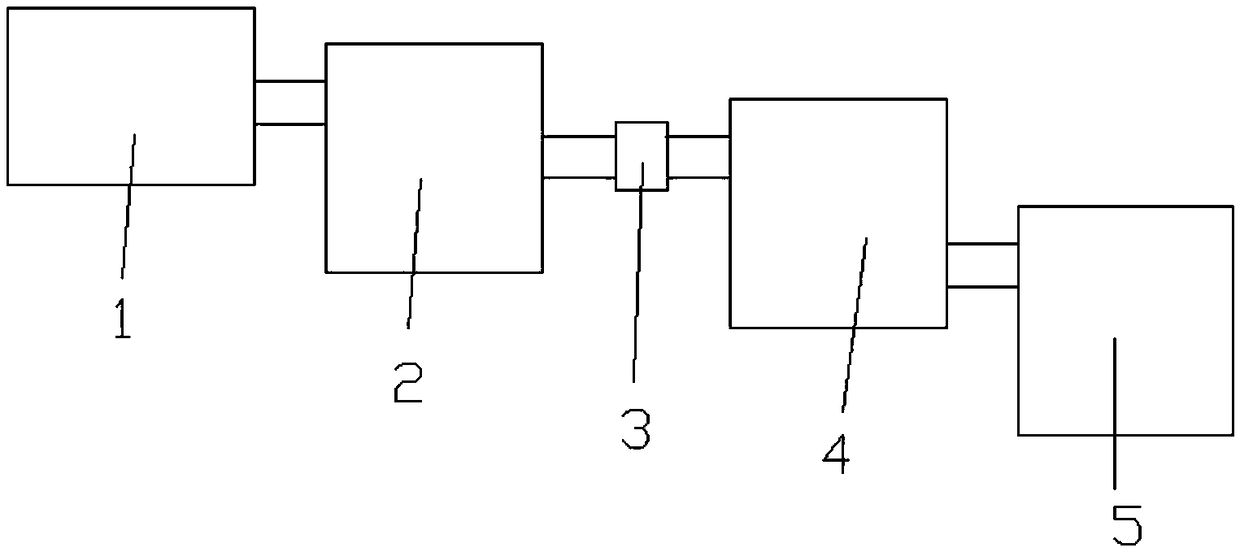

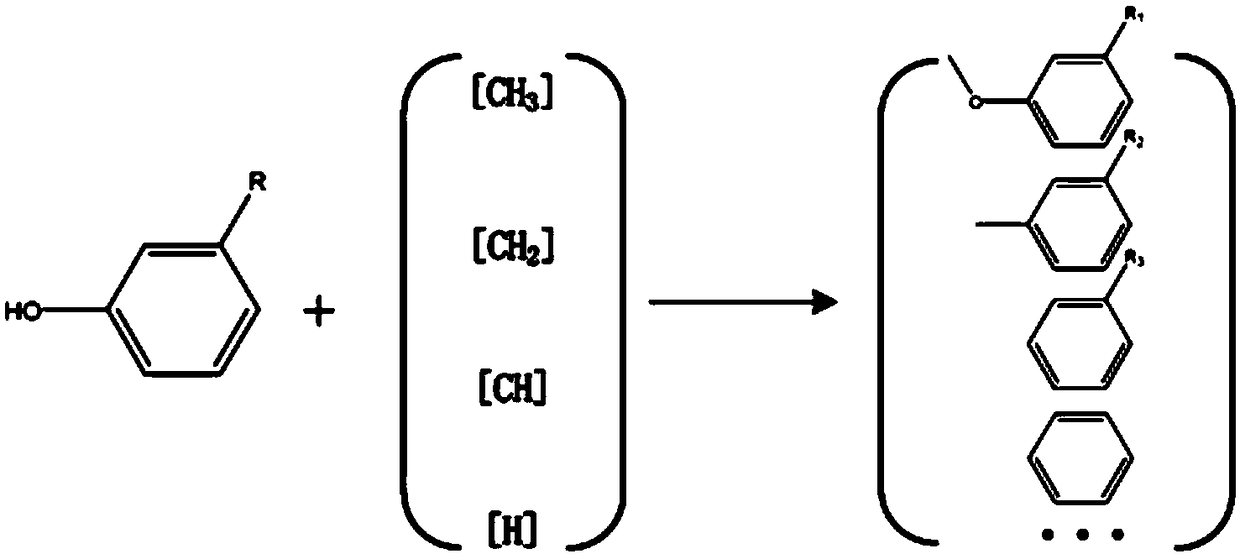

[0047] After pulverizing 300g polyethylene (PE) waste plastic to 0.1mm, fill it into a vacuum pyrolysis reactor, and then use vacuum pump suction to keep the pressure in the vacuum pyrolysis reactor at 5kPa and increase the temperature at a rate of 10℃ / min Start heating the waste plastics, and keep the final temperature at 500℃. The waste plastics are pyrolyzed to form steam. The pyrolysis gas passes through the dielectric barrier discharge type low-temperature plasma discharge reactor under the suction of the vacuum pump. The low-temperature plasma discharge reactor uses 15kV High voltage and 8kHz high frequency discharge the pyrolysis gas, and some ethylene molecules in the pyrolysis gas are activated and dissociated to produce CH 3 , CH 2 , CH, H and other highly active particle fragments, and then pass the pyrolysis gas rich in highly active substances into the 100mL bio-oil refined water phase, and contact with phenolic substances to remove their hydroxyl groups, and at the ...

Embodiment 2

[0054] After crushing 1000g of polypropylene (PP) waste plastic to 0.1mm, fill it into a vacuum pyrolysis reactor, and then use vacuum pump suction to maintain the pressure in the vacuum pyrolysis reactor at 15kPa, and increase the temperature at a rate of 50℃ / min Start heating the waste plastics, and keep the final temperature at 600℃. The waste plastics are pyrolyzed to form vapor. The pyrolysis gas passes through a dielectric barrier discharge type low-temperature plasma discharge reactor under the suction of a vacuum pump. The low-temperature plasma discharge reactor uses 20kV High voltage and 12kHz high frequency discharge the pyrolysis gas, and some ethylene molecules in the pyrolysis gas are activated and dissociated to produce CH 3 , CH 2 , CH, H and other high-active particle fragments, and then pass the pyrolysis gas rich in high-energy active substances into 300mL of the refined water phase of bio-oil, and contact with phenolic substances to remove their hydroxyl group...

Embodiment 3

[0061] The phenol reagent was added to pure water to prepare an aqueous solution containing phenol with a moderate concentration as the treatment object of the experiment.

[0062] After crushing 300g polyethylene (PE) and 300g polypropylene (PP) waste plastics to 0.1mm and mixing them, fill them into a vacuum pyrolysis reactor, and then use vacuum pump suction to keep the pressure in the vacuum pyrolysis reactor at 10kPa, and Start heating the waste plastic at a heating rate of 30°C / min, and keep the final temperature at 550°C. The waste plastic is pyrolyzed to form vapor. The pyrolysis gas passes through a dielectric barrier discharge type low-temperature plasma discharge reactor under the suction of a vacuum pump. The low-temperature plasma discharge reactor discharges the pyrolysis gas with a high voltage of 18kV and a high frequency of 10kHz. Part of the ethylene and propylene molecules in the pyrolysis gas are activated and dissociated to produce CH 3 , CH 2 , CH, H and othe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com