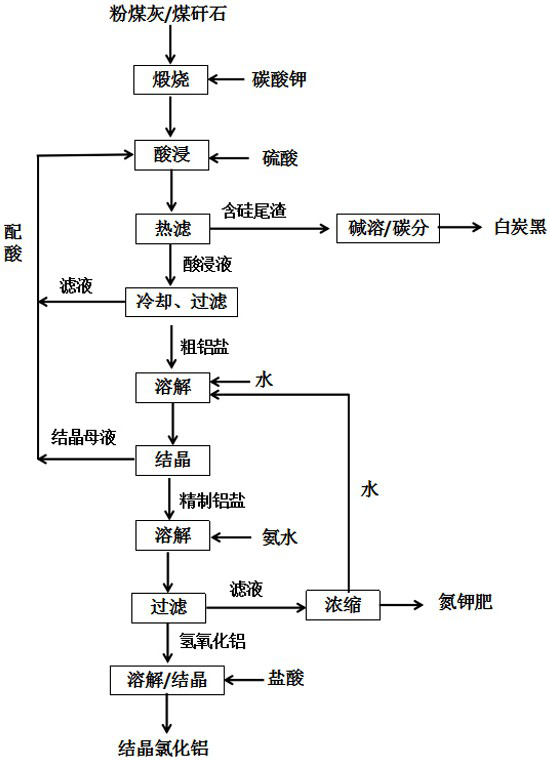

Method for preparing crystalline aluminum chloride and white carbon black from fly ash or coal gangue

A technology for crystallizing aluminum chloride and coal gangue, applied in chemical instruments and methods, aluminum chloride, aluminum halide, etc., can solve the problems of secondary pollution, complex technical process, high energy and material consumption, and achieve no three-waste discharge and process. Simple, cost-effective results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

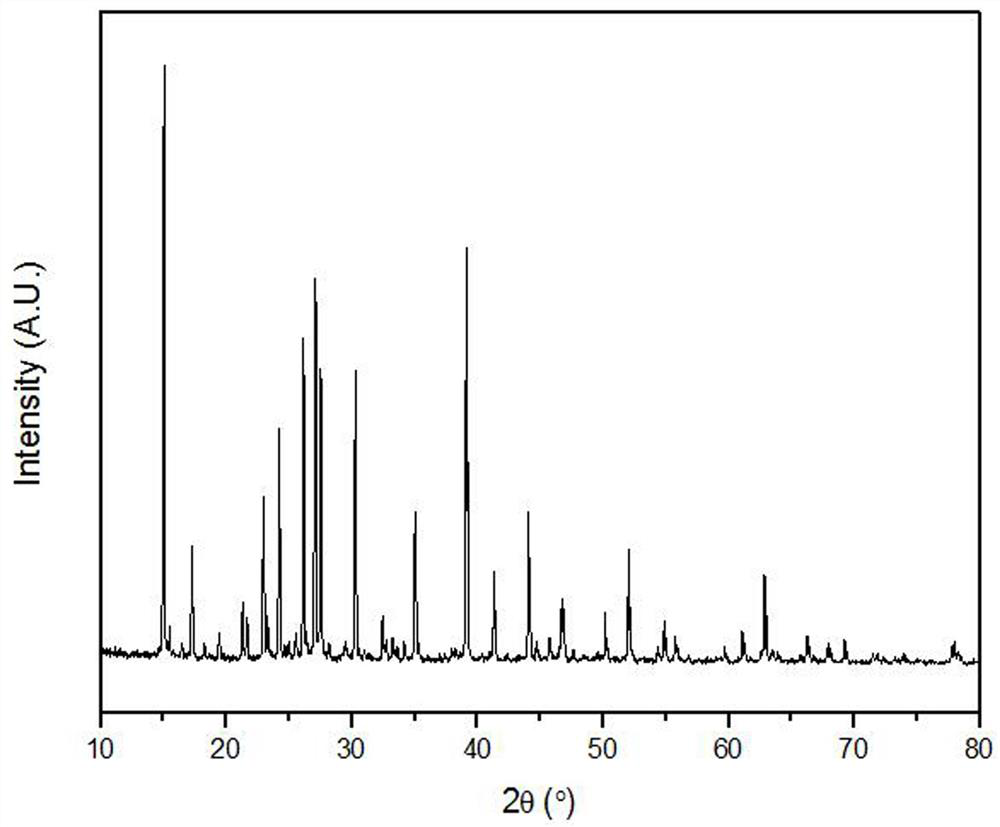

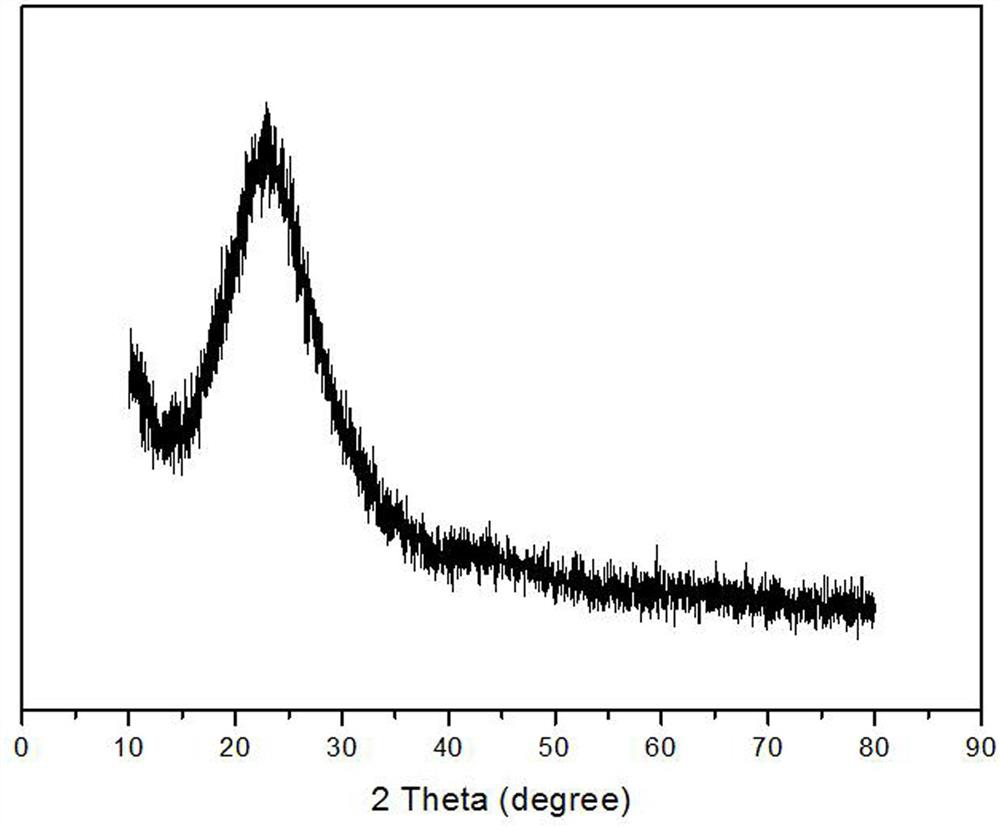

Embodiment 1

[0032] Take 100g of fly ash, add 54g of potassium carbonate, mix thoroughly, calcinate at 850°C for 3 hours, and cool to obtain sintered clinker; add 520mL of 40% sulfuric acid to the sintered clinker, heat up to 120°C for 2 hours, and dissolve the reactant , after the reaction is completed, heat filter to obtain silicon-containing tailings; naturally cool the filtrate to obtain crude aluminum salt, dissolve the crude aluminum salt in hot water at 80°C, keep stirring for 3 hours, then cool to below 20°C, stand still, and filter to obtain Refined aluminum salt, refined aluminum salt is dissolved with 10% ammonia water, separated by sedimentation and washed to obtain aluminum hydroxide, aluminum hydroxide is then dissolved with 20% hydrochloric acid, evaporated and concentrated at 60°C, separated by sedimentation, saturated aluminum chloride After the solution is washed, crystalline aluminum chloride is obtained; the silicon-containing tailings are dissolved with 20% NaOH solutio...

Embodiment 2

[0034] Take 100g of fly ash, add 63g of potassium carbonate, mix thoroughly, calcinate at 900°C for 3 hours, and cool to obtain sintered clinker; add 550mL of 50% sulfuric acid to the sintered clinker, heat up to 130°C for 3 hours, and dissolve the reactant , after the reaction is completed, heat filter to obtain silicon-containing tailings; naturally cool the filtrate to obtain crude aluminum salt, dissolve the crude aluminum salt in hot water at 90°C, keep stirring for 1 hour, then cool to below 20°C, stand and filter to obtain Refined aluminum salt, refined aluminum salt is eluted with 8% dilute ammonia water, separated by sedimentation, washed to obtain aluminum hydroxide, aluminum hydroxide is then dissolved with 25% hydrochloric acid, concentrated by evaporation at 80°C, separated by sedimentation, saturated aluminum chloride After the solution is washed, crystalline aluminum chloride is obtained; the silicon-containing tailings are dissolved with 20% NaOH solution at 100...

Embodiment 3

[0036] Take 100g of coal gangue, add 70g of potassium carbonate, mix thoroughly, calcinate at 920°C for 3 hours, and cool to obtain sintered clinker; add 620mL of 60% sulfuric acid to the sintered clinker, heat up to 100°C for 2 hours, and dissolve the reactant. After the reaction is completed, heat filter to obtain silicon-containing tailings; naturally cool the filtrate to obtain crude aluminum salt, dissolve the crude aluminum salt in hot water at 70°C, keep stirring for 2 hours, then cool to below 20°C, stand still, and filter to obtain refined Aluminum salt, refined aluminum salt is eluted with 15% ammonia water, separated by sedimentation and washed to obtain aluminum hydroxide, which is then dissolved with 23% hydrochloric acid, concentrated by evaporation at 90°C, separated by sedimentation, and washed with saturated aluminum chloride solution Finally, crystalline aluminum chloride is obtained; the silicon-containing tailings are dissolved with 20% NaOH solution at 100°...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com