Method for BAME treatment and recycling of printing and dyeing wastewater

A technology for printing and dyeing wastewater and wastewater, applied in textile industry wastewater treatment, multi-stage water treatment, water/sewage treatment, etc. The effect of prolonging the service life and improving the quality of the influent water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

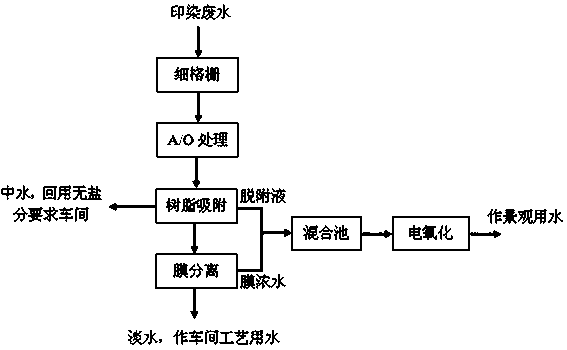

Method used

Image

Examples

Embodiment 1

[0023] 1) Printing and dyeing wastewater volume 3000~4000m 3 / d, water COD Cr About 1780~1860mg / L, TDS about 3420~4330mg / L;

[0024] After anaerobic granular sludge hydrolysis and aerobic granular sludge oxidation treatment, the biodegradable pollutants in the wastewater are decomposed by microorganisms. The anaerobic granular sludge load is 1.92~2.40 kgCOD / m 3 d, the load of aerobic granular sludge is 0.3~0.60kgCOD / m 3 d;

[0025] 2) Biological method effluent COD Cr About 120~180mg / L, treated by macroporous weakly basic resin adsorption method, the cross-sectional flow rate of the adsorption bed is 4~6m / h; when the resin reaches adsorption saturation, it is eluted with 3.0% dilute alkali solution, and then washed with water to After neutralization, it can be recycled, and the desorption liquid can be electro-oxidized;

[0026] 3) Effluent COD with low pollutant concentration obtained by resin adsorption method Cr About 80~100mg / L, enter the reverse osmosis membrane pro...

Embodiment 2

[0029] 1) Printing and dyeing wastewater volume 1300~1500m 3 / d, water COD Cr About 780~1050mg / L, TDS about 2760~3130mg / L, first undergo anaerobic granular sludge hydrolysis and aerobic granular sludge oxidation treatment, and decompose biodegradable pollutants in wastewater by microorganisms;

[0030] 2) Biological method effluent CODCr About 93~126mg / L, treated by macroporous weakly basic resin adsorption method, the cross-sectional flow rate of the adsorption bed is 8~10m / h; when the resin reaches adsorption saturation, use 2.0% dilute alkali solution for elution, and then wash with water until After neutralization, it can be recycled, and the desorption liquid can be electro-oxidized;

[0031] 3) Effluent COD with low pollutant concentration obtained by resin adsorption method Cr About 65 ~ 83mg / L, enter the reverse osmosis membrane process, the operating parameters are the same as in Example 1, to obtain fresh water and concentrated water, fresh water COD Cr 32~45mg / L,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com