Modified nano-polystyrene reinforced and toughened epoxy resin composite nano-material and preparation method thereof

A technology of nano-composite materials and tough epoxy resin, which is applied in the field of modified nano-polystyrene reinforced and toughened epoxy resin nano-composites and its preparation, which can solve the problems of high surface energy, large particle size and high content of polystyrene problems, to achieve the effects of improved tensile strength and toughness, improved tensile elongation, and good interfacial compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Example 1, 1 weight part of polystyrene is added to 2500 weight parts of cyclohexane (volume fraction 20%), acetone (volume fraction 30%), ethyl acetate (volume fraction 50%) mixed solution, magnetic Stir until completely dissolved. Add 3 parts by weight of 5% anhydrous aluminum chloride / ethanol solution, and react for 1 h under magnetic stirring. Then add 2 parts by weight of epichlorohydrin, and react for 0.5 h under magnetic stirring. After the reaction is complete, wash, dry and grind to obtain modified polystyrene powder.

[0018] Add 5 parts by weight of modified polystyrene powder to 70 parts by weight of N,N-dimethylformamide (DMF). Then magnetically stirred for 3 h, and after complete dissolution, polystyrene microspheres were obtained by electrospinning. Electrospinning parameters were as follows: polymer concentration 2%, propulsion speed 0.05 μl / min, electrostatic voltage 10 kV, receiving distance 15 cm.

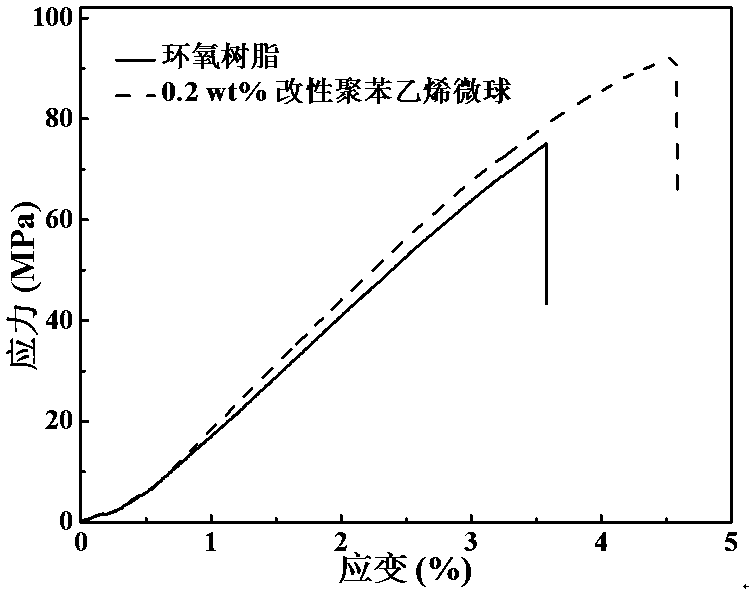

[0019] Add 0.2 parts by weight of nano polystyre...

Embodiment 2

[0021] Example 2, 20 parts by weight of polystyrene is added to 3000 parts by weight of cyclohexane (volume fraction 10%), acetone (volume fraction 40%), ethyl acetate (volume fraction 50%) mixed solution, magnetic Stir until completely dissolved. Add 5 parts by weight of 7% anhydrous aluminum chloride / ethanol solution, and react for 1 h under magnetic stirring. Then add 3 parts by weight of epichlorohydrin, and react for 1 h under magnetic stirring. After the reaction is complete, wash, dry and grind to obtain modified polystyrene powder.

[0022] Add 25 parts by weight of modified polystyrene powder to 75 parts by weight of N,N-dimethylformamide (DMF). Then magnetically stirred for 5 h, and after complete dissolution, polystyrene microspheres were obtained by electrospinning. The electrospinning parameters were: polymer concentration 6%, propulsion speed 0.2 μl / min, electrostatic voltage 15 kV, receiving distance 25 cm.

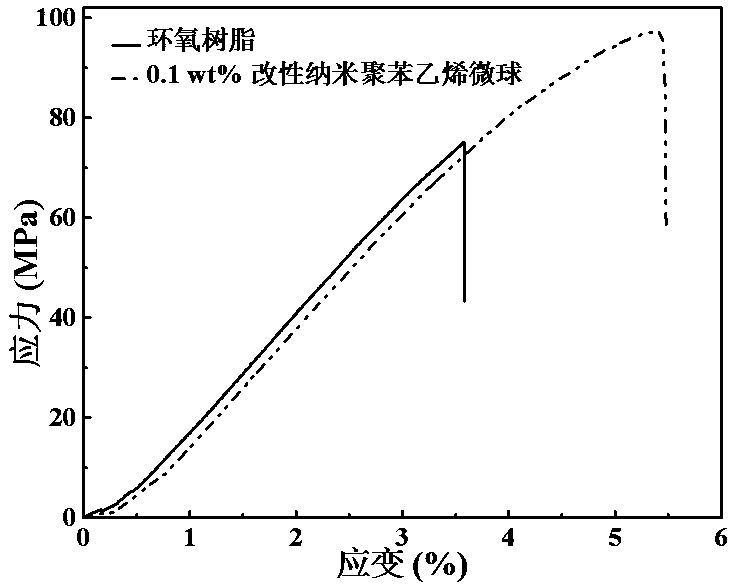

[0023] Add 0.1 parts by weight of nano polystyren...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com