Composite thermal insulating strip for building doors and windows and preparation method of composite thermal insulating strip

A technology for building doors and windows and heat insulation strips, which is applied in the field of composite heat insulation strips for building doors and windows and its preparation, can solve the problems of poor dimensional stability, low tensile strength, and difficult processing, and achieve high tensile strength and tensile strength. Excellent performance and fracture resistance, good mechanical toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

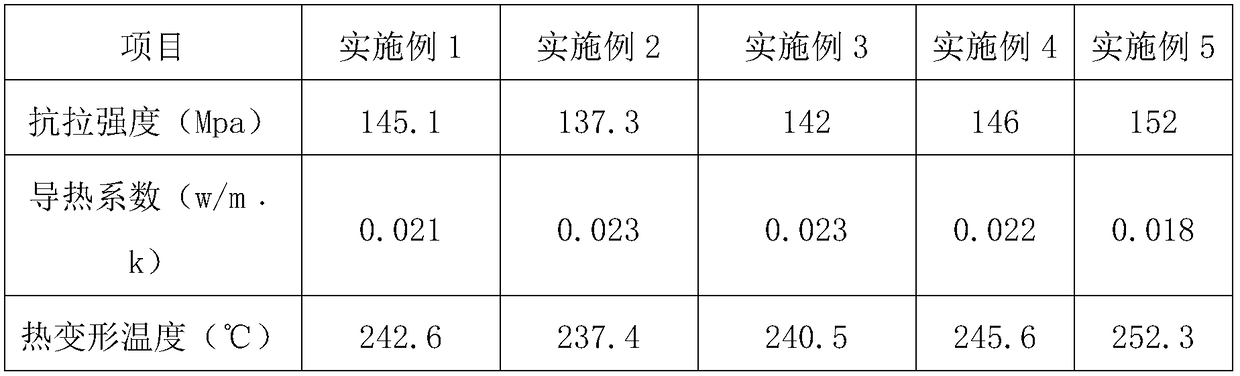

Examples

Embodiment 1

[0026] A composite heat insulation strip for building doors and windows, comprising the following raw materials in parts by weight:

[0027] 75 parts of nylon resin, 10 parts of epoxy soybean oil, 5 parts of epoxy fatty acid methyl ester, 5 parts of propylene-ethylene graft copolymer, 15 parts of glass fiber, 15 parts of sepiolite fiber, 8 parts of basalt fiber, 7 parts of nano titanium dioxide 8 parts, 8 parts of nano-mica powder, 3 parts of color masterbatch, 3 parts of phosphate ester, 2 parts of phosphite, 1.8 parts of antioxidant, 2.5 parts of lubricant and 1.2 parts of silane coupling agent.

[0028] The antioxidant is butyl hydroxyanisole.

[0029] The lubricant is silicone oil.

[0030] The silane coupling agent is γ-glycidyl etheroxypropyltrimethoxysilane.

[0031] The preparation method of the composite insulation strip for building doors and windows in the present embodiment, specifically, comprises the following steps:

[0032] (1) Add glass fiber, sepiolite fib...

Embodiment 2

[0037] A composite heat insulation strip for building doors and windows, comprising the following raw materials in parts by weight:

[0038] 80 parts of nylon resin, 15 parts of epoxy soybean oil, 9 parts of epoxy fatty acid methyl ester, 9 parts of propylene-ethylene graft copolymer, 20 parts of glass fiber, 20 parts of sepiolite fiber, 15 parts of basalt fiber, 12 parts of nano titanium dioxide 12 parts, 12 parts of nano-mica powder, 7 parts of color masterbatch, 7 parts of phosphate ester, 5 parts of phosphite, 2.8 parts of antioxidant, 4.2 parts of lubricant and 2.5 parts of silane coupling agent.

[0039] The antioxidant is dibutyl hydroxytoluene.

[0040] The lubricant is a fatty acid amide.

[0041] The silane coupling agent is γ-aminopropyltriethoxysilane.

[0042] The preparation method of the composite insulation strip for building doors and windows in the present embodiment, specifically, comprises the following steps:

[0043] (1) Add glass fiber, sepiolite fibe...

Embodiment 3

[0048] A composite heat insulation strip for building doors and windows, comprising the following raw materials in parts by weight:

[0049] 76 parts of nylon resin, 12 parts of epoxy soybean oil, 6 parts of epoxy fatty acid methyl ester, 6 parts of propylene-ethylene graft copolymer, 17 parts of glass fiber, 16 parts of sepiolite fiber, 11 parts of basalt fiber, 9 parts of nano titanium dioxide 9 parts, 9 parts of nano-mica powder, 4 parts of masterbatch, 4 parts of phosphate ester, 3 parts of phosphite, 2.2 parts of antioxidant, 3.2 parts of lubricant and 1.8 parts of silane coupling agent.

[0050] The antioxidant is tert-butyl hydroquinone.

[0051] The lubricant is polytetrafluoroethylene.

[0052] The silane coupling agent is γ-(methacryloyloxy)propyltrimethoxysilane.

[0053] The preparation method of the composite insulation strip for building doors and windows in the present embodiment, specifically, comprises the following steps:

[0054] (1) Add glass fiber, sepiol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com