Pasteurization modified milk, hot brewing milk tea containing pasteurization modified milk, and preparation process thereof

A pasteurization and preparation technology, applied in dairy products, milk preservation, milk preparations, etc., can solve the problems of heavy sugar-sweetened condensed milk, high viscosity, inconvenient eating, etc., and achieve the effect of reducing investment in production equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

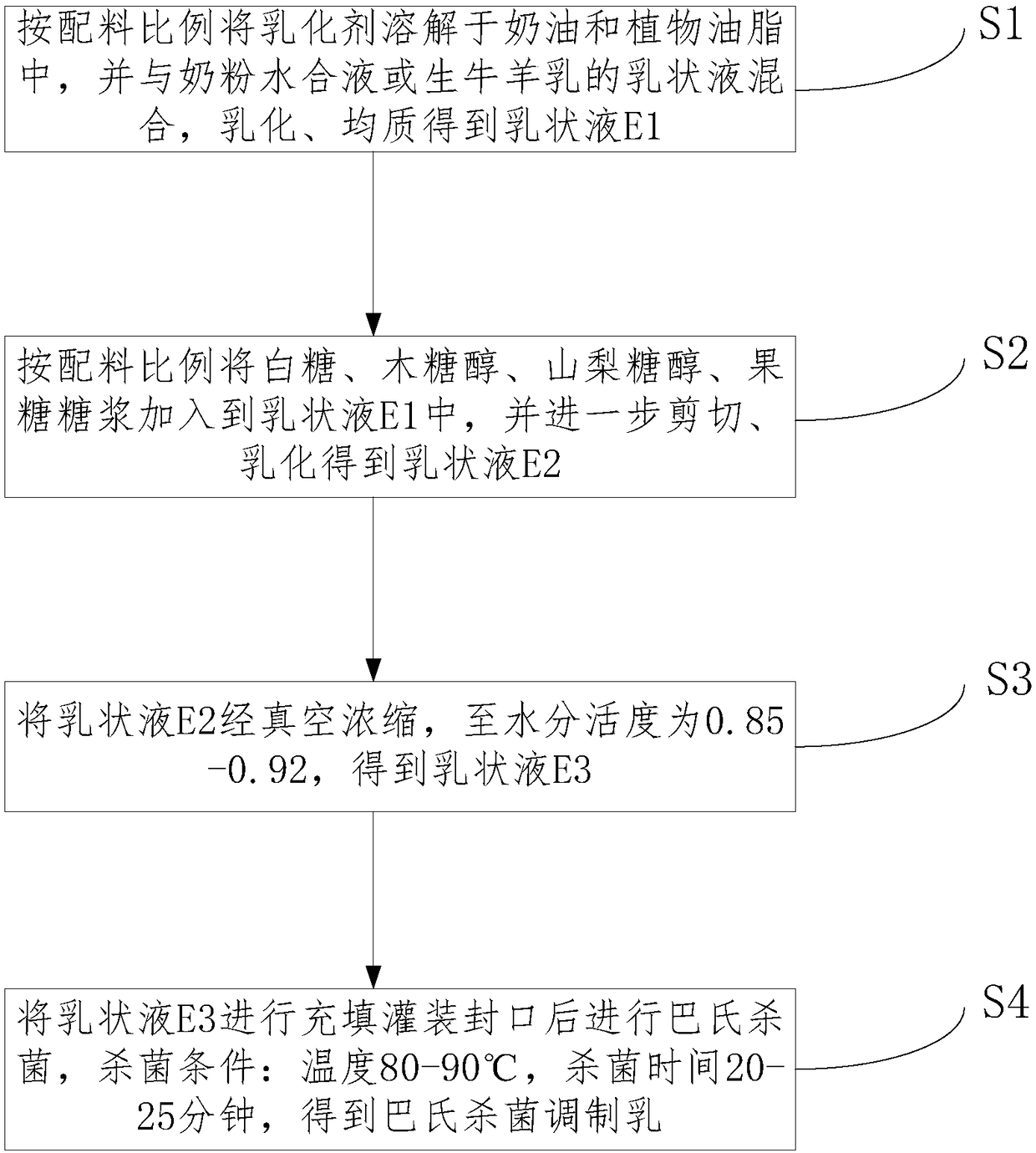

[0088] according to figure 1 Shown is a method for preparing pasteurized modulated milk according to an embodiment of the present invention. This example provides a preparation process for pasteurized modulated milk, which specifically includes the following steps:

[0089]S1. Dissolve 1.5 parts of lipophilic emulsifier in 2 parts of anhydrous butter and 2 parts of hydrogenated coconut oil, mix with milk powder hydration solution, emulsify and homogenize to obtain emulsion E11;

[0090] S11. Emulsifier dissolution: heat 2 parts of hydrogenated coconut oil and 2 parts of anhydrous butter to 50-60°C, add 0.5 part of lipophilic emulsifier mono-diglyceride and 1 part of sodium stearoyl lactylate to the heated oil , stir until completely dissolved to obtain a grease solution;

[0091] S12. Milk powder hydration: Add 12 parts of whole milk powder and 2.5 parts of sodium caseinate into 40 parts of warm water at 65°C, then stir until the milk powder and sodium caseinate are fully dis...

Embodiment 2

[0104] according to figure 1 Shown is a method for preparing pasteurized modulated milk according to an embodiment of the present invention. This example provides a preparation process for pasteurized modulated milk, which specifically includes the following steps:

[0105] S1. Dissolve 1.5 parts of lipophilic emulsifier in 2 parts of anhydrous butter and 2 parts of hydrogenated coconut oil, mix with raw milk, emulsify and homogenize to obtain emulsion E21;

[0106] S11. Emulsifier dissolution: Heat 2 parts of hydrogenated coconut oil and 2 parts of anhydrous butter to 50-60°C, add 0.5 part of lipophilic emulsifier mono-diglyceride and 1 part of sodium stearoyl lactylate to the heated oil , stir until the emulsifier is completely dissolved to obtain a grease solution;

[0107] S12. Heat 96 parts of raw milk to 65°C, add 2.5 parts of sodium caseinate until the sodium caseinate dissolves to obtain a raw milk emulsion;

[0108] S13. Pour the fat solution obtained in S11 into th...

Embodiment 3

[0120] according to figure 1 Shown is a method for preparing pasteurized modulated milk according to an embodiment of the present invention. This example provides a preparation process for pasteurized modulated milk, which specifically includes the following steps:

[0121] S1. Dissolve 0.6 part of mono-diglyceride and 0.5 part of sodium lactate stearate in 2 parts of anhydrous cream and 2 parts of palm oil, mix with raw goat milk, emulsify and homogenize to obtain emulsion E31;

[0122] S11. Dissolving emulsifier: Heat 2 parts of palm oil and 2 parts of anhydrous butter to 50-60°C, add 0.6 part of mono-diglyceride and 0.5 part of sodium stearic acid lactate into the heated oil, and stir until emulsifier Completely dissolve to obtain a grease solution;

[0123] S12. Heat 96 parts of raw goat milk to 65°C, then add 0.4 parts of sucrose ester and 2.5 parts of sodium caseinate as a hydrophilic emulsifier until the emulsifier and sodium caseinate are dissolved to obtain an emulsi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com