Bismuth titanate/bismuth oxide photocatalyst as well as preparation method and application thereof

A photocatalyst, bismuth oxide technology, applied in physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, etc., can solve the problem of low photocatalytic activity of pure bismuth oxide, etc. The effect of improving photocatalytic activity, improving catalytic activity, and improving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] The present invention also provides a method for preparing the bismuth titanate / bismuth oxide photocatalyst described in the above technical scheme, comprising the following steps:

[0038] (1) carry out liquid phase precipitation with bismuth nitrate, the γ-Bi that obtains 2 o 3 Roasting to obtain γ-Bi with high crystallinity 2 o 3 carrier;

[0039] (2) the γ-Bi with high degree of crystallinity obtained in the step (1) 2 o 3 The carrier is immersed in the mixed solution and subjected to aging treatment to obtain a photocatalyst precursor; the mixed solution includes bismuth nitrate, titanium salt and polyhydric alcohol solvent;

[0040] (3) The photocatalyst precursor that described step (2) is obtained is carried out drying and roasting treatment successively, obtains bismuth titanate / bismuth oxide photocatalyst;

[0041] The steps (1) and (2) are not limited in sequence.

[0042] In the present invention, bismuth nitrate is subjected to liquid phase precipita...

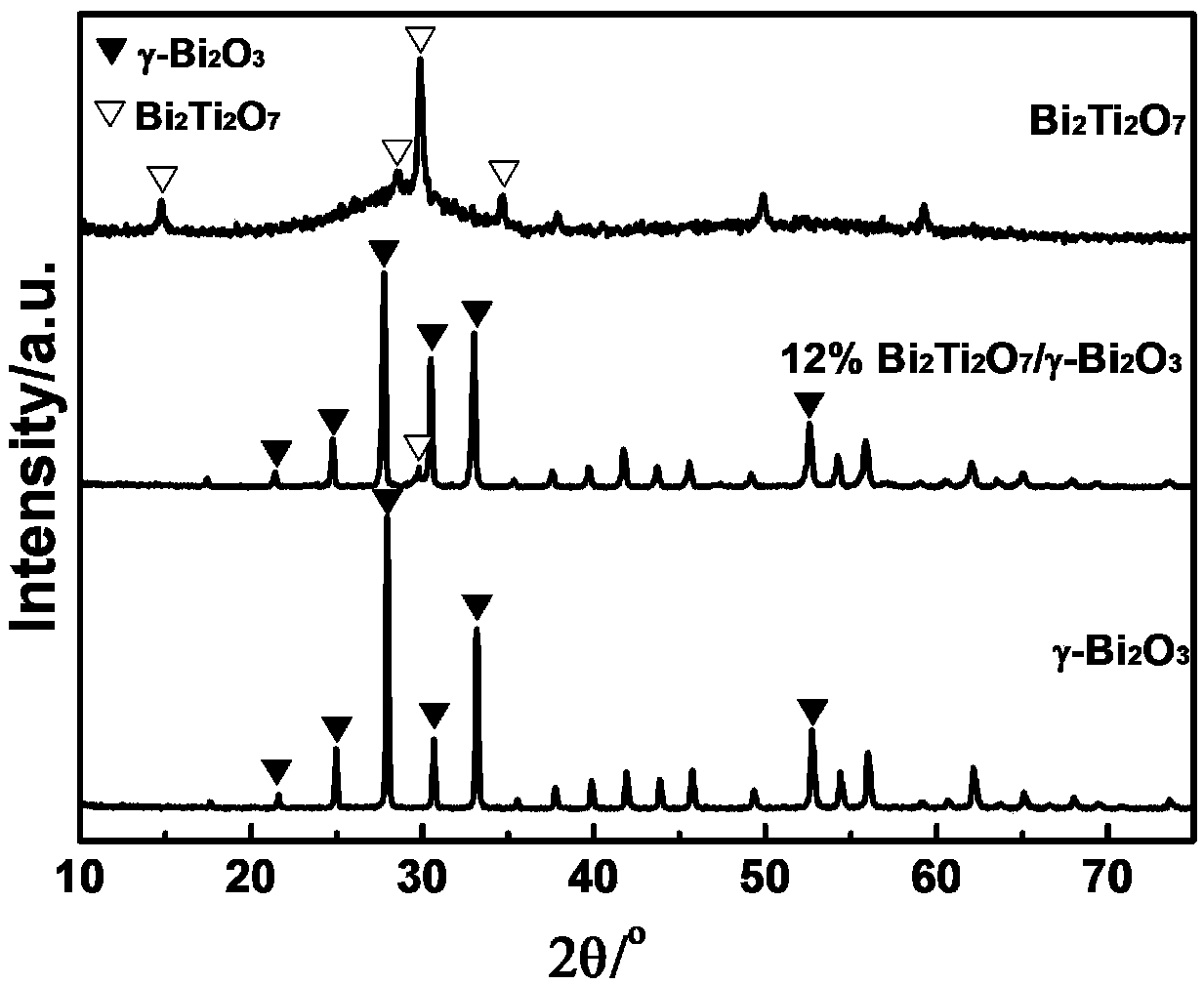

Embodiment 1

[0088] (1) Dissolve 10 g of bismuth nitrate pentahydrate in 0.5 mol / L dilute nitric acid and stir fully. After the solution is clarified, introduce it into a separatory funnel, and slowly add the solution dropwise into 1 mol / L sodium hydroxide solution. The solution is completely immersed in a water bath, the water bath is 65 ° C, about 20 minutes dropwise, and then reacted for 3 hours, the precipitate is first washed three times with deionized water, then washed twice with absolute ethanol, and then dried at 60 ° C to obtain γ-Bi 2 o 3 ;

[0089] (2) At a temperature of 600°C, the γ-Bi obtained in step (1) 2 o 3 Carry out roasting, roasting 4h, obtain γ-Bi 2 o 3 carrier;

[0090] (3) Dissolve 0.1457g bismuth nitrate pentahydrate in 2mL of a mixed solvent of ethylene glycol and ethanol (the volume ratio of ethylene glycol and ethanol is 3:1), add 0.1278mL tetrabutyl titanate, stir well, and then 1g γ-Bi 2 o 3 The carrier is immersed in this solvent, stirred, and aged ...

Embodiment 2

[0099] (1) Dissolve 10 g of bismuth nitrate pentahydrate in 1 mol / L dilute nitric acid and stir well. After the solution is clarified, introduce it into a separatory funnel, and slowly add the solution dropwise into 1 mol / L sodium hydroxide solution. Completely immerse in a water bath, the water bath is 75°C, add dropwise for about half an hour, then react for 3 hours, wash the precipitate with deionized water three times, then wash twice with absolute ethanol, and then dry it at 60°C to prepare γ-Bi 2 o 3 ;

[0100] (2) At a temperature of 550°C, the γ-Bi obtained in step (1) 2 o 3 Carry out roasting, roasting 2h, obtain γ-Bi 2 o 3 carrier;

[0101] (3) Dissolve 0.1457g of bismuth nitrate pentahydrate in 2mL of ethylene glycol solvent, add 0.298mL of titanium isopropoxide, stir well, and then add 1g of γ-Bi 2 o 3 The carrier is immersed in this solvent, stirred, and aged at room temperature for 24 hours. During this process, bismuth nitrate pentahydrate and titanium i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com