Double-metal MOF (Metal-Organic Framework) catalyst as well as preparation method and application thereof

A bimetallic and catalyst technology, applied in the field of material and chemical process research, can solve the problems of long reaction cycle, increased equipment investment cost, high reaction temperature, etc., to reduce cumbersome procedures and energy consumption, improve reaction safety performance, selectivity and The effect of high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The preparation method of Ce-Cu-MOF-1: the molar ratio of cerium nitrate hexahydrate and copper nitrate trihydrate is 1:6, the molar ratio of the ligand tribenzoic acid to the total metal precursor is 0.2, solvent ethanol and deionized water (same volume) and the total metal precursor molar ratio is 0.1, mix the bimetallic precursor, ligand and solvent and stir at room temperature for 30min; transfer it to the reactor and react at 80°C for 12h; after the reaction, The samples were filtered, washed and dried for later use.

[0035] The Ce-Cu-MOF-1 prepared in this example is a three-dimensional cage structure with a specific surface area of 682 cm 2 / g, the pore volume is 0.35cm 3 / g, the average pore size is 2.03nm; its structure schematic diagram is as follows figure 1 As shown, the element Ce replaces part of the element Cu to form a bimetallic MOF material.

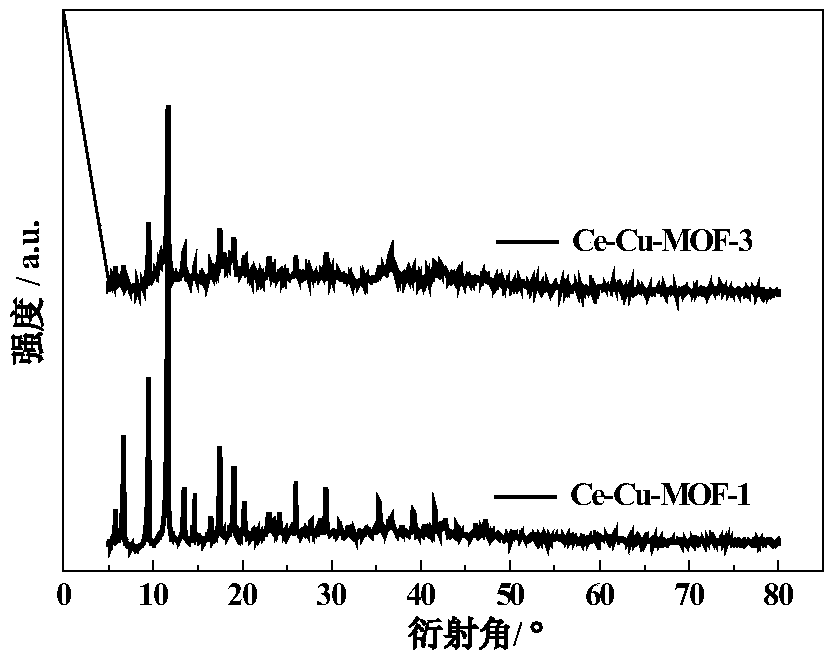

[0036] The XRD diffraction pattern of the bimetallic MOF material prepared in this example is shown in ...

Embodiment 2

[0039] The preparation method of Ce-Cu-MOF-2: the molar ratio of cerium nitrate hexahydrate and copper nitrate trihydrate is 6:1, the molar ratio of ligand trimesic acid to total metal precursor is 2.0, solvent ethanol and deionized water (same volume) to the total metal precursor molar ratio is 1.4, the bimetallic precursor, without stirring at room temperature, is directly transferred to the reactor and reacted at 100 ° C for 24 hours; after the reaction, the sample is filtered, washed, Dry and set aside.

[0040] The Ce-Cu-MOF-2 prepared in this example is a three-dimensional cage structure with a specific surface area of 176 cm 2 / g, the pore volume is 0.18cm 3 / g, the average pore diameter is 3.65nm.

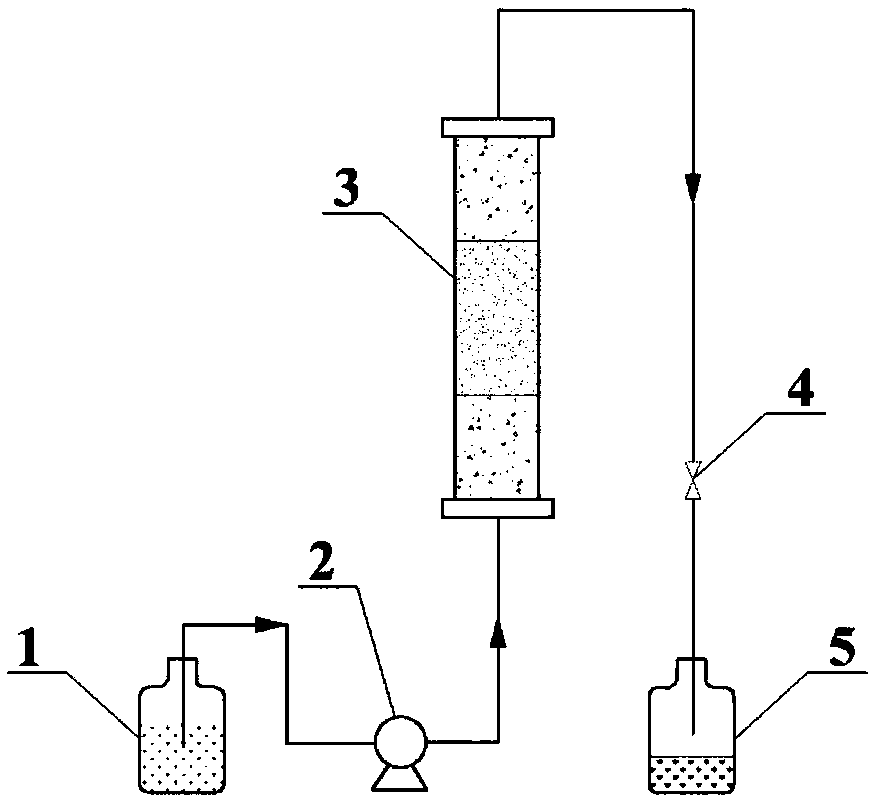

[0041] The synthesized Ce-Cu-MOF-2 was used as a catalyst in the fixed-bed reaction of catalytic oxidation of p-diethylbenzene to p-ethylacetophenone. The reaction conditions are that the purity of the p-diethylbenzene raw material is 90wt%, and the volumetric space ve...

Embodiment 3

[0043] The preparation method of Ce-Cu-MOF-3: the molar ratio of cerium nitrate hexahydrate and copper nitrate trihydrate is 2:5, the molar ratio of ligand trimesic acid to total metal precursor is 0.2, solvent ethanol and deionized water (same volume) and the total metal precursor molar ratio is 0.8, mix the bimetallic precursor, ligand and solvent and stir at room temperature for 30min; transfer it to the reactor and react at 100°C for 24h; after the reaction, The samples were filtered, washed and dried for later use.

[0044] The Ce-Cu-MOF-3 prepared in this example is a three-dimensional cage structure with a specific surface area of 462 cm 2 / g, the pore volume is 0.27cm 3 / g, the average pore diameter is 2.86nm.

[0045] The XRD diffraction pattern of the bimetallic MOF material prepared in this example is shown in figure 2 Ce-Cu-MOF-3 in.

[0046] The synthesized Ce-Cu-MOF-3 was used as a catalyst in the fixed-bed reaction of catalytic oxidation of p-diethylbenze...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com