A kind of preparation process of inducing negative ion surface glaze, ceramic tile and ceramic tile

A preparation process and negative ion technology, which is applied in the field of architectural ceramics, can solve problems such as inability to apply and affect the color development of brick surfaces, and achieve the effect of energetic, simple and easy-to-control preparation process steps, and indoor air purification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] A kind of preparation technology that can induce negative ion ceramic tile, comprises the following steps:

[0044] Preparation of surface glaze slurry: mix the raw materials that can induce negative ion surface glaze into the ball mill according to the ratio and perform wet ball milling to obtain surface glaze slurry;

[0045] Preparation of adobe: use existing adobe raw materials to make adobe;

[0046] Glazing: Apply glaze slurry on the surface of the brick;

[0047] It is fired in a kiln at a firing temperature of 1080-1200°C.

[0048] The conventional firing temperature can be used to complete the firing by using the existing firing temperature control, which is easier for process control. The preparation process steps of the ceramic tile capable of inducing negative ions are simple and easy to control.

[0049] Preferably, it also includes a surface decoration step: setting a decorative layer on the brick adobe with the glaze slurry by means of inkjet penetrati...

Embodiment 1

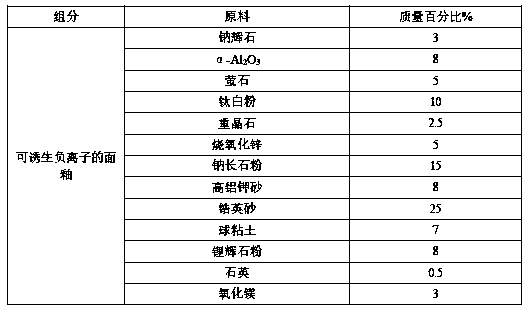

[0061] A kind of surface glaze that can induce negative ions, the raw material formula in terms of mass percentage is shown in the following table:

[0062]

[0063] The firing temperature of the above-mentioned top glaze is 1080-1100°C.

[0064] Ceramic tiles with the above-mentioned top glaze that can induce negative ions include a green body, a bottom glaze layer and a top glaze layer that are sequentially arranged from bottom to top. form. A decorative layer is arranged on the glaze layer by means of inkjet penetration process, inkjet printing, roller printing and / or screen printing.

[0065] The above-mentioned preparation technology that can induce negative ion ceramic tile comprises the following steps:

[0066] Prepare the surface glaze: Mix the raw materials of the surface glaze into the ball mill according to the proportion and perform ball milling to obtain the surface glaze slurry. The fineness of the surface glaze slurry is: 325 mesh sieve remaining 0.8~1.2, ...

Embodiment 2

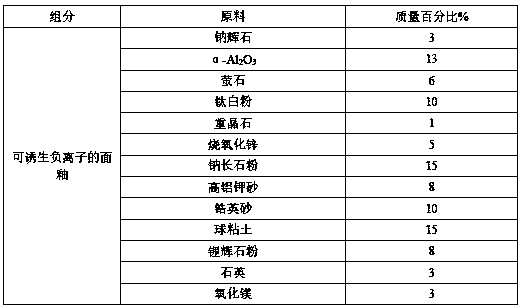

[0072] The anion-inducing surface glaze of the present embodiment, the tiles of the above-mentioned inducing anion-inducing surface glaze, and the preparation process of inducing anion-inducing ceramic tiles are basically the same as in Example 1, the difference is that the anion-inducing surface glaze can be induced to The raw material formula of mass percent meter is as shown in the table below:

[0073]

[0074] The firing temperature for inducing negative ion glaze is 1080-1150°C. The firing temperature of ceramic tiles that can induce negative ions is 1080-1150°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com