Room-temperature A-site doping method for APbX3 perovskite quantum dots

A quantum dot and perovskite technology, applied in the field of A-site doping method at room temperature, can solve the problems of poor quality of quantum dots, difficult high-performance light-emitting devices, and no effective improvement, and achieve the effect of improving device performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

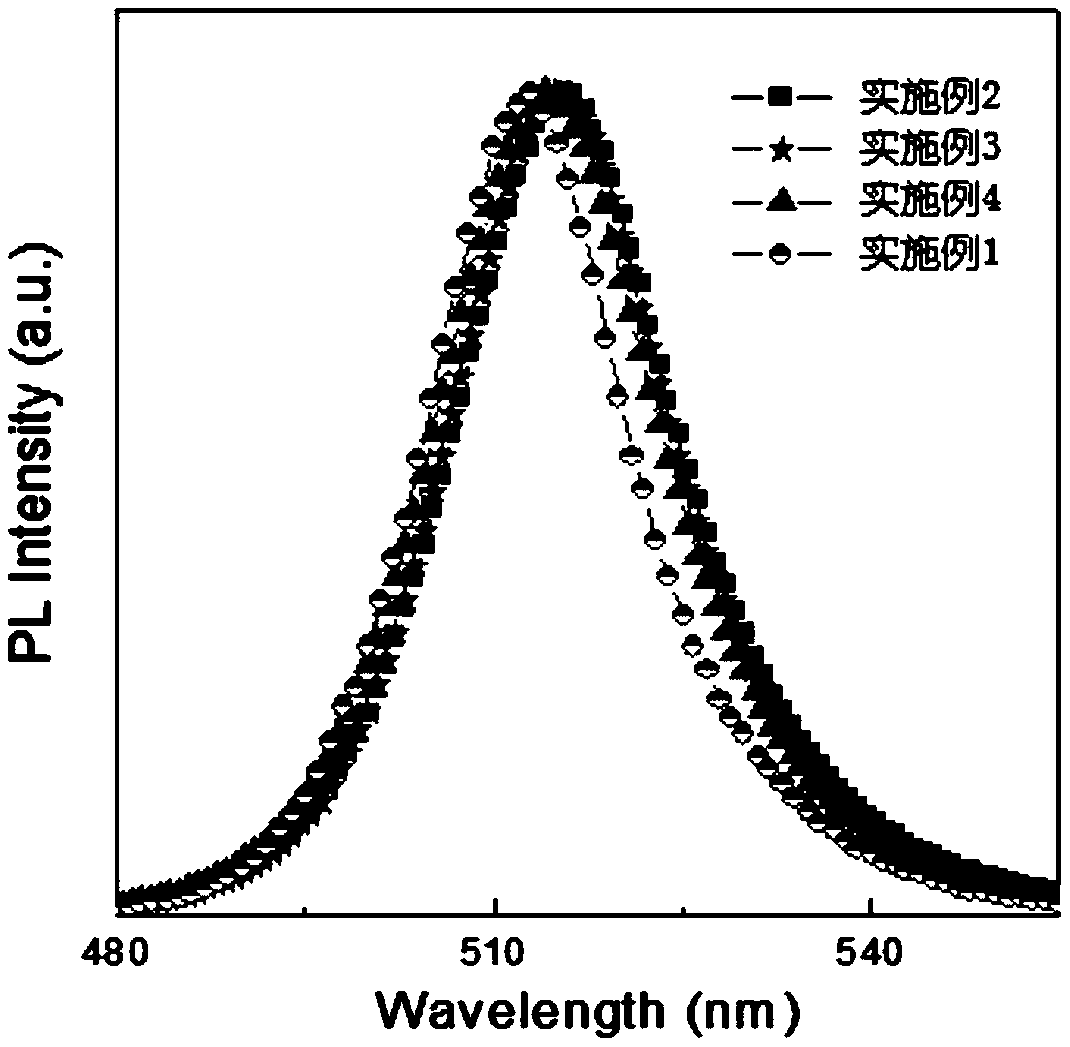

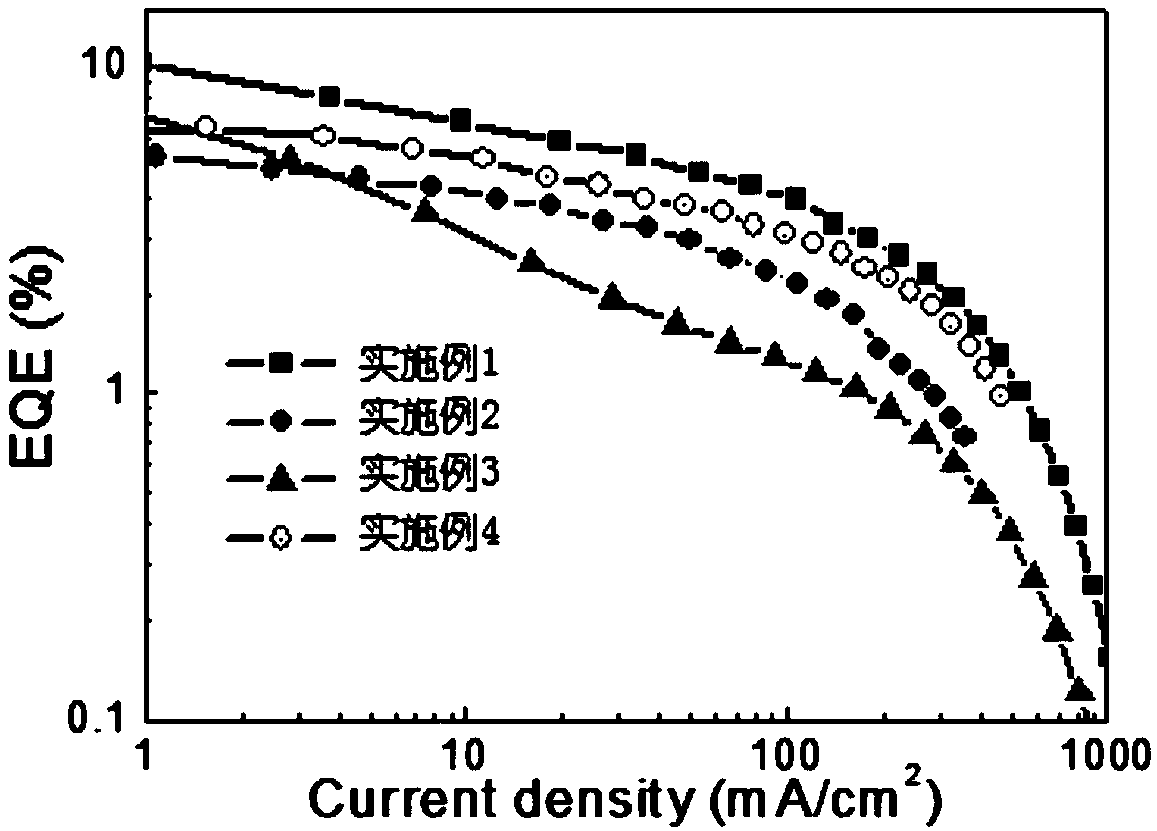

[0026] 1), 1 mmol of lead bromide and 2.2 mmol of tetraoctyl ammonium bromide were dissolved in 31 mL of toluene, and stirred in air at room temperature until completely dissolved to obtain a lead precursor;

[0027] 2) Dissolving 0.3mmol of cesium carbonate and 0.045mmol of formamidine acetate in 3mL of oleic acid to form a Cs+15% FA doped A-site precursor; FA is formamidine;

[0028] 3), inject the Cs+15%FA precursor into the lead precursor, react for 5min, and obtain (Cs 0.75 FA 0.15 )PbBr 3 Quantum dot stock solution;

[0029] 4), the quantum dot stock solution obtained above is purified by centrifugation to obtain (Cs 0.75 FA 0.15 )PbBr 3 quantum dots.

[0030] Application: Spin-coat PEDOT:PSS, Poly-TPD and (Cs 0.75 FA 0.15 )PbBr 3 Quantum dots, and then sequentially evaporate TPBi, LiF and Al electrodes in a thermal evaporation chamber to obtain a QLED device.

Embodiment 2

[0032] Using the same process as in Example 1, the difference is that the amount of formamidine acetate in step 2) of Example 1 is changed to 0, and other conditions remain the same to obtain undoped CsPbBr 3 QDs.

Embodiment 3

[0034] Using the same process as in Example 1, the difference is that the amount of formamidine acetate in step 2) of Example 1 is changed to 0.0225mmol, and other conditions remain the same to obtain FA doping concentration of 7.5% (Cs 0.75 FA 0.15 )PbBr 3 QDs.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com