Preparation method of high-reinforcing titanium dioxide for water-based coating

A technology of titanium dioxide and water-based coatings, applied in chemical instruments and methods, coatings, fibrous fillers, etc., can solve the problems of increasing the dispersion and compatibility of water-based coatings, poor weather resistance, easy cracking, etc., to improve water solubility, Good compatibility and enhanced binding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

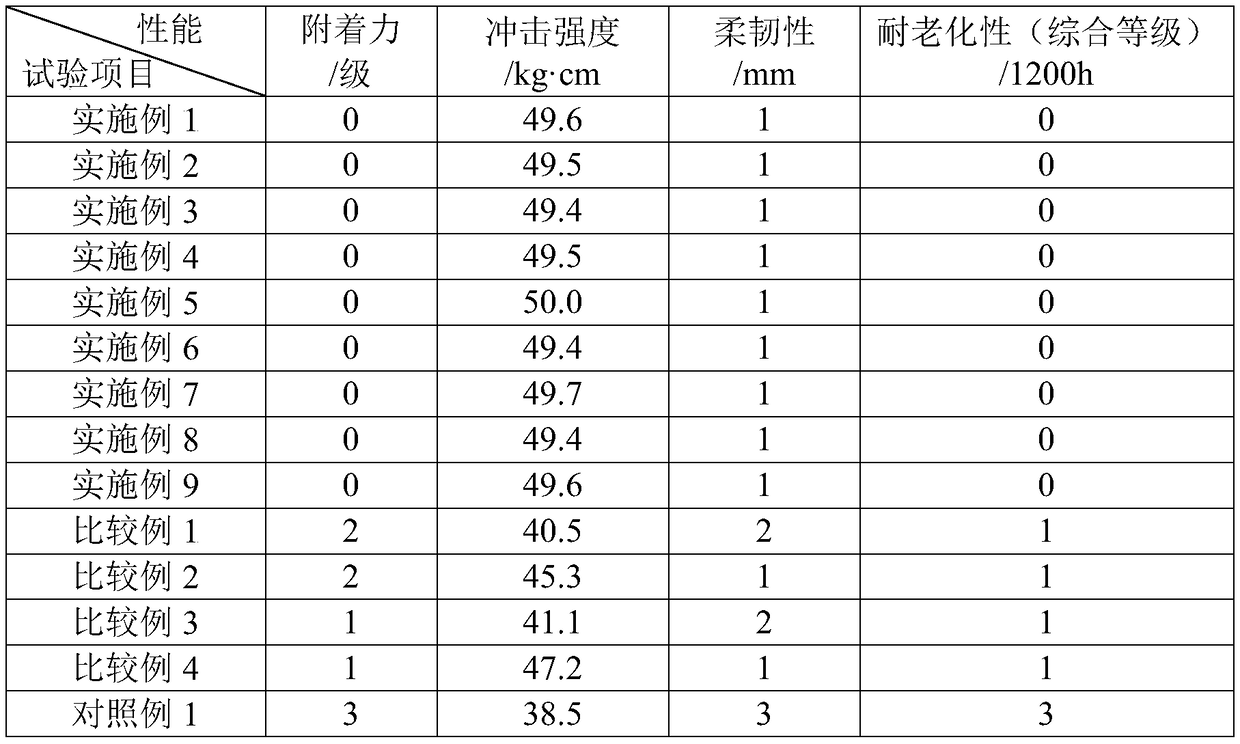

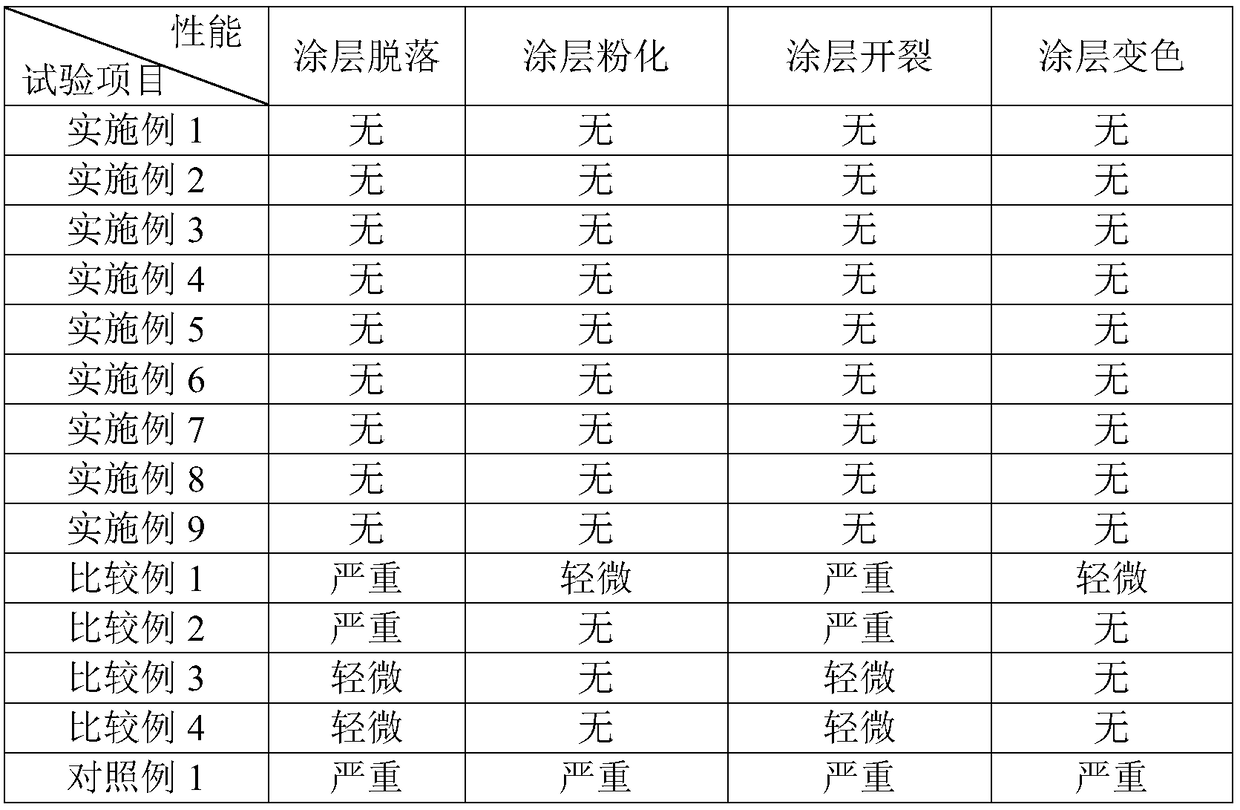

Examples

Embodiment 1

[0024] A kind of preparation that is used for the high reinforcement titanium dioxide of waterborne coating, its method step comprises:

[0025] A. Slurry preparation

[0026] Mix titanium dioxide and inorganic mineral powder in distilled water at a mass ratio of 30:1, then add a dispersant, the amount of dispersant added is 0.2% of the mass of titanium dioxide, and then stir at a speed of 200rpm for 10min to obtain a concentration of 300g / L Inorganic mineral powder and titanium dioxide mixed slurry; Wherein, the mass ratio of dispersant isopropanolamine and sodium silicate is 1:1;

[0027] B. Preparation of slurry

[0028] Add a pore-forming agent to the mixed slurry in step A, the addition amount is 8% of the mass of titanium dioxide, and then stir at a high speed of 2000rpm for 10min to obtain a slurry; wherein the pore-forming agent is urea and urea with a mass ratio of 1:1 ammonium carbonate;

[0029] C. Spray drying and pore making

[0030] The slurry prepared in ste...

Embodiment 2

[0034] A kind of preparation that is used for the high reinforcement titanium dioxide of waterborne coating, its method step comprises:

[0035] A. Slurry preparation

[0036] Mix titanium dioxide and inorganic mineral powder in distilled water at a mass ratio of 35:1, then add a dispersant in an amount of 0.3% of the mass of titanium dioxide, and then stir at a speed of 250rpm for 15min to obtain a concentration of 350g The mixed slurry of inorganic mineral powder and titanium dioxide in / L; Wherein, the mass ratio of dispersant isopropanolamine and sodium silicate is 1:2;

[0037] B. High speed stirring slurry

[0038] Add a pore-forming agent to the slurry in step A in an amount of 8% of the mass of titanium dioxide, and then stir at a high speed of 2000rpm for 10 minutes to obtain a slurry; wherein the pore-forming agent is urea and carbonic acid with a mass ratio of 1:2 Ammonium;

[0039] C. Spray drying and pore making

[0040] The slurry prepared in step B is used at ...

Embodiment 3

[0044] A kind of preparation that is used for the high reinforcement titanium dioxide of waterborne coating, its method step comprises:

[0045] A. Slurry preparation

[0046] Mix titanium dioxide and inorganic mineral powder in distilled water at a mass ratio of 40:1, then add a dispersant in an amount of 0.4% of the mass of titanium dioxide, and then stir at a speed of 300rpm for 20min to obtain a concentration of 400g The mixed slurry of inorganic mineral powder and titanium dioxide in / L; Wherein, dispersant is the isopropanolamine and sodium silicate that mass ratio is 1:1.5;

[0047] B. Preparation of slurry

[0048] Add the slurry in step A to a pore-forming agent in an amount of 8% of the mass of titanium dioxide, and then stir at a high speed of 2100 rpm for 15 minutes to obtain a mixed slurry; wherein the pore-forming agent is a pore-forming agent with a mass ratio of 1:1.5 Urea and ammonium carbonate;

[0049] C. Spray drying and pore making

[0050] The mixed s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com