Aloe cultivation method for improving tensile properties of aloe fibers

A cultivation method and aloe fiber technology, applied in gardening methods, planting substrates, botanical equipment and methods, etc., can solve problems such as acceleration, unsatisfactory tensile properties of aloe fibers, affecting the utilization value of aloe fibers and the utilization efficiency of aloe resources , to achieve the effect of increasing the elongation at break in the dry state and the elongation at break in the wet state, inhibiting the phenomenon of soil hardening and compaction, and promoting the efficiency of absorption and transformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

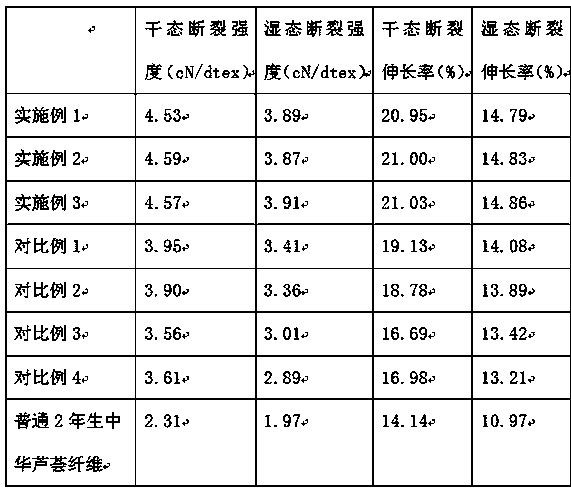

Examples

Embodiment 1

[0016] In the embodiment of the present invention, a method for cultivating aloe that improves the tensile properties of aloe fibers, the specific method is as follows:

[0017] Cutting the leaves of aloe vera into the culture medium, the cutting depth is 1.4~1.6cm, after cutting, use the blue light with the light intensity of 2300Lx to carry out supplementary light treatment every day at 22:40~2:50; start the root fermenting after 13~15 days of cutting Lemon lettuce leaf juice, and fermented lemon lettuce leaf juice every 13 to 15 days, and the amount of each root application is 200mL / plant;

[0018] The culture substrate is made of the following raw materials in parts by weight: 20 parts of grape pomace, 9 parts of activated vermiculite powder, 44 parts of garden soil, 4.1 parts of phoenix bark, 6.6 parts of peanut shells, 4.9 parts of cotton shells, fresh carrots 9 parts of tassels, 6.1 parts of fresh mulberry leaves, 0.09 parts of chrysin, 0.12 parts of genistein, 0.16 par...

Embodiment 2

[0025] In the embodiment of the present invention, a method for cultivating aloe that improves the tensile properties of aloe fibers, the specific method is as follows:

[0026] Cutting the leaves of aloe vera into the culture medium, the cutting depth is 1.4~1.6cm, after the cutting, use the blue light with the light intensity of 2400Lx to carry out the supplementary light treatment every day at 22:40~2:50; start the root fermentation after 13~15 days of cutting Lemon lettuce leaf juice, and fermented lemon lettuce leaf juice every 13 to 15 days, and the amount of each root application is 205mL / plant;

[0027] The culture substrate is made of the following raw materials in parts by weight: 21 parts of grape pomace, 9.5 parts of activated vermiculite powder, 46 parts of garden soil, 4.3 parts of sycamore bark, 6.9 parts of peanut shells, 5.1 parts of cotton shells, fresh carrots 9.5 parts of tassels, 6.3 parts of fresh mulberry leaves, 0.095 parts of chrysin, 0.125 parts of ge...

Embodiment 3

[0034] In the embodiment of the present invention, a method for cultivating aloe that improves the tensile properties of aloe fibers, the specific method is as follows:

[0035] Cutting the leaves of aloe vera into the culture medium, the cutting depth is 1.4~1.6cm, after cutting, use the blue light with the light intensity of 2500Lx to carry out supplementary light treatment every day at 22:40~2:50; start the root fermentation after 13~15 days of cutting Lemon lettuce leaf juice, and fermented lemon lettuce leaf juice every 13 to 15 days, and the amount of each root application is 210mL / plant;

[0036] The culture substrate is made of the following raw materials in parts by weight: 22 parts of grape pomace, 10 parts of activated vermiculite powder, 48 parts of garden soil, 4.5 parts of Chinese parasol bark, 7.2 parts of peanut shells, 5.3 parts of cotton shells, fresh carrot 10 parts of tassels, 6.5 parts of fresh mulberry leaves, 0.1 parts of chrysin, 0.13 parts of genistein...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com