Compound fertilizer specially used for tobacco and method for preparing compound fertilizer by adopting phosphorite flotation tailings

A technology for flotation tailings and compound fertilizers, which is applied in urea compound fertilizers, applications, nitrogen fertilizers, etc., can solve the problems of ineffective utilization of materials and occupation of land resources, avoid nutrient deficiency or local enrichment, improve structure, The effect of improving biological traits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

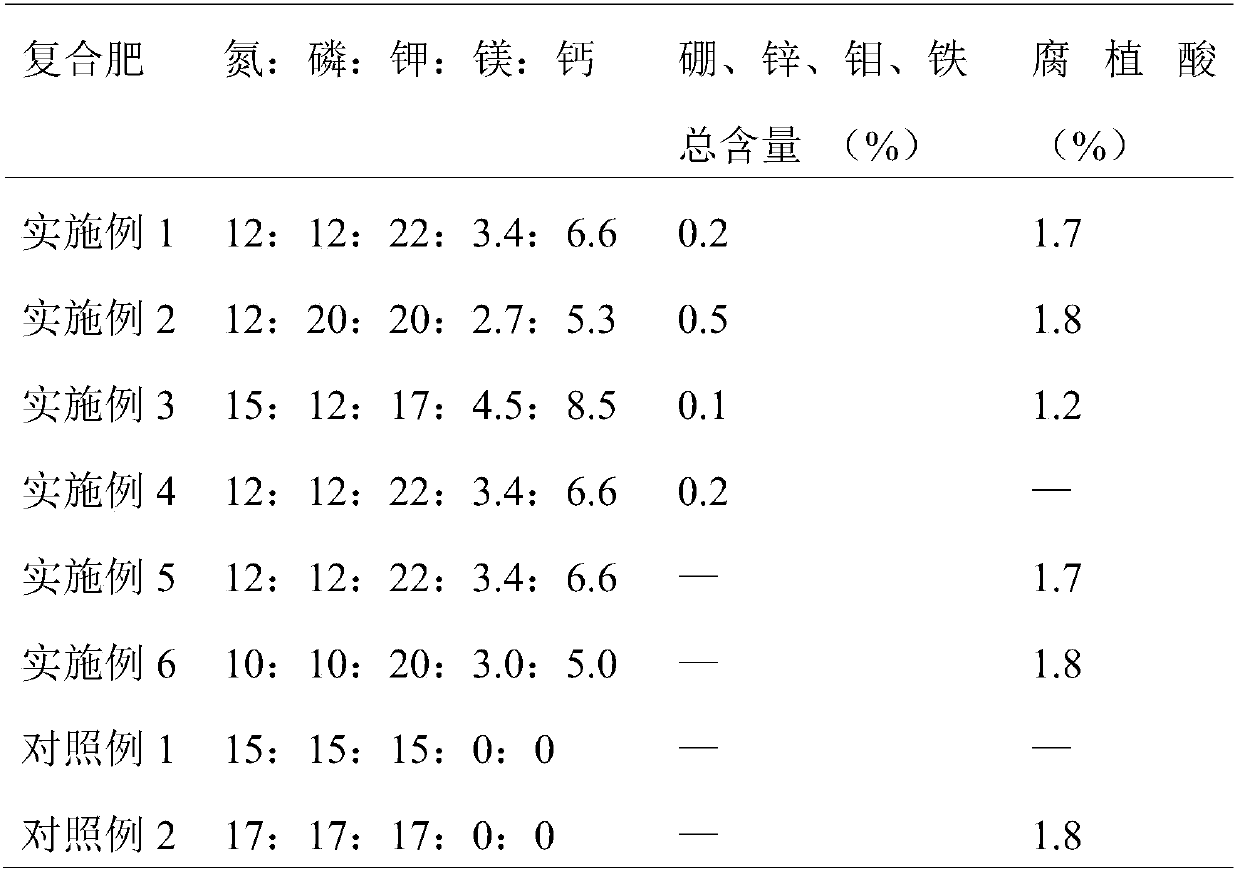

Examples

Embodiment 7

[0036] A kind of method that adopts phosphate ore flotation tailings to prepare above-mentioned special compound fertilizer for tobacco is prepared according to the following steps:

[0037]In parts by weight, add 200 parts of phosphate rock flotation tailings and 150 parts of water into the reactor, mix well and stir evenly, then add 150 parts of nitric acid with a concentration of 65% into the reactor, and stir for 5 minutes Filter and keep the filtrate; add 100 parts of monoammonium phosphate, 50 parts of ammonium nitrate, 50 parts of urea, 300 parts of potassium nitrate, 190 parts of potassium dihydrogen phosphate in the filtrate, and when it is fully dissolved, add 15 parts of humic acid, 2 Part of agricultural borax, 2 parts of zinc sulfate, 2 parts of ammonium heptamolybdate and 2 parts of ferrous sulfate, fully stirred and dissolved, and finally feed ammonia to adjust the pH value of the solution to 6.0-7.0 to obtain fertilizer slurry; Concentrate, spray and granulate,...

Embodiment 8

[0040] A kind of method that adopts phosphate ore flotation tailings to prepare above-mentioned tobacco-specific compound fertilizer, carries out according to the following steps:

[0041] In parts by weight, add 150 parts of phosphate rock flotation tailings and 200 parts of water into the reactor, mix well and stir evenly, then add 100 parts of nitric acid with a concentration of 65% into the reactor, react for 10 minutes and then filter , retain the filtrate; add 200 parts of monoammonium phosphate, 50 parts of ammonium nitrate, 50 parts of urea, 300 parts of potassium nitrate, 100 parts of potassium dihydrogen phosphate, and 100 parts of potassium sulfate in the filtrate, and after it is fully dissolved, add 15 parts of rotten Phenolic acid, 5 parts of agricultural borax, 5 parts of zinc sulfate, 5 parts of ammonium heptamolybdate and 5 parts of ferrous sulfate are fully stirred and dissolved, and finally feed ammonia to adjust the pH value of the solution to obtain fertili...

Embodiment 9

[0043] A kind of preparation method that adopts phosphate ore flotation tailings to prepare above-mentioned tobacco-specific compound fertilizer, carries out according to the following steps:

[0044] In parts by weight, add 250 parts of phosphate rock flotation tailings and 200 parts of water into the reactor, mix well and stir evenly, then add 200 parts of nitric acid with a concentration of 65% into the reactor, react for 10 minutes and then filter , retain the filtrate; add 100 parts of monoammonium phosphate, 70 parts of ammonium nitrate, 80 parts of urea, 300 parts of potassium nitrate, 90 parts of potassium dihydrogen phosphate in the filtrate, and wait for it to fully dissolve, then add 10 parts of humic acid, 1 part of Agricultural borax, 1 part of zinc sulfate, 1 part of ammonium heptamolybdate and 1 part of ferrous sulfate are fully stirred and dissolved, and finally ammonia gas is introduced to adjust the pH value of the solution to 6.0-7.0 to obtain fertilizer slur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com