Bubble floating ball and manufacturing process thereof

A manufacturing process and floating ball technology, applied in the field of chemical process, can solve the problems of white pollution of marine environment, limited service life, small size, etc., and achieve the effects of avoiding marine pollution, improving performance, and improving impact strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

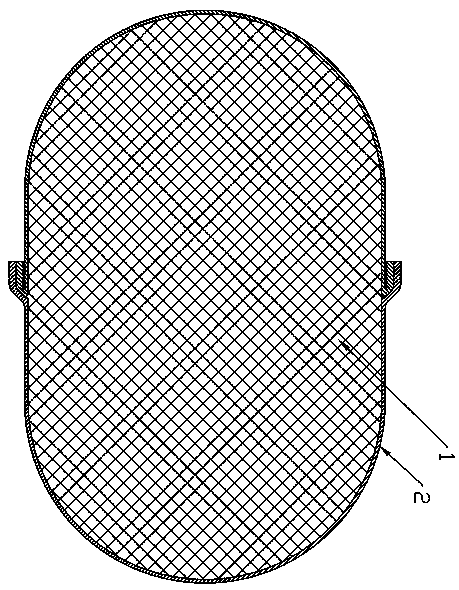

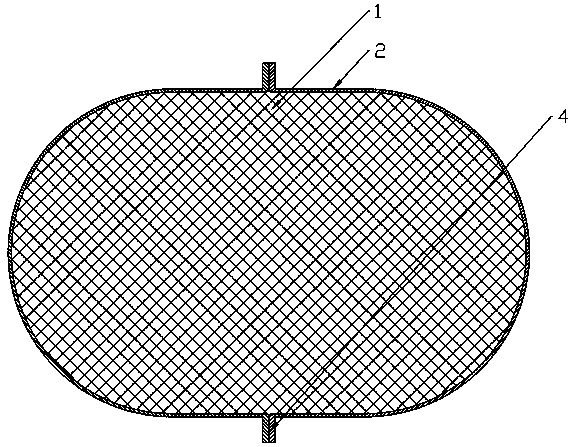

[0035] For marine mussel culture, take the commonly used foam float as an example. The appearance of the float is a cylindrical float with two arc-shaped ends, the diameter is Ф500mm, and the total length of the cylinder is 800mm. The shell coating thickness is preferably 0.8-1.0mm. The shell coating material is PS material, and the inner core is EPS foam material. The specific coating process includes the following steps:

[0036] 1. Material selection: PS raw material performance selects high-impact grade, grade selects extruded sheet grade, granular raw material.

[0037] 2. Sheet production: The PS raw material is made into a sheet through a sheet forming machine. The thickness of the sheet is 2-2.4 times the thickness after blistering, the width of the sheet is 1100mm, and the temperature of the extrusion molding die is 180-200°C.

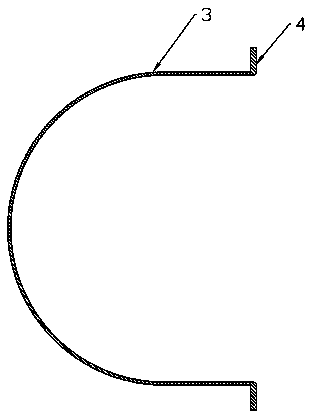

[0038] 3. Blistering: the sheet is made into two semi-elliptical or hemispherical shells 33 through a blister forming machine, the forming mo...

Embodiment 2

[0047] According to the situation of embodiment 1, the specification of the floating ball is reduced, the diameter is 300mm, the total length of the cylinder is 600mm, the thickness of the outer shell is also 0.5-0.6mm, the material of the outer shell is PVC and ABS blended plastic alloy, and the inner core For EPS foam materials, the specific coating process includes the following steps:

[0048] 1. Proportion by mass percentage: PVC64%, ABS20%, CaCo 3 10%, compound stabilizer 2%, dioctyl fat 3%, lubricant 0.5%, black carbon powder 0.05%-0.1%.

[0049] 2. The stirred mixture is made into a sheet through a twin-screw sheet forming machine. The thickness of the sheet is 2-2.4 times the thickness of the blister, the width of the sheet is 700mm, and the temperature of the extrusion die is 170-190°C.

[0050] The steps from 3 to 6 are the same as those in Implementation 1.

[0051] Test for the foam buoy made in embodiment two:

[0052] 1. Drop the foam float from the 10m three...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com