Z-type Ag3PO4/G/C3N4 (silver phosphate/graphene/carbon nitride) photocatalyst bridged by graphene (G) and preparation method thereof

A C3N4, photocatalyst technology, applied in physical/chemical process catalysts, chemical instruments and methods, oxygen/ozone/oxides/hydroxides, etc., to achieve mild reaction conditions, improved catalyst and stability, and simple and easy preparation methods line effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

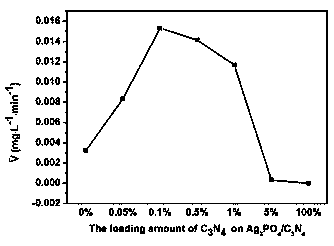

[0022] Embodiment 1, C 3 N 4

[0023] 0.3429g imidazole is dispersed in 5mL water, then 9.0110g urea is added in the above solution, 80 o C under heating and stirring for 30min, and then the sample was half-sealed and placed in a muffle furnace at 350 o C burning for 3h. After natural cooling, ground to obtain C 3 N 4 Pale yellow sample.

Embodiment 2

[0024] Example 2, Ag 3 PO 4

[0025] 0.8075g AgNO 3 Dispersed into 20mL water, 0.7453g NaH 2 PO 4 Disperse in 10mL of water, NaH 2 PO 4 The aqueous solution was added dropwise to the AgNO 3 in aqueous solution, centrifuged after stirring for 2h, 70 o Dry at C for 12h and grind to get Ag 3 PO 4 Yellow sample.

Embodiment 3

[0026] Example 3, Ag 3 PO 4 / C 3 N 4 -0.05wt%

[0027] 0.0005g of C 3 N 4 and 1.2704g AgNO 3 Disperse in 30mL of water, stir for 30min, and then ultrasonically disperse for 100min. 0.3900g NaH 2 PO 4 Disperse in 20mL of water, NaH 2 PO 4 The aqueous solution was added dropwise to the above suspension, and stirred for 2h. centrifugation, 70 o C dried for 12h, and ground to obtain a sample.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com