Volume-phase hydroprocessing catalyst and preparation method thereof

A catalyst and hydrogen treatment technology, which is applied in the field of distillate oil hydrogenation, can solve the problems of difficult control of the distribution of hydrogenation active metals, reduce the interaction of active metals, and the small content of active metals in the surface phase, so as to achieve the utilization rate of hydrogenation active metals And the effect of high internal utilization rate of catalyst, reduction of deactivation rate, and reduction of production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

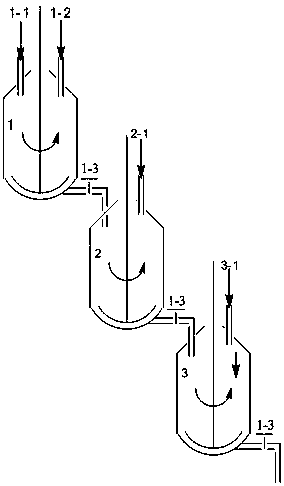

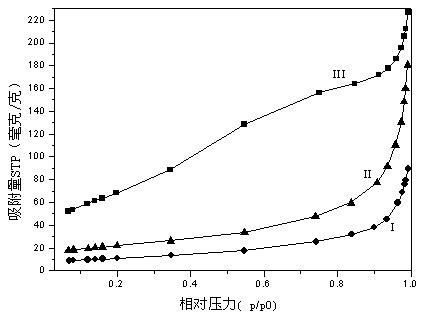

Method used

Image

Examples

Embodiment 1

[0057] This example introduces the preparation method of Mo and Ni original solutions. In this example, only one original solution of Mo and Ni was prepared with one concentration and ratio, and solutions with other ratios and concentrations can be prepared according to the method introduced.

[0058] Take 386g of molybdenum oxide and 123g of basic nickel carbonate into a multi-necked flask, add a certain amount of deionized water, stir until the substance in the bottle is slurry, then slowly add 86g of phosphoric acid, and then heat slowly after the initial reaction , keep the solution temperature at 90-110°C for 1-3 hours, stop heating, filter the obtained solution while it is hot, and then add phosphoric acid to adjust the pH value of the solution to 1.0-4.0 to obtain a clear dark green original solution. The solution composition is MoO 3 : 69.27g / 100ml; NiO: 12.49g / 100ml.

[0059] Get 296g ammonium molybdate, 105g nickel nitrate is put into multi-necked flask, after addi...

Embodiment 2

[0061] Dimethylammonium chloride 300g, ammonium tetrafluoroborate 190g, pure water 450g, mixed, heated to 80°C under stirring, kept at constant temperature for 1 hour, clarified, naturally cooled to about 30°C, centrifuged to filter out the solid to obtain 300g of ionic liquid I , the water content is about 3.5wt%, and the yield is 73wt%.

[0062] 400g of triethylammonium chloride, 220g of sodium hexafluorophosphate, and 450g of pure water were mixed, heated to 90°C under stirring, kept at a constant temperature for 3 hours, clarified, naturally cooled to about 30°C, and centrifuged to filter out the solid to obtain 450g of ionic liquid II. The water content is about 3.5wt%, and the yield is 72wt%.

[0063] Propyl tri-n-butyl ammonium chloride 600g, sodium hexafluorophosphate 360g, pure water 550g, mix, heat to 90°C under stirring, keep the temperature for 3 hours, clarify, naturally cool to about 30°C, centrifuge to filter out the solid to obtain ions Liquid III was 750g, co...

Embodiment 3

[0067] Diethylammonium chloride 250g, ammonium tetrafluoroborate 180g, pure water 400g, mixed, heated to 90°C under stirring, kept at constant temperature for 1.5h, clarified, naturally cooled to about 30°C, centrifuged to filter out the solid to obtain ionic liquid I 260g, water content about 3.5wt%, yield 73wt%.

[0068] Triethylammonium chloride 300g, sodium hexafluorophosphate 160g, pure water 350g, mixed, heated to 100°C under stirring, kept at constant temperature for 2.5h, clarified, naturally cooled to about 30°C, centrifuged to filter out the solid to obtain 420g of ionic liquid II , the water content is about 3.7wt%, and the yield is 72wt%.

[0069] Dipropyldi-n-butylammonium chloride 400g, sodium hexafluorophosphate 340g, pure water 600g, mix, heat to 90°C under stirring, keep the temperature for 3 hours, clarify, naturally cool to about 30°C, centrifuge and filter out the solid to obtain The ionic liquid III was 710g, the water content was about 3.8wt%, and the yi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com