A method for synthesizing core-shell structure carbon-coated gold nanoparticles with regular spherical morphology

A technology of core-shell structure and nanoparticles, which is applied in nanotechnology, transportation and packaging, metal processing equipment, etc., and can solve the problems of strong physical and chemical inertness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

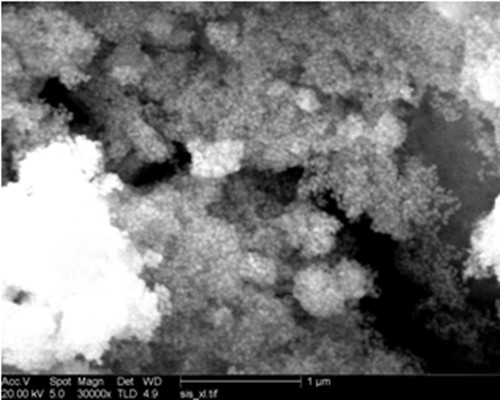

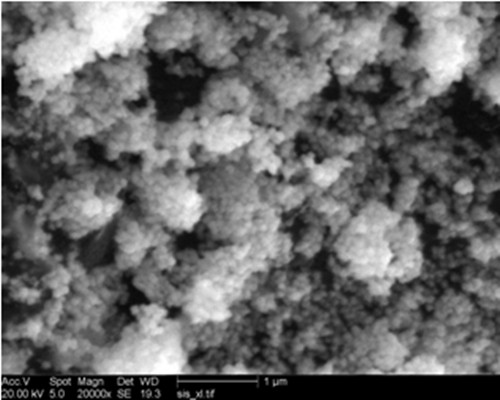

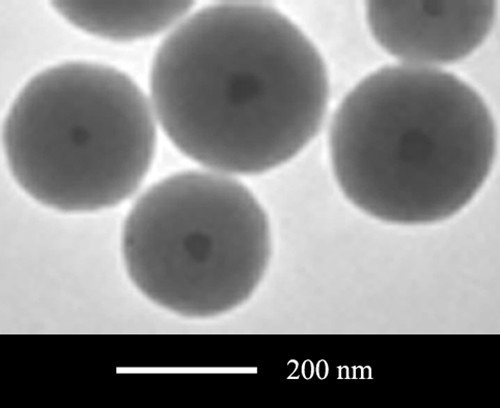

Image

Examples

specific Embodiment approach 1

[0014] Specific embodiment 1: In this embodiment, a method for synthesizing core-shell structure carbon-coated gold nanoparticles with regular spherical morphology is realized according to the following steps:

[0015] 1. Preparation of nano-gold particles: HAuCl4 and sodium borohydride with a molar ratio of 1:0.2-0.5 were dissolved in water, and stirred at room temperature for 10-25 minutes to obtain a nano-gold particle solution.

[0016] 2. Add a hydroquinone (resorcinol) solution with a molar ratio of 1 to 50 to HAuCl4 to the gold nanoparticle solution prepared in step 1, stir at room temperature for 10 to 25 minutes, and then add a solution with a molar ratio of 2 to HAuCl4. 100% formaldehyde solution (formaldehyde solution with a mass fraction of 37%), stirred at room temperature for 10-25min, then added absolute ethanol with a molar ratio of 500-700 to HAuCl4, stirred at room temperature for 10-25min, then added dropwise with HAuCl4 molar ratio of 5~10, ammonia solution...

specific Embodiment approach 2

[0019] Embodiment 2: This embodiment differs from Embodiment 1 in that the molar ratio of resorcinol to HAuCl4 added in step 2 is 10-50:1. Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0020] Embodiment 3: This embodiment is different from Embodiment 2 in that the molar ratio of resorcinol to HAuCl4 added in step 2 is 25-50:1. Other steps and parameters are the same as in the second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com