A method for synthesizing all-silicon micro-mesoporous composites

A mesoporous and silicon-micro technology, applied in the field of all-silicon micro-mesoporous composite materials and their synthesis, to achieve the effects of increasing production, increasing solid content, and saving raw material costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

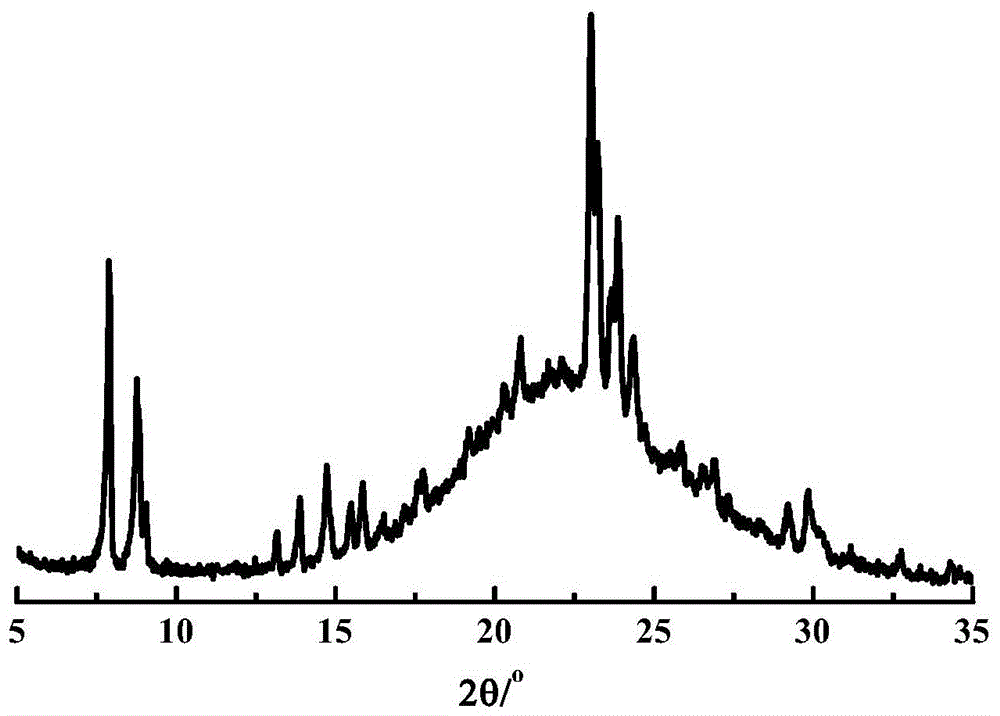

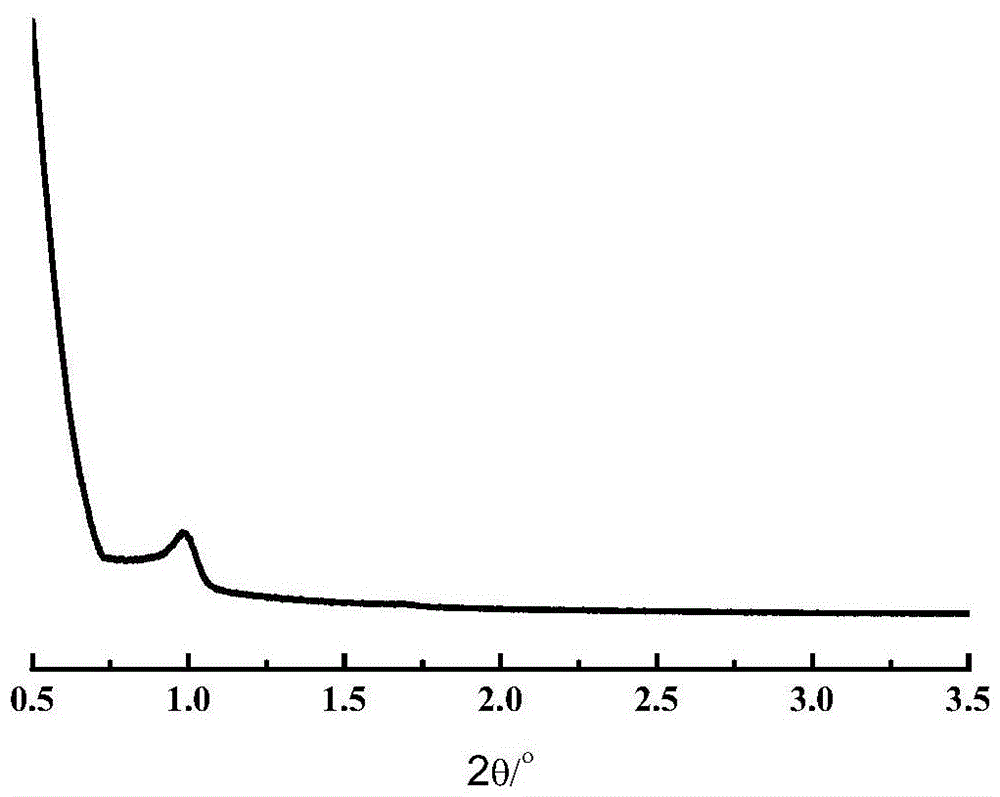

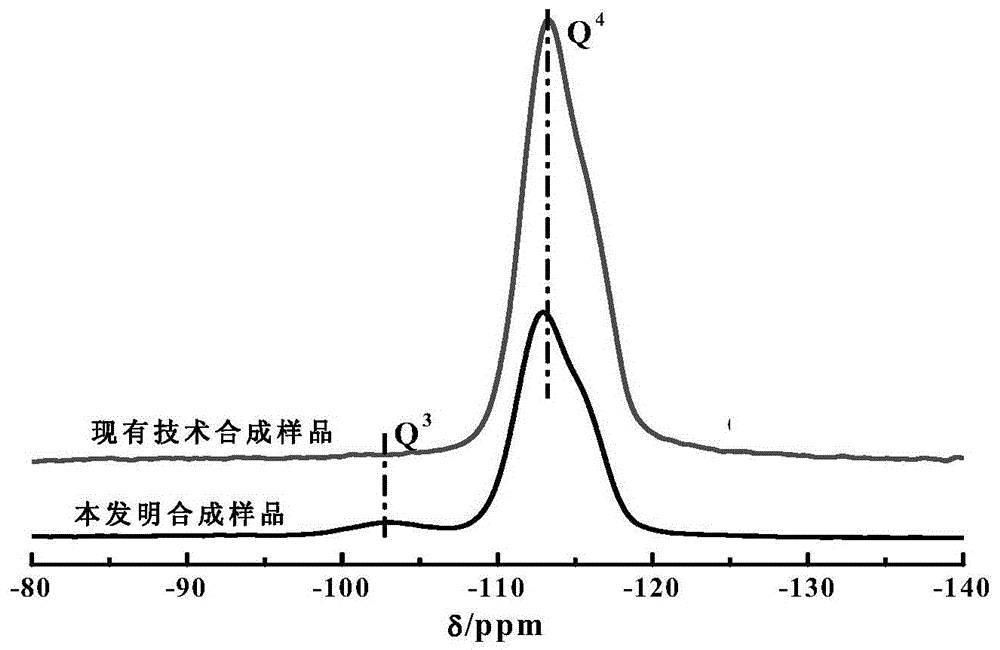

[0027] In one embodiment, the all-silicon micro-mesoporous composite molecular sieve has an MFI structure, and the organic quaternary ammonium compound includes or is tetrapropylammonium hydroxide, tetrapropylammonium chloride, tetrapropylammonium bromide one or more of . Wherein the molar ratio of one or more of tetrapropylammonium hydroxide, tetrapropylammonium chloride, and tetrapropylammonium bromide to the silicon source is preferably not less than 0.01:1, such as 0.02 to 0.2:1 , or 0.04~0.15:1.

[0028] In one embodiment, the all-silicon micro-mesoporous composite molecular sieve has a MEL structure, and the organic quaternary ammonium compound includes or is one of tetrabutylammonium hydroxide, tetrabutylammonium bromide, and tetrabutylammonium chloride. one or more species. Wherein the molar ratio of one or more of tetrabutylammonium hydroxide, tetrabutylammonium bromide, and tetrabutylammonium chloride to the silicon source is preferably not less than 0.01:1, such a...

Embodiment 1

[0056] (1) Mix 12.1g of tetrapropylammonium hydroxide aqueous solution with a concentration of 25.05% by weight, 0.8g of tetrapropylammonium bromide solid, 20.8g of tetraethyl silicate, 2g of ethylenediamine, 13.14g of cetyltri Methyl ammonium bromide, 0.26g concentration of 20% by weight of ammonia and 120g deionized water were added to a 500ml beaker successively, put into a magnetic stirrer with heating and stirring functions, and stirred at 80°C for 4 hours. Supplement the evaporated water to obtain the organic alkali hydrolyzate of silicon; wherein the content of monohydric alcohol does not exceed 10ppm;

[0057] (2) cooling the obtained silicon organic alkali hydrolyzate to room temperature under stirring, and then standing at room temperature for 12 hours for aging to obtain an aged product;

[0058] (3) Under stirring, add 12g of white carbon black powder to the aging product, stir for 1 hour, transfer it to a closed stainless steel reaction kettle, and crystallize at ...

Embodiment 2~4

[0062] The molecular sieve was prepared according to the method of Example 1, except that the ratio and preparation conditions were adjusted, wherein the conditions of step (4) were unchanged, the preparation conditions were shown in Table 1, and the characterization results of the obtained molecular sieve were shown in Table 2. The resulting molecular sieve has an MFI structure.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| micropore | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com