A preparation method of silica@noble metal nanocomposite microspheres

A silicon dioxide and nanocomposite technology, applied in the direction of microsphere preparation, microcapsule preparation, etc., can solve the problems of high consumption of organic solvents, non-compliance with environmental protection requirements, high requirements for reaction devices, etc., to achieve adjustable particle size, particle size Uniform and reproducible results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

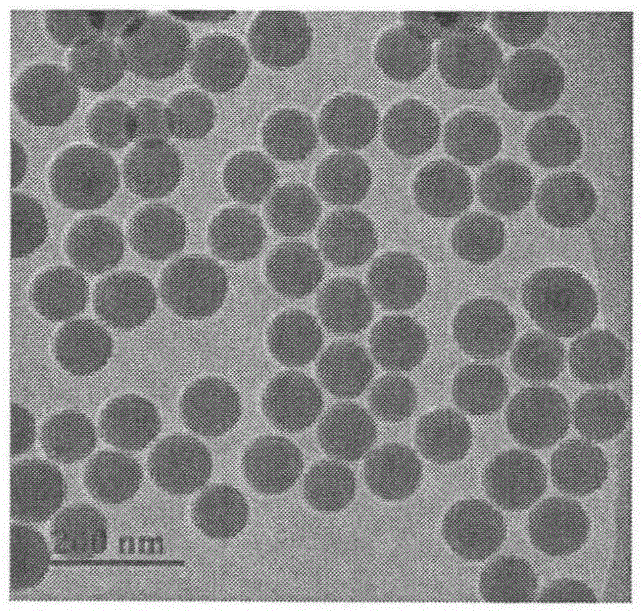

[0024] Put 59.20mL triple-distilled water, 38.00mL absolute ethanol, and 2.80mL concentrated ammonia water into a 250mL three-necked flask in sequence, and stir magnetically at 1100rpm for 30min. After mixing evenly, quickly pour the uniform mixed solution of 9.00mLTEOS and 91.00mL absolute ethanol into the above-mentioned three-neck flask. After 2min, reduce the stirring speed to 400rpm, keep the reaction at 25°C for 6h, centrifuge at 10000rpm for 5min, and use anhydrous Washed several times with ethanol and triple distilled water to obtain monodisperse SiO 2 nanospheres, which are then dispersed in water, SiO 2 The mass fraction is 2mg / ml. Transmission electron microscope observation shows that the SiO obtained by the reaction 2 Nanoparticles are spherical, about 100 nm in diameter, and monodisperse, such as figure 1 shown.

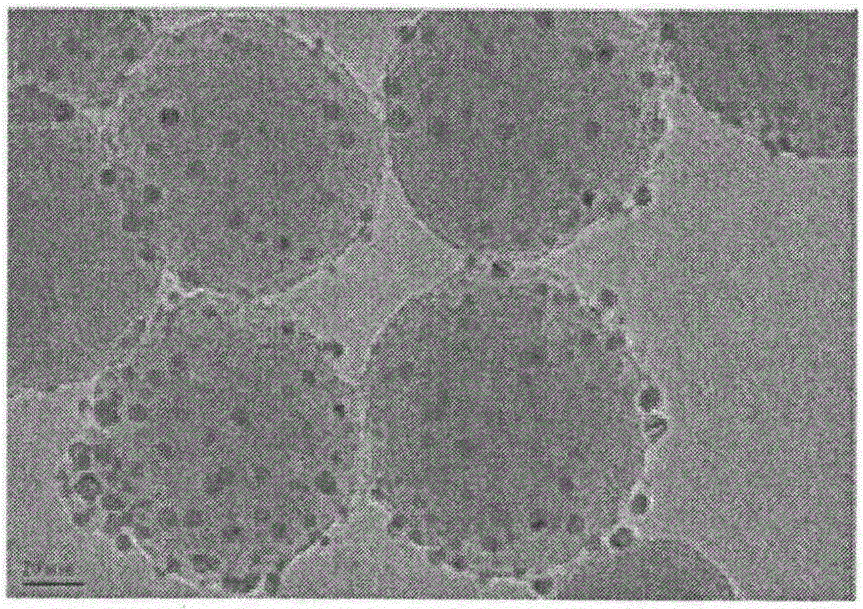

[0025]Add 5mL 2mg / mL PAH aqueous solution (NaCl 0.5M pH 5~6) to 50mL SiO 2 In the dispersion, after ultrasonication at room temperature for 60 min...

Embodiment 2

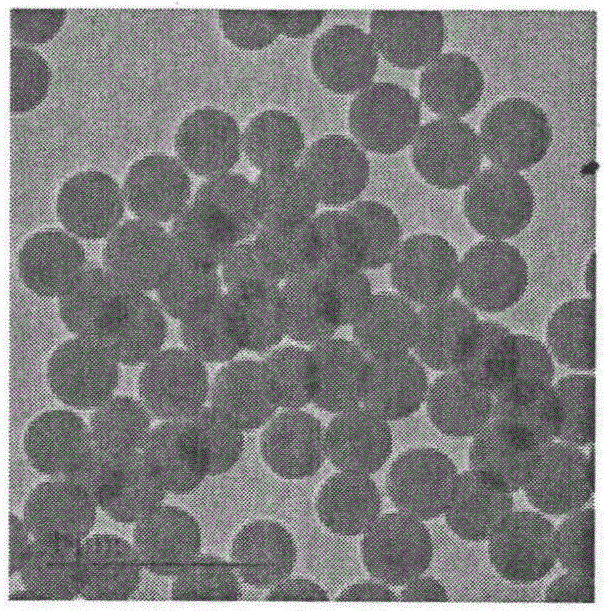

[0027] Put 55.10 mL triple-distilled water, 36.50 mL absolute ethanol, and 8.40 mL concentrated ammonia water into a 250 mL three-necked flask in sequence, and stir magnetically at 1100 rpm for 30 min. After mixing evenly, quickly pour the uniform mixed solution of 9.00mLTEOS and 91.00mL absolute ethanol into the above-mentioned three-neck flask. After 2min, reduce the stirring speed to 400rpm, keep the reaction at 25°C for 6h, centrifuge at 10000rpm for 5min, and use anhydrous Washed several times with ethanol and triple distilled water to obtain monodisperse SiO 2 nanospheres, which are then dispersed in water, SiO 2 The mass fraction is 2mg / ml. Transmission electron microscope observation shows that the SiO obtained by the reaction 2 Nanoparticles are spherical, about 300 nm in diameter, and monodisperse, such as image 3 shown.

[0028] Add 5 mL of 2 mg / mL PAH aqueous solution (NaCl 0.5M pH 5-6) to 50 mL of SiO 2 In the dispersion, after ultrasonication at room temper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com