Method and device for continuous preparing of high-silicon silicon steel thin strip

A thin strip, silicon steel technology, applied in electrolytic coatings, coatings, electrolytic processes, etc., can solve the problems of high external magnetic field strength, poor surface quality of silicon steel, rough coating morphology, etc., achieve large contact area, save energy, avoid Difficulty processing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

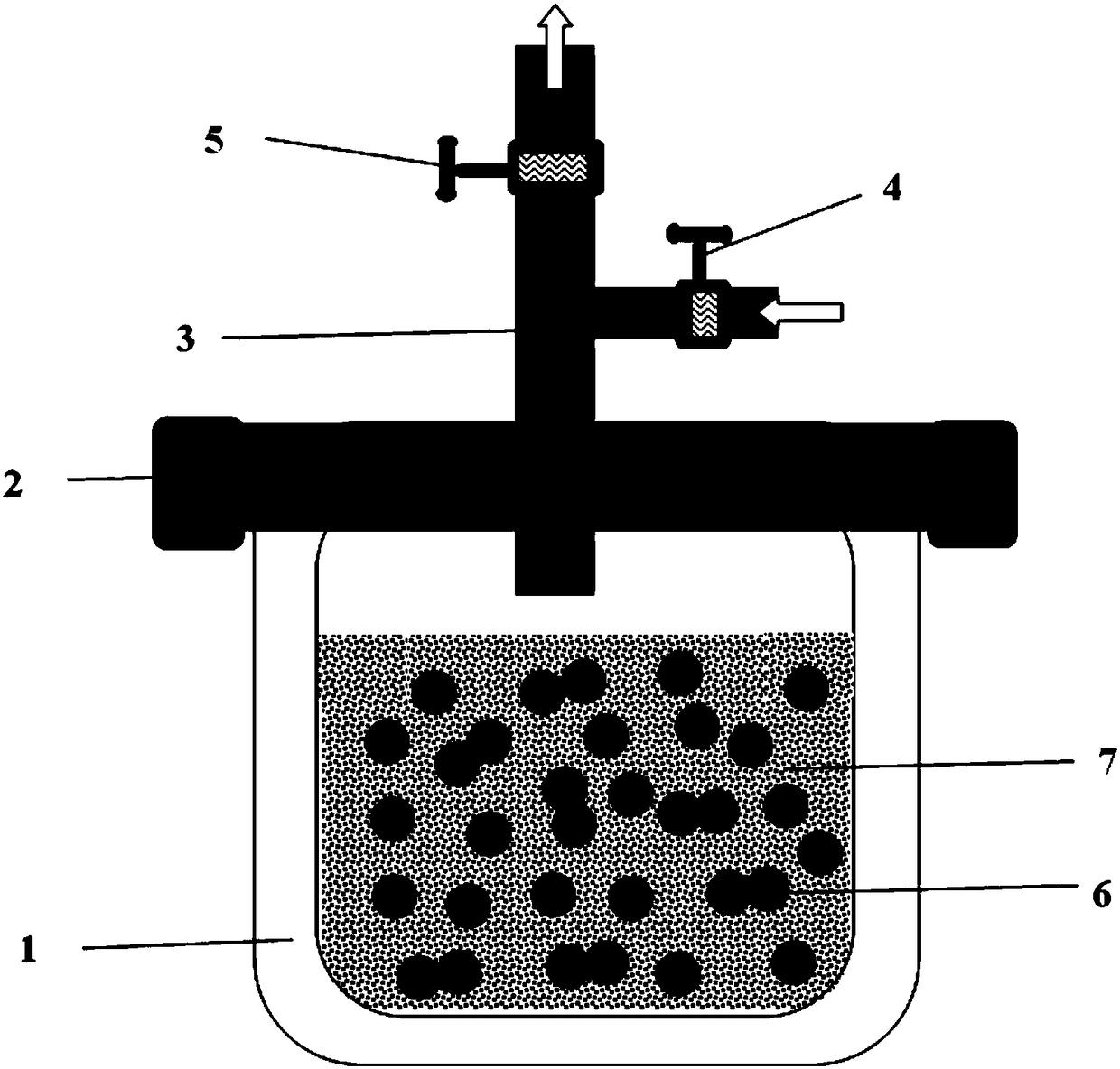

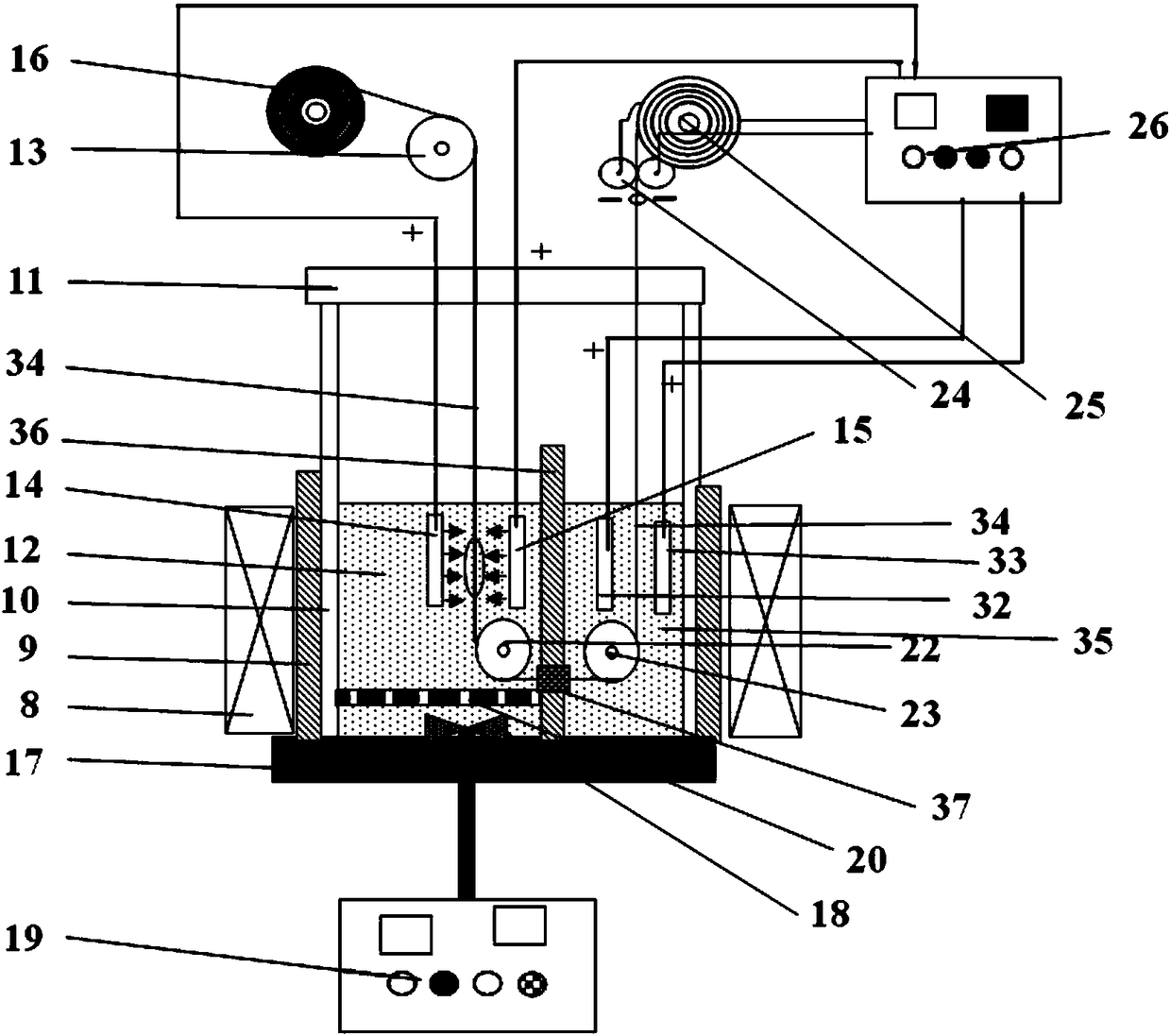

[0032] see figure 1 , figure 2 and image 3 , This embodiment provides a device for continuously preparing high-silicon silicon steel strips under a low-intensity magnetic field, including a device for preparing modified iron-silicon particles and an electroplating device for continuously preparing high-silicon silicon steel strips.

[0033] The device for preparing modified iron-silicon particles comprises a ball milling tank 1, a ball milling tank cover 2 is arranged on the ball milling tank 1, one end of the air guide pipe 3 is even inside the ball milling tank 1, and the other end passes through the ball milling tank cover 2 and even the inside of the ball milling tank 1. Externally, the other end of the air guide tube 3 is divided into two branches, and the first ball valve 4 and the second ball valve 5 are respectively arranged on the two branches in sequence.

[0034]The electroplating device for continuously preparing high-silicon silicon steel strips includes a mag...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com