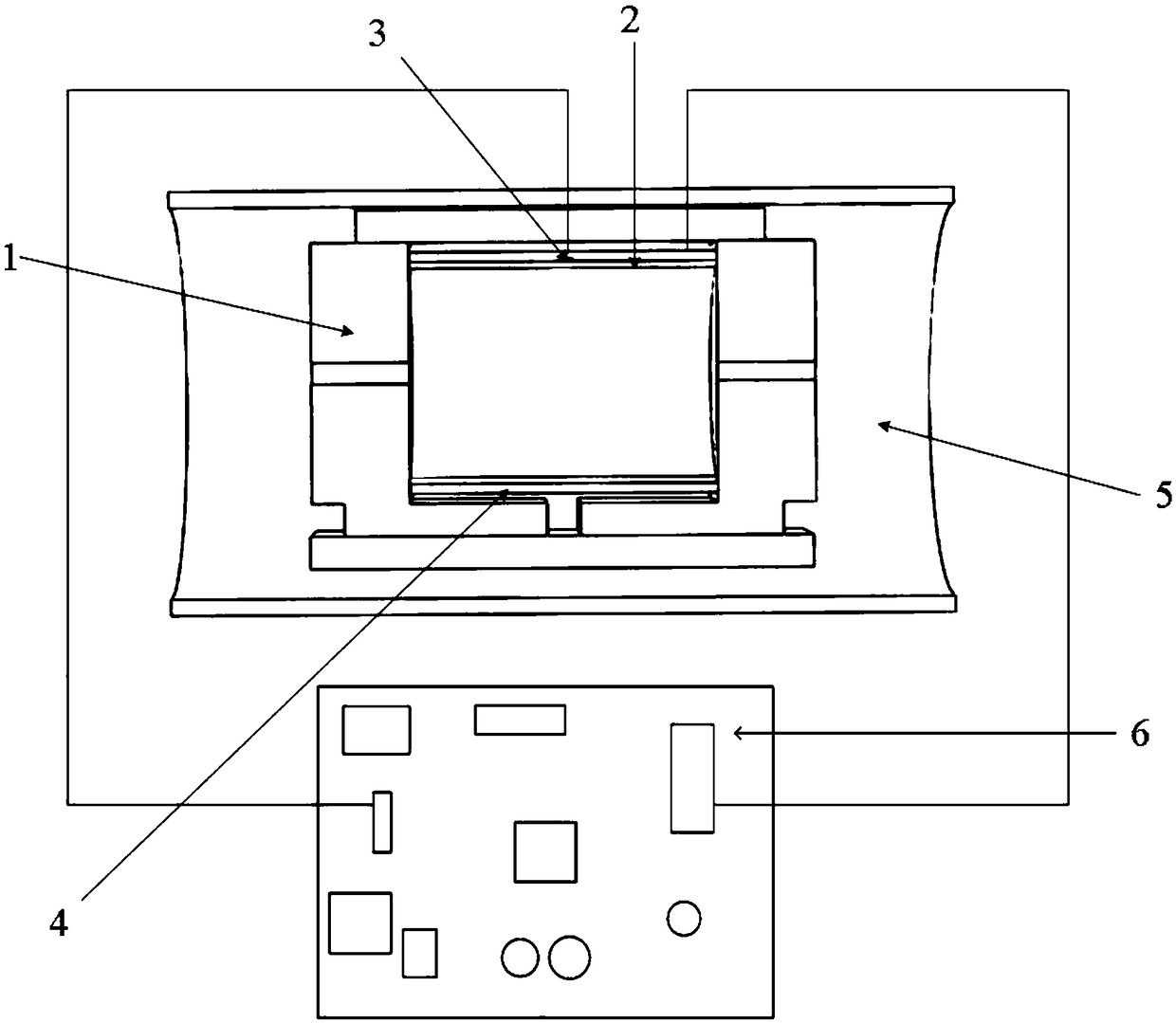

Gas multi-pass cell temperature control system and method based on self-adaptive interval PID control

A temperature control system and self-adaptive technology, which are applied to electric controllers, controllers with specific characteristics, and temperature control by electric means, can solve the problems of complex structure of gas multi-pass cells and large thermal response time constant, etc. Achieve no overshoot stabilization time, reduce heat exchange, and control precise effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

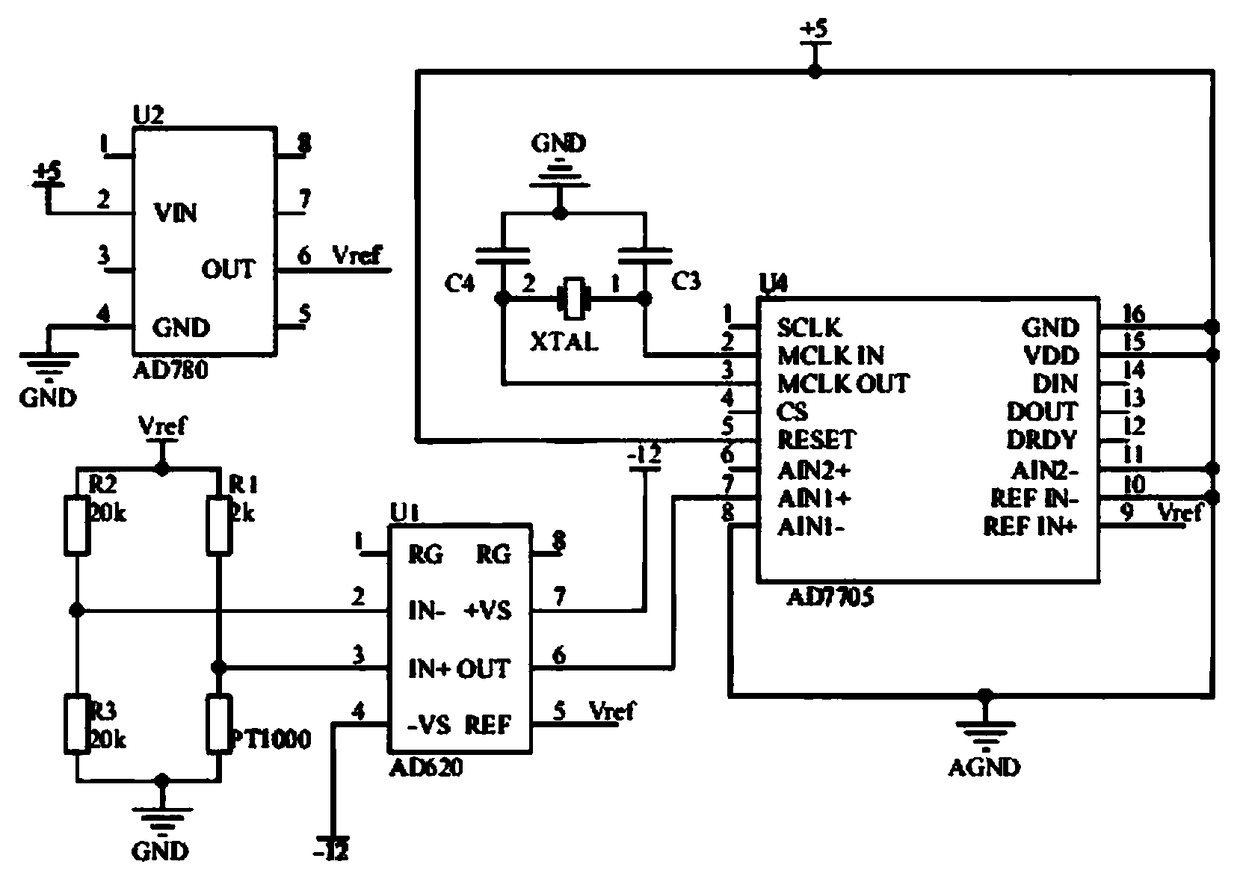

[0050] When the gas to be measured enters the gas multi-pass cell, the temperature of the gas multi-pass cell will change, and the resistance value of the platinum resistance PT1000 on the outer wall of the gas sample cell 2 will change, and the resistance value of the platinum resistance PT1000 will cause the Huygens bridge circuit to The output differential voltage signal changes, and the differential voltage signal is amplified by the instrument amplifier AD620, then sampled by the analog-to-digital converter AD7705, and the analog voltage signal is converted into a digital signal and input to the input terminal of the single-chip microcomputer STM32 for data processing.

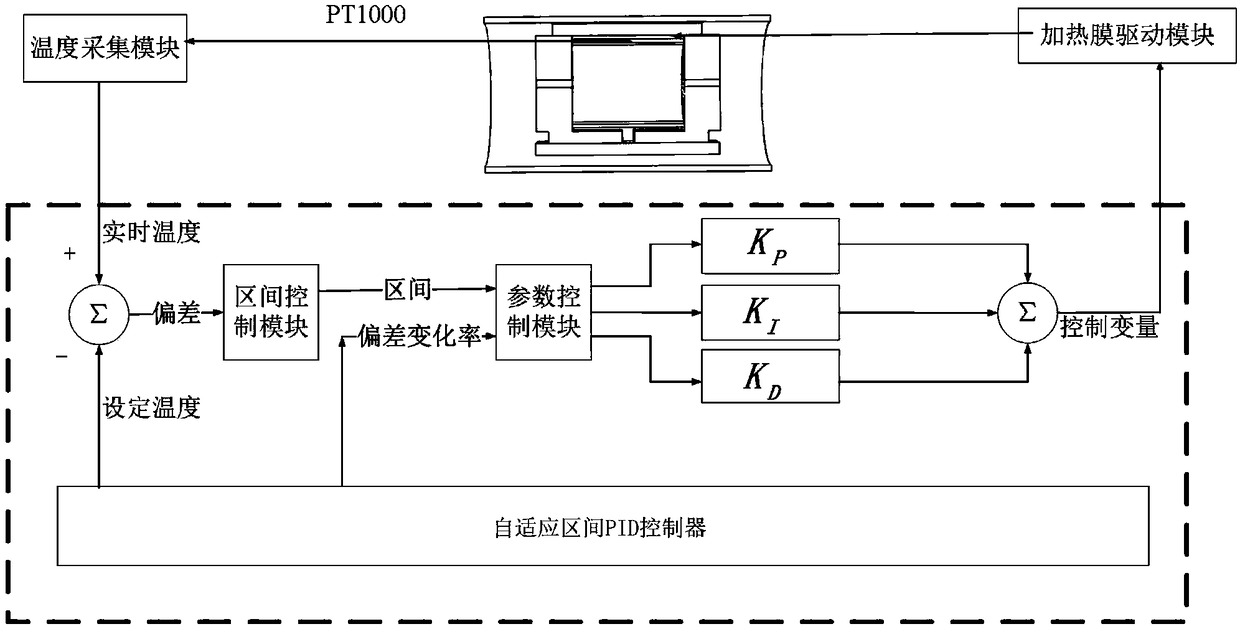

[0051] The control part uses an adaptive interval PID controller to collect the kth actual temperature value youk(k), and calculate the kth temperature deviation value e(k)=rin(k)-youk(k), where rin( k) represents the temperature set point. Input the obtained temperature deviation value e(k) as an input p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com