Functional cathode, qled and preparation method, light-emitting module and display device

A functionalized, cathode technology, applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve problems affecting the performance and stability of QLED devices, maintain interface stability and interface properties, prevent penetration, improve Effect of Electron Injection Efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

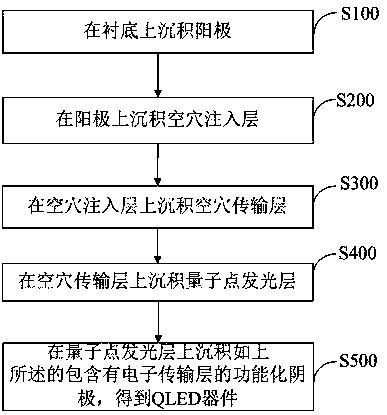

[0070] A quantum dot light-emitting diode containing a functional cathode, the preparation method is as follows:

[0071] Spin-coating a layer of PEDOT:PSS film on the ITO substrate as a hole injection layer;

[0072] Spin-coating a layer of PVK on the PEDOT:PSS hole injection layer as a hole transport layer;

[0073] Spin-coating a layer of CdSe / ZnS on the PVK hole transport layer as the quantum dot light-emitting layer;

[0074] Spin-coating a layer of ZnO on the CdSe / ZnS quantum dot light-emitting layer as an electron transport layer;

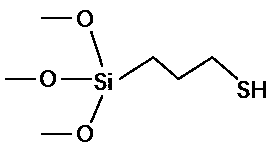

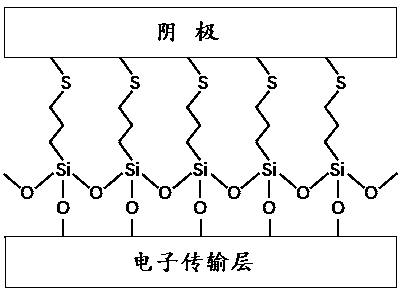

[0075] Then, take 200 uL of 50 mM mercaptopropyltrimethoxysilane ((CH 3 O) 3 SiC 3 H 6 SH) toluene solution was dropped on the above-mentioned ZnO electron transport layer, and a layer of mercaptopropyltrimethoxysilane was spin-coated at 5000 rpm and 30s spin-coating conditions;

[0076] Finally, a layer of Ag is vapor-deposited on the above-mentioned mercaptopropyltrimethoxysilane layer as a cathode to obtain a quantum dot light-emitting diode.

[0077...

Embodiment 2

[0079] A quantum dot light-emitting diode containing a functional cathode, the preparation method is as follows:

[0080] Spin-coating a layer of PEDOT:PSS film on the ITO substrate as a hole injection layer;

[0081] Spin-coating a layer of PVK on the PEDOT:PSS hole injection layer as a hole transport layer;

[0082] Spin-coating a layer of CdSe / ZnS on the PVK hole transport layer as the quantum dot light-emitting layer;

[0083] Spin-coating a layer of ZnO on the CdSe / ZnS quantum dot light-emitting layer as an electron transport layer;

[0084] Then, take 200 uL of 50 mM mercaptopropyltrimethoxysilane ((CH 3 O) 3 SiC 3 H 6 SH) toluene solution was dropped on the above-mentioned ZnO electron transport layer, and a layer of mercaptopropyltrimethoxysilane was spin-coated at 5000 rpm and 30s spin-coating conditions;

[0085] Next, a layer of Ag is evaporated on the above-mentioned mercaptopropyltrimethoxysilane layer as a cathode;

[0086] Finally, 100 uL of (11-mercaptoundecyl)trimethylamm...

Embodiment 3

[0089] A quantum dot light-emitting diode containing a functional cathode, the preparation method is as follows:

[0090] Spin-coating a layer of PEDOT:PSS film on the ITO substrate as a hole injection layer;

[0091] Spin-coating a layer of TFB on the PEDOT:PSS hole injection layer as a hole transport layer;

[0092] Spin-coating a layer of CdSe / ZnS on the TFB hole transport layer as the quantum dot light-emitting layer;

[0093] Spin-coating a layer of ZnO on the CdSe / ZnS quantum dot light-emitting layer as an electron transport layer;

[0094] Then, take 200 uL of 60 mM mercaptopropyltriethoxysilane ((C 2 H 5 O) 3 SiC 3 H 6 SH) toluene solution was dropped on the above ZnO electron transport layer, and a layer of mercaptopropyltriethoxysilane was spin-coated at 5000 rpm, 30s spin coating conditions;

[0095] Next, a layer of Ag is vapor-deposited as a cathode on the mercaptopropyltriethoxysilane layer;

[0096] Finally, take 100 uL of (11-mercaptoundecyl)trimethylammonium bromide dimet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com