LASO-coated octahedral structural lithium nickel manganate composite material and preparation method thereof

A technology of lithium nickel manganese oxide and composite materials, which is applied in the field of new energy materials, can solve the problems of battery cycle performance degradation, side reactions, etc., and achieve the effects of reducing oxidation and decomposition reactions, good effect, and easy preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

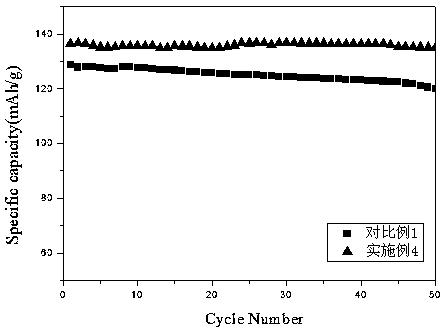

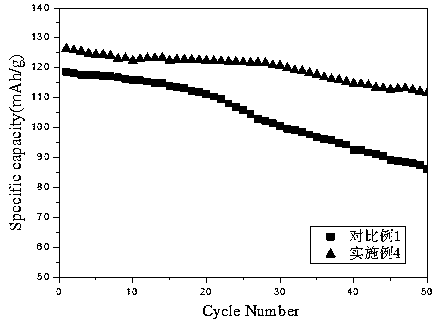

[0025] Preparation of 0.2% LASO-coated lithium nickel manganese oxide cathode material

[0026] Accurately weigh aluminum nitrate nonahydrate and citric acid monohydrate in ethanol-water solution according to coating amount and stoichiometric ratio, and magnetically stir until dissolved, wherein the volume ratio of ethanol to water in ethanol-water solution is 1:1, Al 3+ : The ratio (molar ratio) of citric acid to 1:1; Weigh 5g of lithium nickel manganese oxide positive electrode material in Comparative Example 1 in the above solution, stir for 4h to disperse; disperse ethyl silicate at a volume ratio of 1:10 In ethanol, slowly add dropwise to the above solution according to the coating amount and stoichiometric ratio, and continue to stir; disperse ethyl silicate in ethanol according to the coating amount stoichiometric ratio, slowly add dropwise to the above solution, continue Stir for 2 hours; use 1mol / L LiOH solution to adjust the pH of the solution to about 11, and contin...

Embodiment 2

[0028] Preparation of 0.4%LASO-coated lithium nickel manganese oxide cathode material

[0029] Accurately weigh aluminum nitrate nonahydrate and citric acid monohydrate in ethanol-water solution according to coating amount and stoichiometric ratio, and magnetically stir until dissolved, wherein the volume ratio of ethanol to water in ethanol-water solution is 1:1, Al 3+ : citric acid is the ratio (molar ratio) of 1:1; Take by weighing 5g lithium nickel manganese oxide cathode material in the above-mentioned solution in comparative example 1, stir 4h to make it disperse; Ethyl silicate is dispersed in ethanol, according to package The coating amount and stoichiometric ratio were slowly added to the above solution drop by drop, and continued to stir for 2 hours; adjusted the pH of the solution to about 11 with 1mol / L LiOH solution, and continued to stir for 1 hour; Covering amount and stoichiometric ratio Lithium excess 5% is mixed with lithium carbonate and poured into a ball mil...

Embodiment 3

[0031] Preparation of 0.6%LASO-coated lithium nickel manganese oxide cathode material

[0032] Accurately weigh aluminum nitrate nonahydrate and citric acid monohydrate in ethanol-water solution according to coating amount and stoichiometric ratio, and magnetically stir until dissolved, wherein the volume ratio of ethanol to water in ethanol-water solution is 1:1, Al 3+ : citric acid is the ratio (molar ratio) of 1:1; Take by weighing 5g lithium nickel manganese oxide cathode material in the above-mentioned solution in comparative example 1, stir 4h to make it disperse; Ethyl silicate is dispersed in ethanol, according to package The coating amount and stoichiometric ratio were slowly added to the above solution drop by drop, and continued to stir for 2 hours; adjusted the pH of the solution to about 11 with 1mol / L LiOH solution, and continued to stir for 1 hour; Covering amount and stoichiometric ratio Lithium excess 5% is mixed with lithium carbonate and poured into a ball m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com