Zinc-based battery anode material and preparation method thereof

A negative electrode material, technology of zinc-based battery, applied in battery electrodes, circuits, electrical components, etc., to achieve the effect of simple preparation method and inhibiting the phenomenon of dendrite growth piercing through the diaphragm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

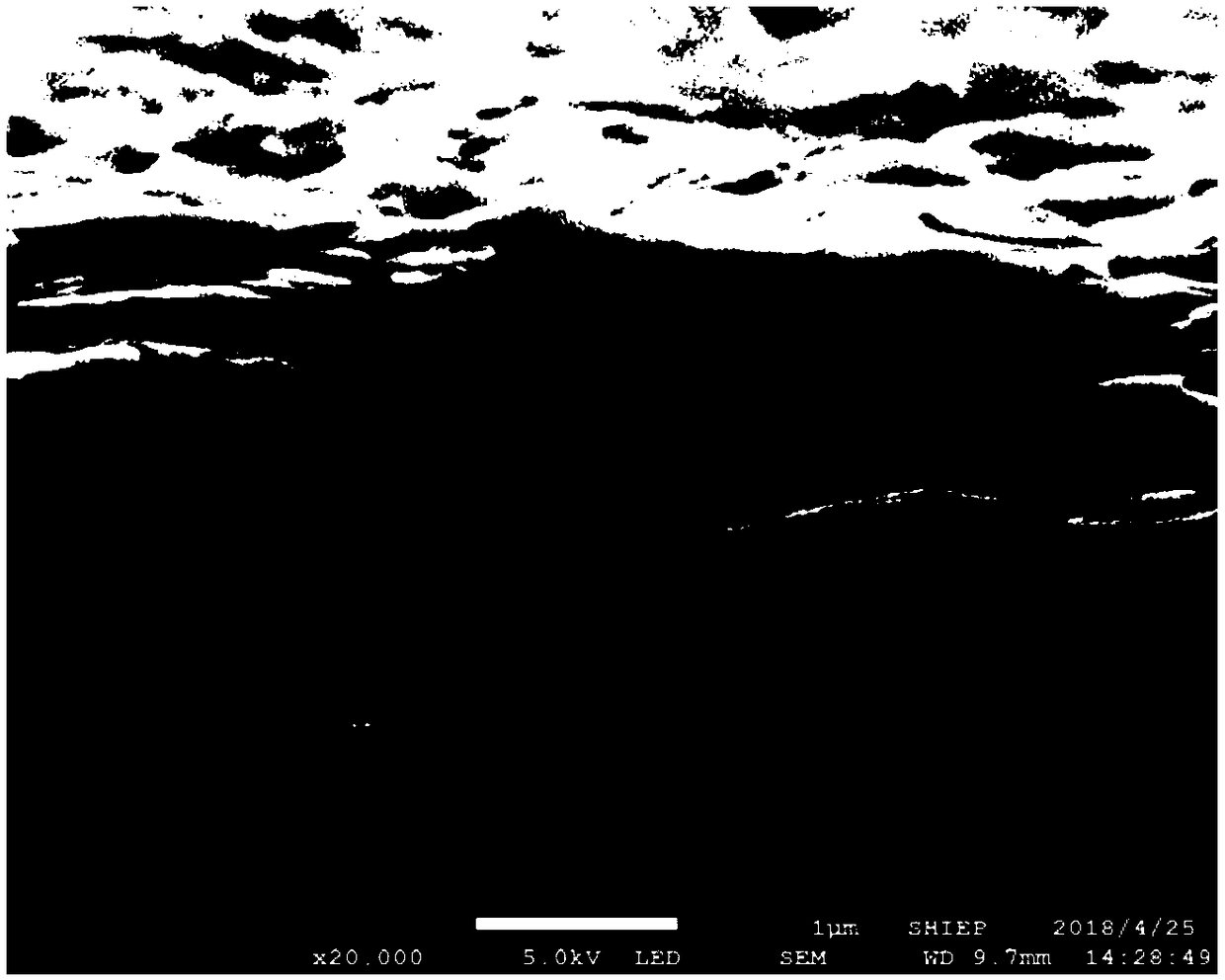

[0030] A preparation method for a zinc ion secondary battery negative electrode material, comprising the steps of:

[0031] (1) Pretreatment of metal zinc: Cut a zinc sheet with a thickness of 0.3 mm into a disc with a diameter of 16 mm, place it in acetone, ultrasonically clean it for 30 minutes, and then wash it with absolute ethanol and deionized water in order to remove zinc Oil stains on the surface of the zinc sheet, then soaked in 1% hydrochloric acid for 10 seconds to remove the oxide layer on the surface of the zinc sheet, then rinsed with deionized water, and dried for later use;

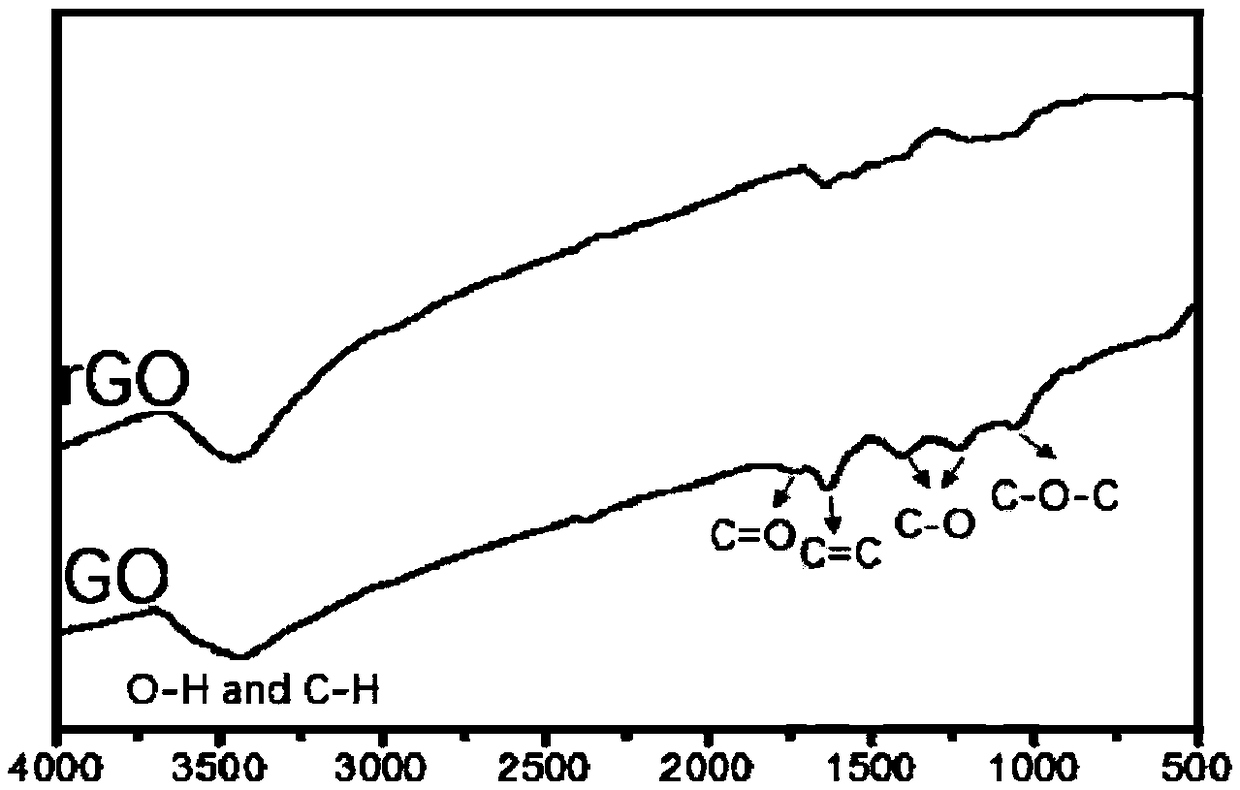

[0032] (2) Preparation of graphene oxide solution: use 32-mesh flake graphite as raw material, use hummers to prepare graphite oxide, after centrifugal cleaning, collect graphite oxide in the centrifuge tube and freeze-dry, weigh 0.1g of graphite oxide after drying and add 1L to remove Ionized water, after stirring and ultrasonic stripping, a graphene oxide aqueous solution with uniform co...

Embodiment 3

[0046] (1) Pretreatment of metal zinc: Cut a zinc sheet with a thickness of 0.1 mm into a disc with a diameter of 15 mm, place it in acetone, ultrasonically clean it for 50 minutes, and then wash it with absolute ethanol and deionized water in order to remove zinc Oil stains on the surface of the zinc sheet, then soaked in 3% hydrochloric acid for 5 seconds to remove the oxide layer on the surface of the zinc sheet, then rinsed with deionized water, and dried for later use

[0047] (2) Preparation of graphene oxide solution: use 128-mesh flake graphite as raw material, use hummers to prepare graphite oxide, after centrifugal cleaning, collect graphite oxide in the centrifuge tube and freeze-dry, weigh 2 g of dried graphite oxide and add 1 L of deionized water, a graphene oxide aqueous solution with uniform color was obtained after stirring and ultrasonic stripping.

[0048] (3) Graphene oxide is reduced and adsorbed on the surface of the zinc sheet: put the pretreated zinc she...

Embodiment 4

[0052] (1) Pretreatment of metal zinc: Cut a zinc sheet with a thickness of 0.1 mm into a disc with a diameter of 15 mm, place it in acetone, clean it ultrasonically for 30 minutes, and then wash it with absolute ethanol and deionized water in order to remove zinc Oil stains on the surface of the zinc sheet, then soaked in 2% hydrochloric acid for 5 seconds to remove the oxide layer on the surface of the zinc sheet, then rinsed with deionized water, and dried for use

[0053] (2) Preparation of graphene oxide solution: use 128-mesh flake graphite as raw material, use hummers to prepare graphite oxide, after centrifugal cleaning, collect graphite oxide in the centrifuge tube and freeze-dry, weigh 3g of dried graphite oxide and add 1L deionized water, a graphene oxide aqueous solution with uniform color was obtained after stirring and ultrasonic stripping.

[0054] (3) Graphene oxide is reduced and adsorbed on the surface of the zinc sheet: put the pretreated zinc sheet into the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap