A heteroatom-doped carbon microsphere-supported oxygen reduction catalyst of iron phosphide nanoparticles and its preparation method

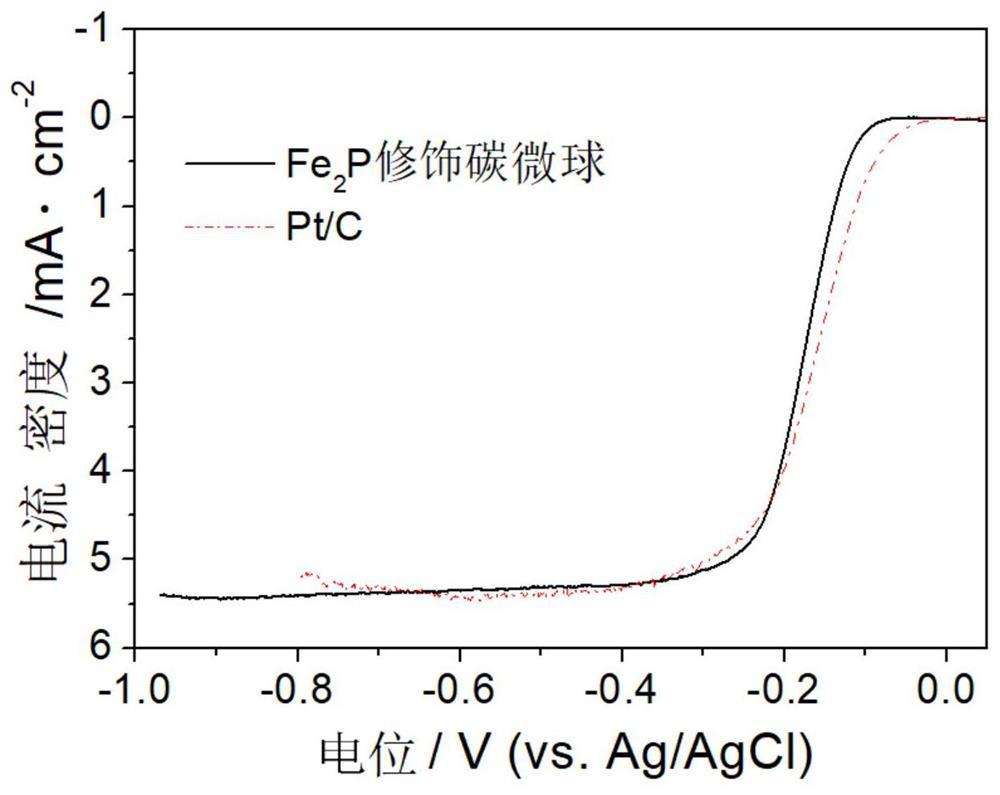

A nanoparticle, iron phosphide technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of poor controllability, poor uniformity of micro-nano structure, affecting material properties, etc. Uniform size, uniform micro-nano structure, simple and efficient process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

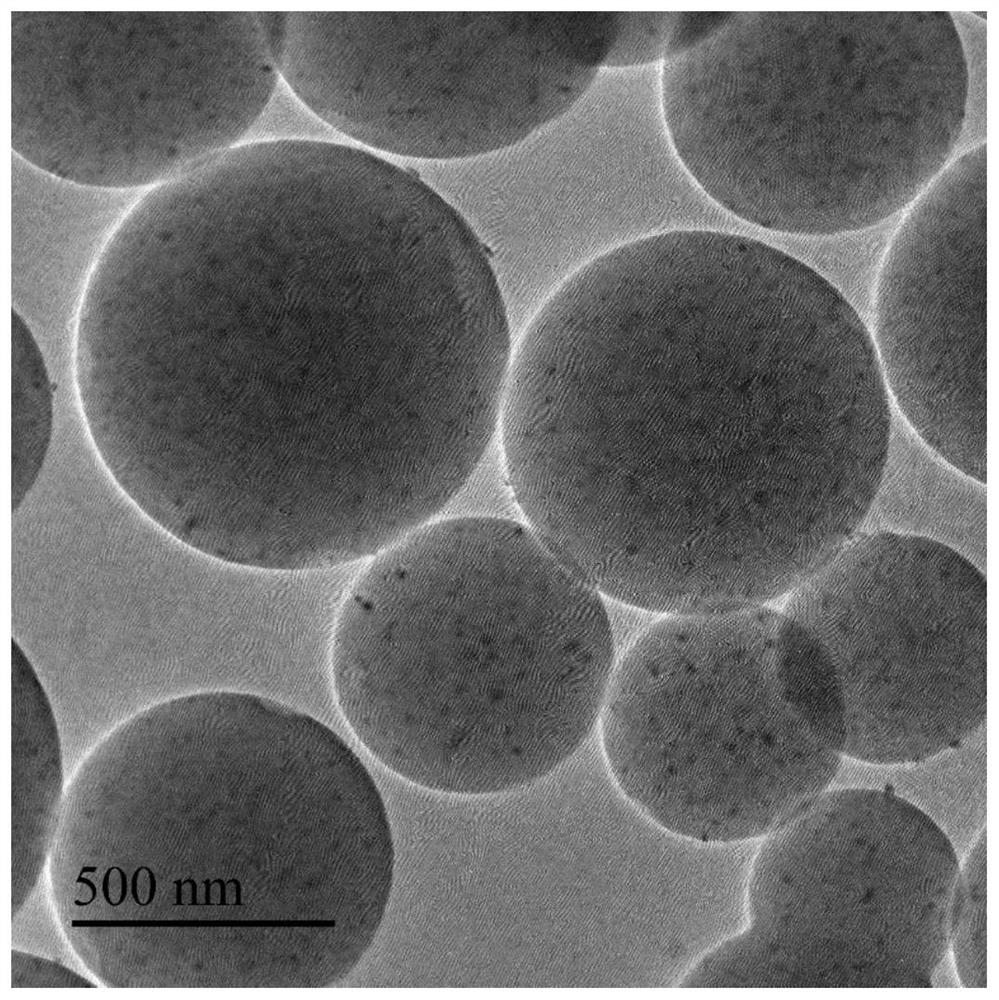

[0028] In this example, the preparation of the heteroatom-doped carbon microsphere-supported iron phosphide nanoparticle catalyst is realized through the following steps:

[0029] Step 1, weigh 0.5g of hexachlorocyclotriphosphazene and 1.1g of 4,4'-dihydroxydiphenyl sulfone into a single-necked flask containing 100mL of acetone, and make hexachlorocyclotriphosphazene Dissolve with 4,4'-dihydroxydiphenyl sulfone; add 2mL triethylamine to the solution, keep the reaction temperature at 40°C, and react for 8 hours to obtain a milky white dispersion; after the reaction, centrifuge, wash with water, and dry to obtain a white Polyphosphazene microspheres;

[0030] Step 2, weigh 0.2 g of ferrous sulfate and dissolve it in 1 mL of water. After fully dissolving, add the solution to 50 mL of the aqueous dispersion of polyphosphazene microspheres with a concentration of 10 mg / mL; stir for 12 hours to make the polyphosphazene microspheres fully Adsorb ferrous sulfate; after the reaction, ...

Embodiment 2

[0033] In this example, the preparation of the heteroatom-doped carbon microsphere-supported iron phosphide nanoparticle catalyst is realized through the following steps:

[0034] Step 1, weigh 0.5g of hexachlorocyclotriphosphazene and 0.5g of p-phenylenediamine and dissolve in 60mL of acetone, measure 2mL of triethylamine and add it to the above solution, after fully dissolving, transfer the solution to 100mL polytetrafluoroethylene In a vinyl fluoride-lined digestion tank, react at 150°C for 3 hours; after the reaction, centrifuge, wash with ethanol, and dry to obtain light yellow polyphosphazene microspheres;

[0035] Step 2, weigh 0.1 g of ferrous chloride tetrahydrate and dissolve it in 1 mL of water. After fully dissolving, add the solution to 50 mL of the aqueous dispersion of polyphosphazene microspheres with a concentration of 10 mg / mL; stir for 12 hours to make the polyphosphazene The microspheres fully adsorb ferrous chloride tetrahydrate; after the reaction, centri...

Embodiment 3

[0038] In this example, the preparation of the heteroatom-doped carbon microsphere-supported iron phosphide nanoparticle catalyst is realized through the following steps:

[0039] Step 1, weigh 0.5g of hexachlorocyclotriphosphazene and 0.5g of p-phenylenediamine and dissolve in 60mL of acetone, measure 2mL of triethylamine and add it to the above solution, after fully dissolving, transfer the solution to 100mL polytetrafluoroethylene In a vinyl fluoride-lined digestion tank, react at 150°C for 3 hours; after the reaction, centrifuge, wash with ethanol, and dry to obtain light yellow polyphosphazene microspheres;

[0040]Step 2, take 0.1 g of iron acetate and dissolve it in 1 mL of ethanol, and after fully dissolving, add the solution to 50 mL of the ethanol dispersion of polyphosphazene microspheres with a concentration of 10 mg / mL; stir for 6 hours to make the polyphosphazene microspheres Fully adsorb iron acetate; after the reaction, centrifuge, wash, and dry to obtain polyp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com