Repairing method of W target material

A repair method and target material technology, which is applied in metal material coating process, ion implantation plating, coating, etc., can solve the problems that affect the performance of W target material, the service life of products, the inability to repair and reuse, and the low reuse rate. , to achieve consistent three-point bending performance, performance improvement, and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

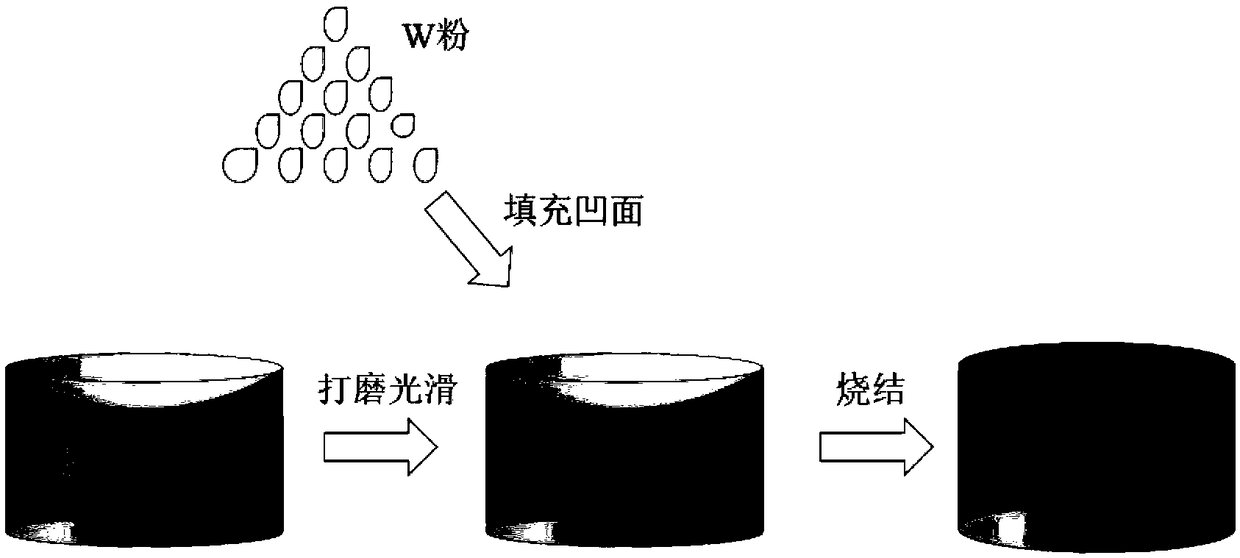

[0029] In this embodiment, the W target cylindrical ingot of Φ30mm×30mm is repaired, and the specific steps are as follows:

[0030] Step 1. Select a lathe worker to clean the surface of the W target to be repaired to remove impurities and oxide layers, polish it with 1500-grit sandpaper, and then use the Archimedes drainage method to calculate the amount of time to fill the surface of the W target to be repaired. The volume of W powder required for the uneven defect area;

[0031] Weigh the corresponding volume of W powder for subsequent use;

[0032] Step 2. Put the cleaned W target into the graphite mold, then add W powder, and make the W powder on the surface of the W target to be repaired; use a manual hydraulic press to install the graphite mold with the W target and W powder Carry out preloading, the pressure is ~10MPa;

[0033] Step 3. Wrap the graphite mold with ~5mm thick carbon felt at the same height as the graphite mold after pre-pressing, and then place it in t...

Embodiment 2

[0040] In this embodiment, the W target cylindrical ingot of Φ30mm×30mm is repaired, and the specific steps are as follows:

[0041] Step 1. Select a lathe worker to clean the surface of the W target to be repaired to remove impurities and oxide layers, polish it with 1500-grit sandpaper, and then use the Archimedes drainage method to calculate the amount of time to fill the surface of the W target to be repaired. The volume of W powder required for the uneven defect area;

[0042] Weigh the corresponding volume of W powder for subsequent use;

[0043] Step 2. Put the cleaned W target into the graphite mold, then add W powder, and make the W powder on the surface of the W target to be repaired; use a manual hydraulic press to install the graphite mold with the W target and W powder Carry out preloading, the pressure is ~10MPa;

[0044] Step 3. Wrap the graphite mold with ~5mm thick carbon felt at the same height as the graphite mold after pre-pressing, and then place it in t...

Embodiment 3

[0051] In this embodiment, the W target cylindrical ingot of Φ30mm×30mm is repaired, and the specific steps are as follows:

[0052] Step 1. Select a lathe worker to clean the surface of the W target to be repaired to remove impurities and oxide layers, polish it with 1500-grit sandpaper, and then use the Archimedes drainage method to calculate the amount of time to fill the surface of the W target to be repaired. The volume of W powder required for the uneven defect area;

[0053] Weigh the corresponding volume of W powder for subsequent use;

[0054]Step 2. Put the cleaned W target into the graphite mold, then add W powder, and make the W powder on the surface of the W target to be repaired; use a manual hydraulic press to install the graphite mold with the W target and W powder Carry out preloading, the pressure is ~10MPa;

[0055] Step 3. Wrap the graphite mold with ~5mm thick carbon felt at the same height as the graphite mold after pre-pressing, and then place it in th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| aspect ratio | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com