Preparation method of a one-pass foaming two-pass frosted surface glove

A matte surface and glove technology, used in household components, household appliances, other household appliances, etc., can solve the problems of insufficient grip, low friction, rigidity, etc., to achieve good protection, improve friction, and good grip. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A kind of preparation method of the acrylonitrile-butadiene glove that one time foaming fully dips twice frosted surface, concrete steps are as follows:

[0037] (1) Raw materials: pre-vulcanized carboxylated nitrile latex, thickener, potassium ricinoleate, Glauber's salt, KOH, sodium dodecylbenzenesulfonate, etc.;

[0038] (2) Glue adjustment:

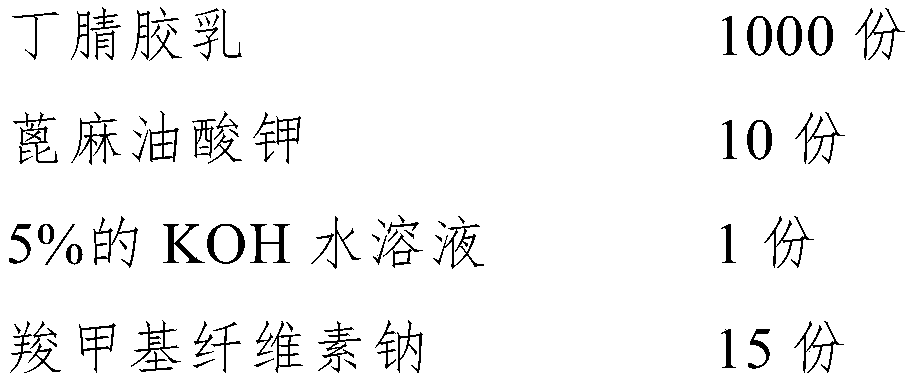

[0039] For the first impregnating glue, the mass ratio of the glue is as follows, so that the foaming ratio can reach 1.5 times,

[0040]

[0041] The second dipping glue, the quality ratio of the glue material is as follows

[0042]

[0043] (3) Preheating: put the glove embryo on the hand mold, and preheat the hand mold, soak the coagulant (methanol: calcium nitrate by mass ratio is 100:2), after 30 seconds of uniform solution, the glove embryo is fully immersed for the first time Dipping glue, then dipping in the second coagulant (water: calcium chloride is 100:15 by mass ratio), after 5 minutes of uniform solution, ...

Embodiment 2

[0049] A kind of preparation of the nitrile gloves of once foaming and semi-immersing twice frosted surface, concrete steps are as follows:

[0050] (1) Raw materials: pre-vulcanized carboxylated nitrile latex, thickener, potassium oleate, sodium chloride, KOH, polyoxyethylene alkyl ether, etc.;

[0051] (2) Glue adjustment:

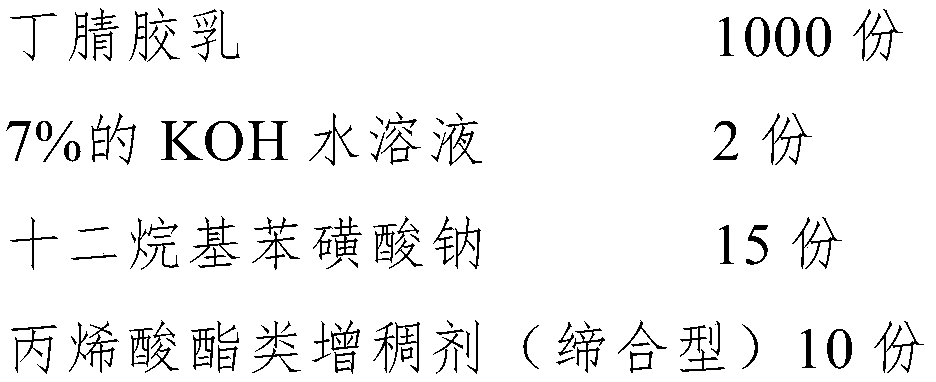

[0052] For the first impregnating glue, the mass ratio of the glue is as follows, so that the foaming ratio can reach 1.1 times,

[0053]

[0054] The second dipping glue, the quality ratio of the glue material is as follows

[0055]

[0056]

[0057] (3) Preheating: put the glove embryo on the hand mold, preheat the hand mold, soak the coagulant (ethanol: calcium nitrate in a mass ratio of 100:3), and soak the palm of the glove embryo after 30 seconds. , the back of the hand is dipped in half of the first dipping glue, and then soaked in the second coagulant (ethanol: calcium chloride is 100:18 by mass ratio), and after 4 minutes of uniform s...

Embodiment 3

[0063] A kind of latex glove preparation that foams once and fully soaks frosted surface twice, concrete steps are as follows:

[0064] (1) Material preparation: pre-vulcanized natural rubber latex, thickener, detergent, Glauber's salt, KOH, sodium dodecylbenzenesulfonate, etc.;

[0065] (2) Glue adjustment:

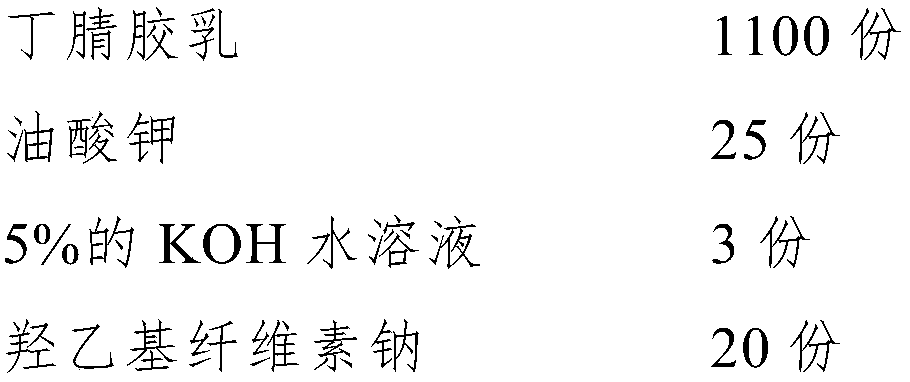

[0066] The first impregnation glue, its glue material is prepared according to the following mass parts, so that the foaming multiple can reach 1.4 times,

[0067]

[0068] The second impregnating glue, the quality ratio of the glue is as follows

[0069]

[0070] (3) Preheating: put the glove embryo on the hand mold, and preheat the hand mold, soak the first coagulant (methanol: calcium nitrate by mass ratio is 100:3), after 30 seconds, the glove embryo is fully immersed The first dipping glue, and then dipping the second coagulant (methanol: calcium chloride is 100:5 by mass ratio), and after 5 minutes of uniform solution, the glove palm is soaked in the second...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com