Method for modifying graphene based on carbene and preparation method of graphene-doped anticorrosion coating

A graphene and modification technology, applied in the field of materials, can solve problems such as affecting the special properties of the graphene surface, and achieve the effect of increasing the variety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

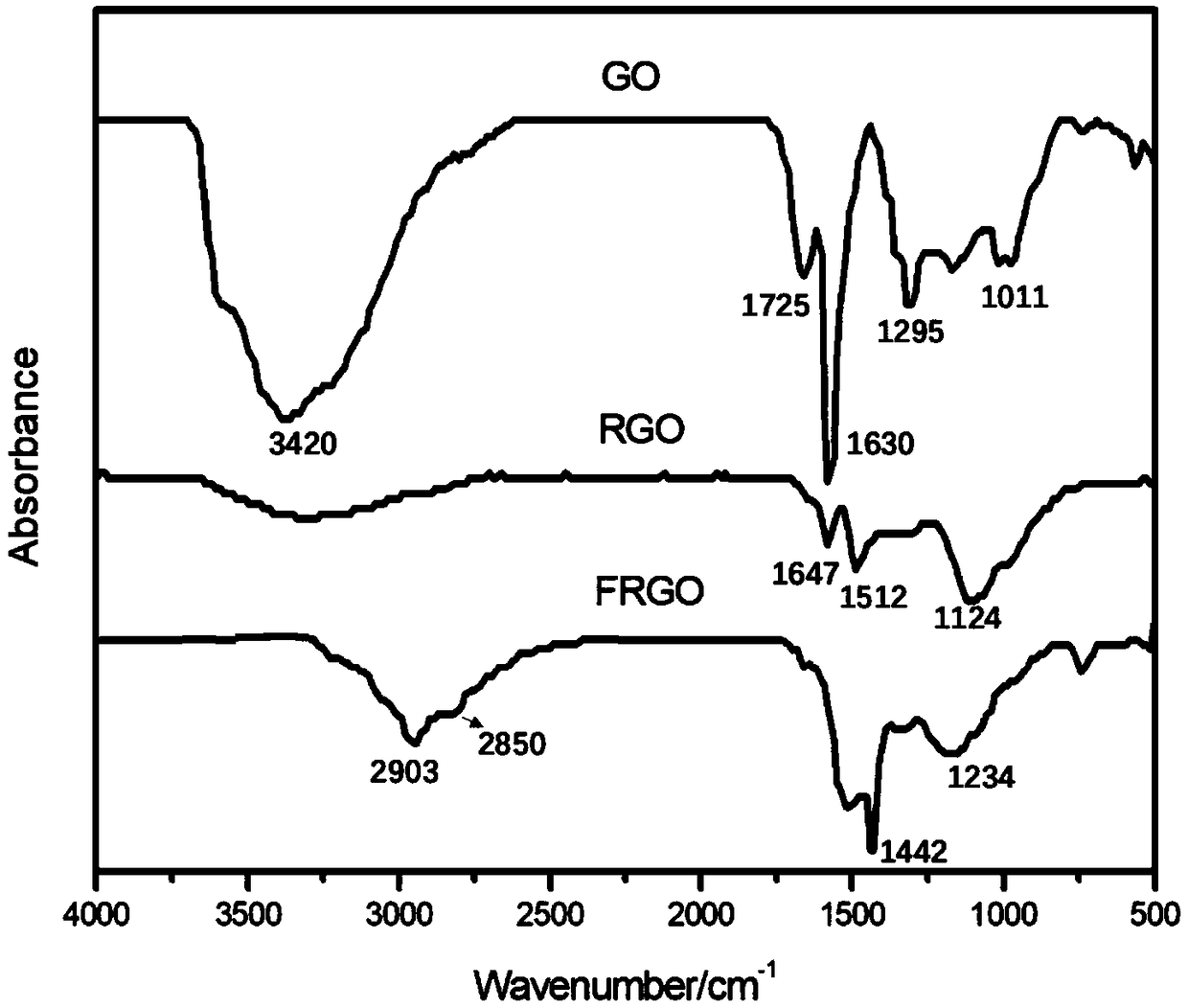

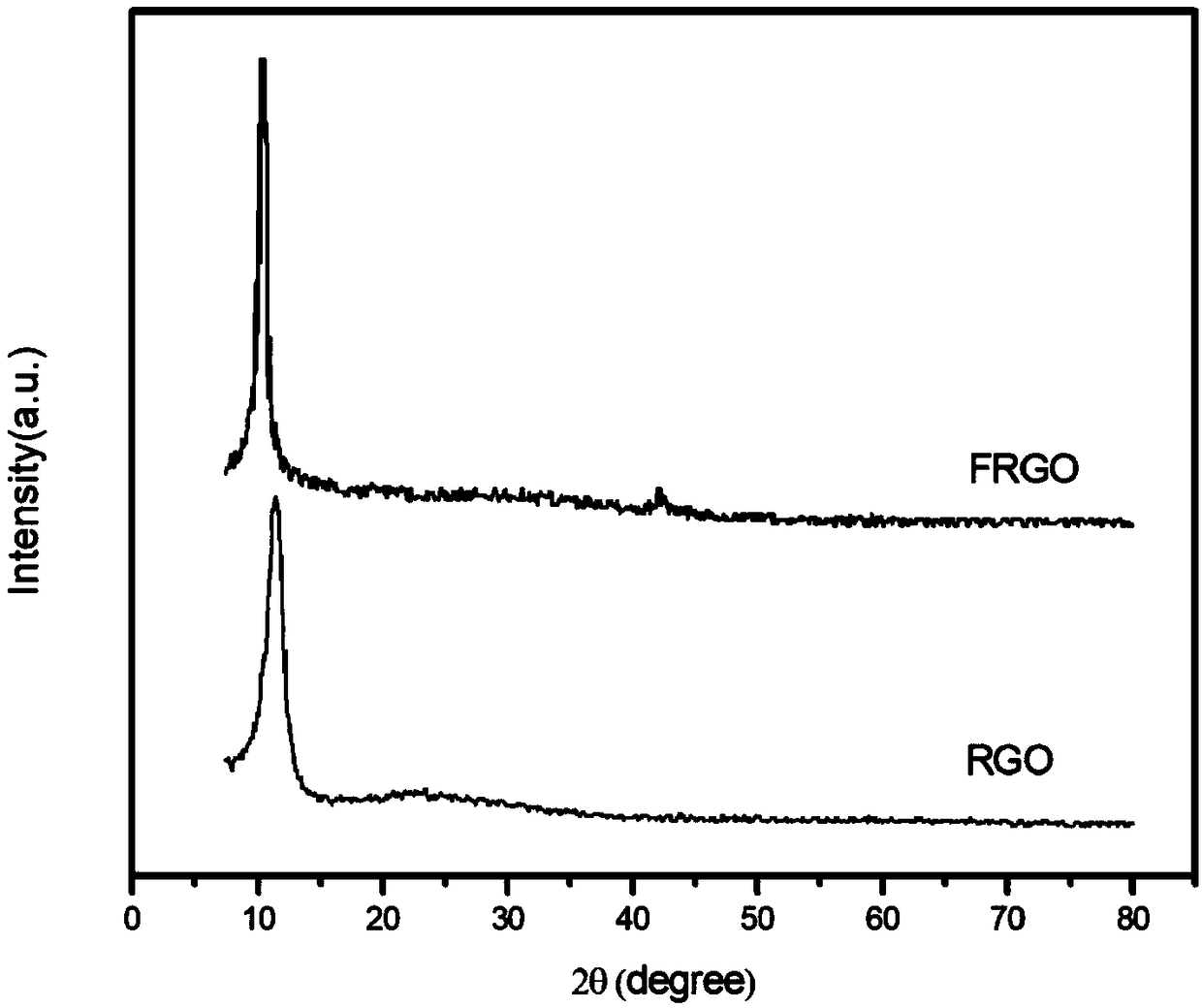

[0063] The method of carbene covalent modification of graphene:

[0064] The above-obtained diaziridine compound was added to dichlorotoluene for 30min in the dark for reaction, stirred for 15min, until uniformly mixed, wherein, in the mixed solution, the concentration of the diaziridine compound was 1mmol / L~100mmol / L. Then, 100 mg of graphene was added to the dichlorotoluene solution of the diaziridine intermediate, and reacted for 1 h in an ultraviolet photoreactor, wherein the wavelength of the light in the ultraviolet photoreactor was 280-190 nm; The oil bath was heated to 80 ℃, and the temperature was maintained, and stirred for 24 hours; finally, vacuum filtration was used, and deionized water and ethanol were used to wash three times respectively, and the filter cake obtained by suction filtration was vacuum-dried at room temperature for 24 hours, and ground to obtain modified graphene .

[0065] Wherein, the influence of the dosage ratio of graphene and diaziridine co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com