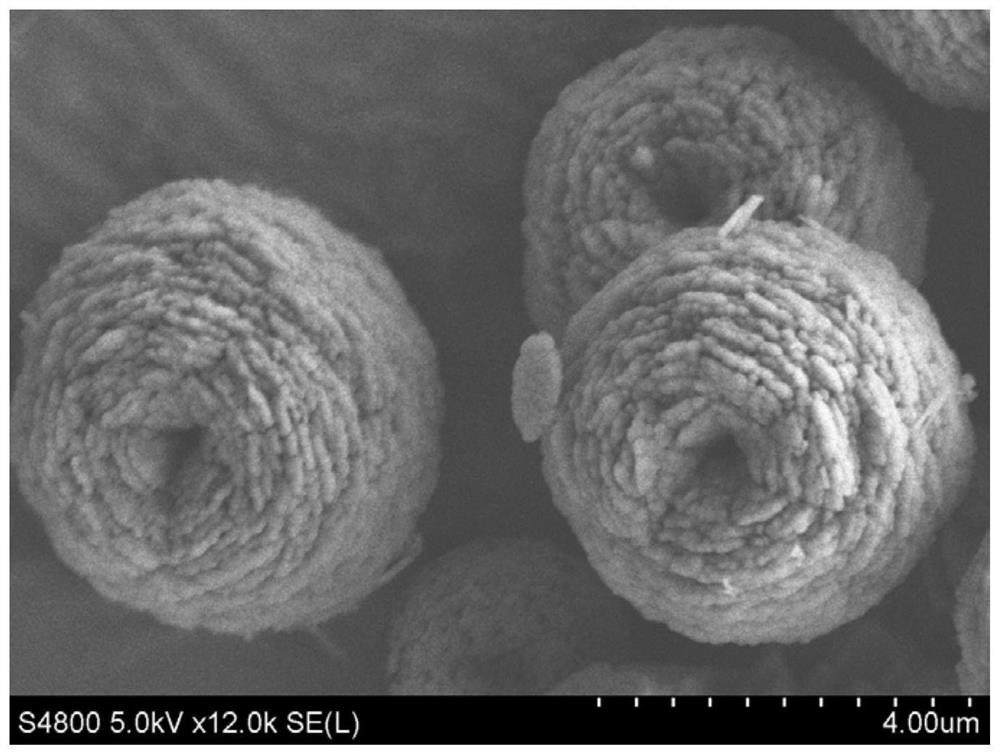

A kind of preparation method of layered structure microsphere precipitated calcium carbonate

A technology for precipitating calcium carbonate and layered structure, applied in the direction of calcium carbonate/strontium/barium, chemical instruments and methods, calcium/strontium/barium compounds, etc. and other problems, to achieve good economic and social benefits, simple and feasible process, and good application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

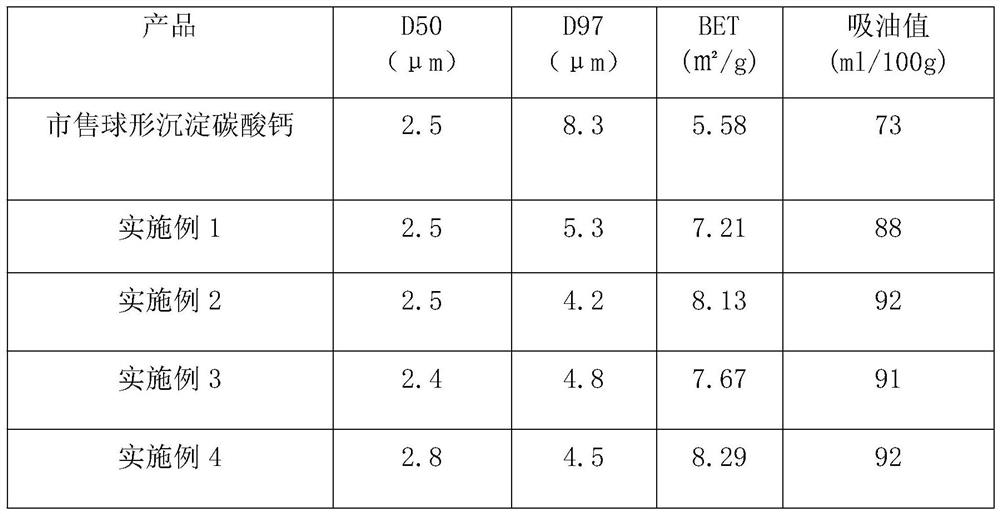

Embodiment 1

[0032] A preparation method for layered structure microsphere precipitated calcium carbonate, is characterized in that, comprises the steps:

[0033] (1) Limestone is calcined at 1150°C for 300 minutes to obtain quicklime, and the prepared quicklime and water are digested according to a mass ratio of 1:5 to obtain lime milk, which is passed through a 100-mesh sieve to remove slag and refine, adjust The lime milk concentration reaches 10g / L to obtain lime milk slurry;

[0034] (2) After heating the lime milk slurry to 40°C, pump it to the carbonization tower, and add 2% CaCl on a dry basis of calcium carbonate to the lime milk 2 , after stirring evenly, then pass into the mixed gas containing 33% carbon dioxide, do not stir during the reaction process, when the pH value of the slurry drops to 7.5, stop the reaction to obtain calcium carbonate slurry;

[0035] (3) After the calcium carbonate slurry is washed with absolute ethanol and suction-filtered, it is infrared-dried at 60...

Embodiment 2

[0037] A preparation method for layered structure microsphere precipitated calcium carbonate, is characterized in that, comprises the steps:

[0038] (1) Limestone is calcined at 1100°C for 400 minutes to obtain quicklime, and the prepared quicklime and water are digested according to a mass ratio of 1:8 to obtain lime milk, which is passed through a 100-mesh sieve to remove slag and refine, adjust The lime milk concentration reaches 50g / L to obtain lime milk slurry;

[0039](2) After heating the lime milk slurry to 60°C, pump it to the carbonization tower, and add 1% NaOH and 1% NaOH on a dry basis of calcium carbonate to the lime milk 2 CO 3 , after stirring evenly, then pass into the mixed gas that contains 45% carbon dioxide, the reaction process control stirring rate is 60r / min, when the slurry pH value drops to 7.5, stop reaction, obtain calcium carbonate slurry;

[0040] (3) After the calcium carbonate slurry is washed with absolute ethanol and suction-filtered, it is...

Embodiment 3

[0042] A preparation method for layered structure microsphere precipitated calcium carbonate, is characterized in that, comprises the steps:

[0043] (1) Limestone is calcined at 1250°C for 300 minutes to obtain quicklime, and the prepared quicklime and water are digested and reacted at a mass ratio of 1:10 to obtain lime milk, which is passed through a 100-mesh sieve to remove slag and refine, adjust The lime milk concentration reaches 100g / L to obtain lime milk slurry;

[0044] (2) After heating the lime milk slurry to 80°C, pump it to the carbonization tower, and add 1.5% Ca(NO3) on a dry basis of calcium carbonate to the lime milk 2 , after stirring evenly, then pass into the mixed gas that contains 15% carbon dioxide, the reaction process does not stir, and when the slurry pH value drops to 7.5, stop reaction, get calcium carbonate slurry; (3) calcium carbonate slurry is used without After washing with water and ethanol and suction filtration, infrared drying at 70°C, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com