Purification process for waste etching liquid from circuit boards

A technology for etching waste liquid and purification treatment, which is applied in filtration treatment, heating water/sewage treatment, degassed water/sewage treatment, etc. It can solve the problems of natural environmental hazards, damage to biological tissues, carcinogenicity, etc., and achieve broad market prospects , good economic and environmental benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

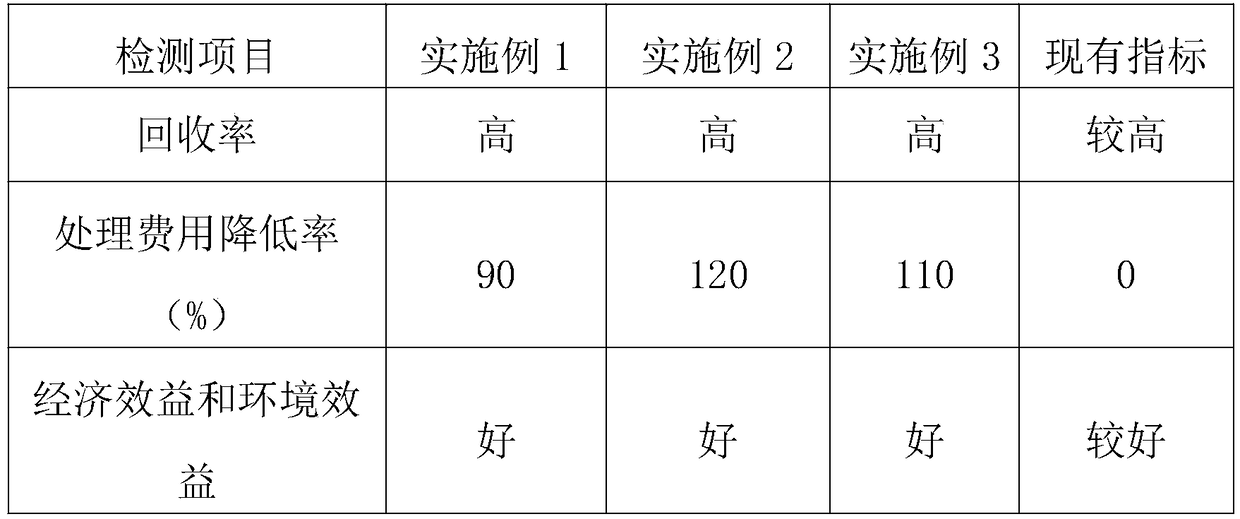

Examples

Embodiment 1

[0029] A purification treatment process for circuit board etching waste liquid, comprising the steps of:

[0030] (1) Neutralization reaction

[0031] First, the acidic etching waste liquid is added to the alkaline etching waste liquid, and the pH value of the mixed solution is adjusted, and a neutralization reaction occurs between the two to generate basic copper chloride precipitation, and the pH of the mixed solution is 5;

[0032] (2) Pressure filtration separation and pulping

[0033] The mixed liquid after the neutralization reaction is subjected to solid-liquid separation to obtain a liquid phase 1, and then adding water to the basic copper chloride obtained after the reaction to make a slurry to obtain a basic copper chloride slurry, and simultaneously adding water to quicklime to prepare a lime slurry, spare;

[0034] (3) Alkali conversion process

[0035] Then lime slurry is added in the basic copper chloride slurry, stirred to obtain the mixture, the time of the ...

Embodiment 2

[0047] A purification treatment process for circuit board etching waste liquid, comprising the steps of:

[0048] (1) Neutralization reaction

[0049] First, the acidic etching waste liquid is added to the alkaline etching waste liquid, and the pH value of the mixed solution is adjusted, and a neutralization reaction occurs between the two to generate basic copper chloride precipitation, and the pH of the mixed solution is 6;

[0050] (2) Pressure filtration separation and pulping

[0051] The mixed liquid after the neutralization reaction is subjected to solid-liquid separation to obtain a liquid phase 1, and then adding water to the basic copper chloride obtained after the reaction to make a slurry to obtain a basic copper chloride slurry, and simultaneously adding water to quicklime to prepare a lime slurry, spare;

[0052] (3) Alkali conversion process

[0053] Then lime slurry is added in the basic copper chloride slurry, stirred to obtain the mixture, the time of the ...

Embodiment 3

[0065] A purification treatment process for circuit board etching waste liquid, comprising the steps of:

[0066] (1) Neutralization reaction

[0067] First, the acidic etching waste liquid is added to the alkaline etching waste liquid, and the pH value of the mixed solution is adjusted, and a neutralization reaction occurs between the two to generate basic copper chloride precipitation, and the pH of the mixed solution is 7;

[0068] (2) Pressure filtration separation and pulping

[0069] The mixed liquid after the neutralization reaction is subjected to solid-liquid separation to obtain a liquid phase 1, and then adding water to the basic copper chloride obtained after the reaction to make a slurry to obtain a basic copper chloride slurry, and simultaneously adding water to quicklime to prepare a lime slurry, spare;

[0070] (3) Alkali conversion process

[0071] Then lime slurry is added in the basic copper chloride slurry, stirred to obtain the mixture, the time of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com