Tubular reaction synthetic method and apparatus for continuously producing acesulfame intermediate

A tubular reaction and synthesis device technology, applied in the preparation of amino compounds from amines, the preparation of sulfuric acid amide, organic chemistry, etc., can solve the problems of long synthesis reaction cycle, poor mass and heat transfer effect, low reaction conversion rate, etc., to achieve The effect of short reaction cycle, low production energy consumption and shortened operation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

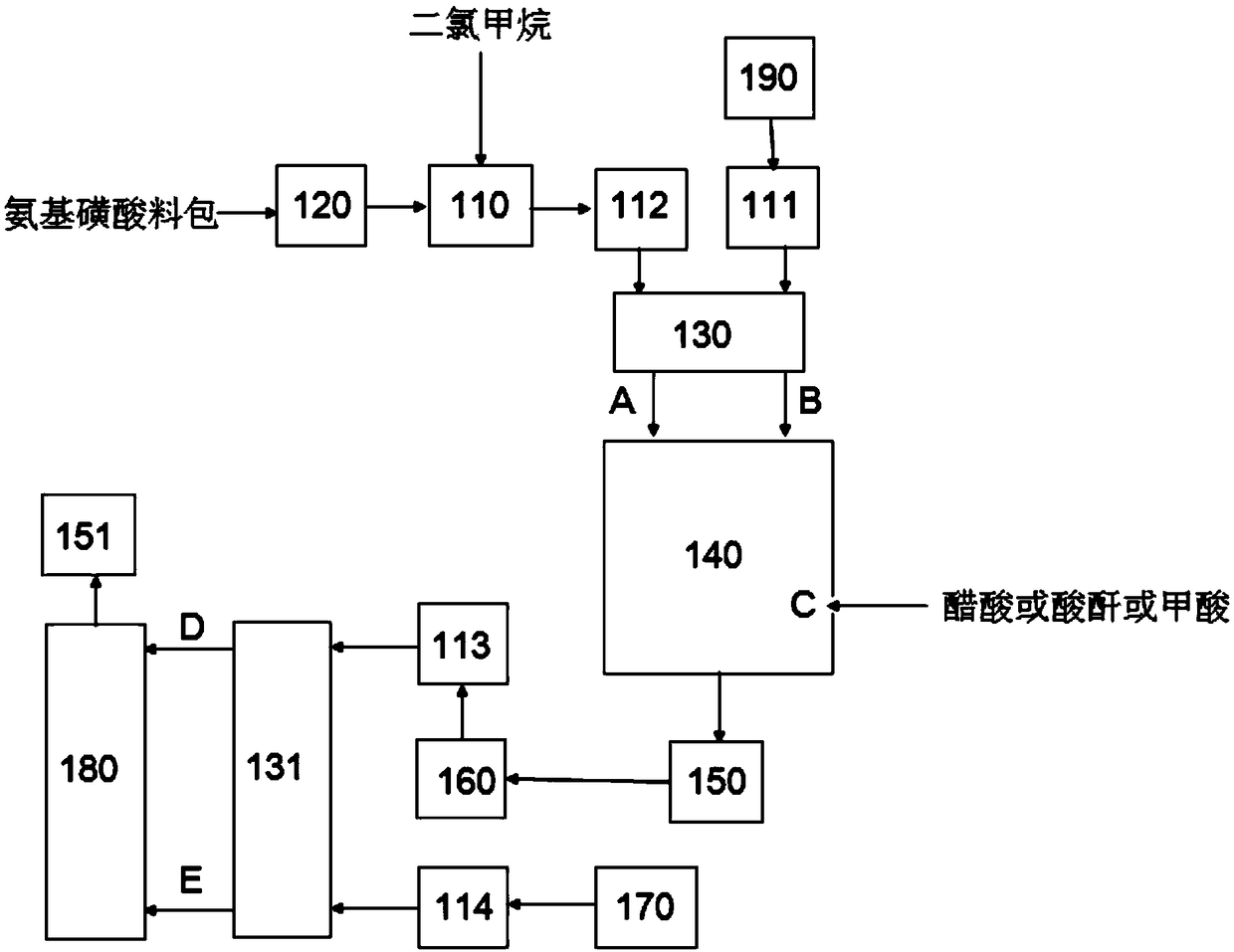

[0022] On the other hand, the present invention proposes a tubular reaction synthesis method for continuous production of acesulfame potassium intermediate, comprising the steps of:

[0023] (1) Dichloromethane is first squeezed into the sulfamic acid mixing tank by a raw material delivery pump and stirred, then the sulfamic acid material bag is dropped into the sulfamic acid mixing tank by the screw propeller, Stir continuously for 0.4h-0.8h, then transfer the evenly stirred sulfamic acid solution into the first metering pump;

[0024](2) Open the jacket shallow cold circulating water valve of the synthesis tubular reactor, and control the temperature of the circulating water by a temperature controller to be 10°C to 15°C, then start the second metering pump and the first metering pump simultaneously pump, the sulfamic acid solution and triethylamine are simultaneously entered into the first pipeline mixer, and enter the synthesis tubular reactor through feed ports A and B re...

specific Embodiment

[0026] (1) Preparation of sulfamic acid solution

[0027] The raw material delivery pump in the tank area pumps methylene chloride into the sulfamic acid sulfamic acid mixing tank R-101A / B (the two are used alternately), starts stirring, and then lifts the flaky sulfamic acid package by the crane , the opening of the material bag is docked with the feeding port of the screw propeller M-101 and put into the sulfamic acid mixing tank at one time through the propeller. There is a special soft connection between the mouth of the sulfamic acid mixing tank and the outlet of the screw propeller. Sulfamic acid The sulphamic acid mixing tank is fully sealed, and the sulphamic acid is in the form of flakes, with a very small amount of dust. The sulfamic acid mixing tank continues to stir for 0.5h, and the uniformly stirred 19% sulfamic acid solution is transferred to the metering tank V-101 by the delivery pump P-101A / B. The organic waste gas volatilized by the sulfamic acid mixing ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com