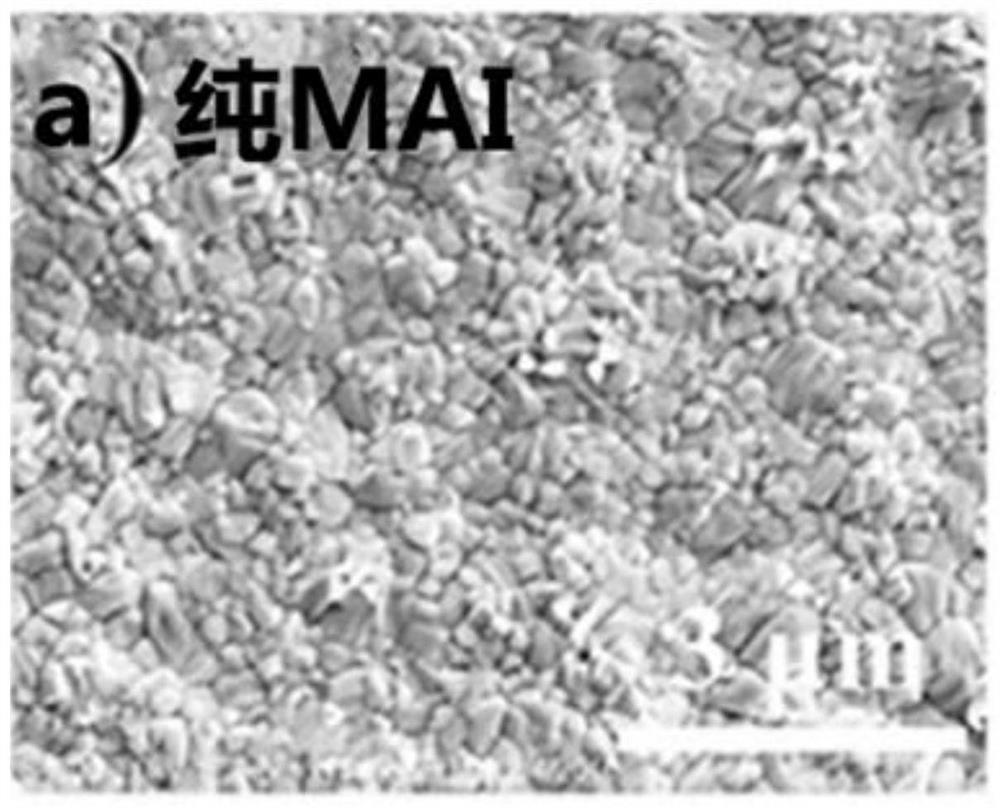

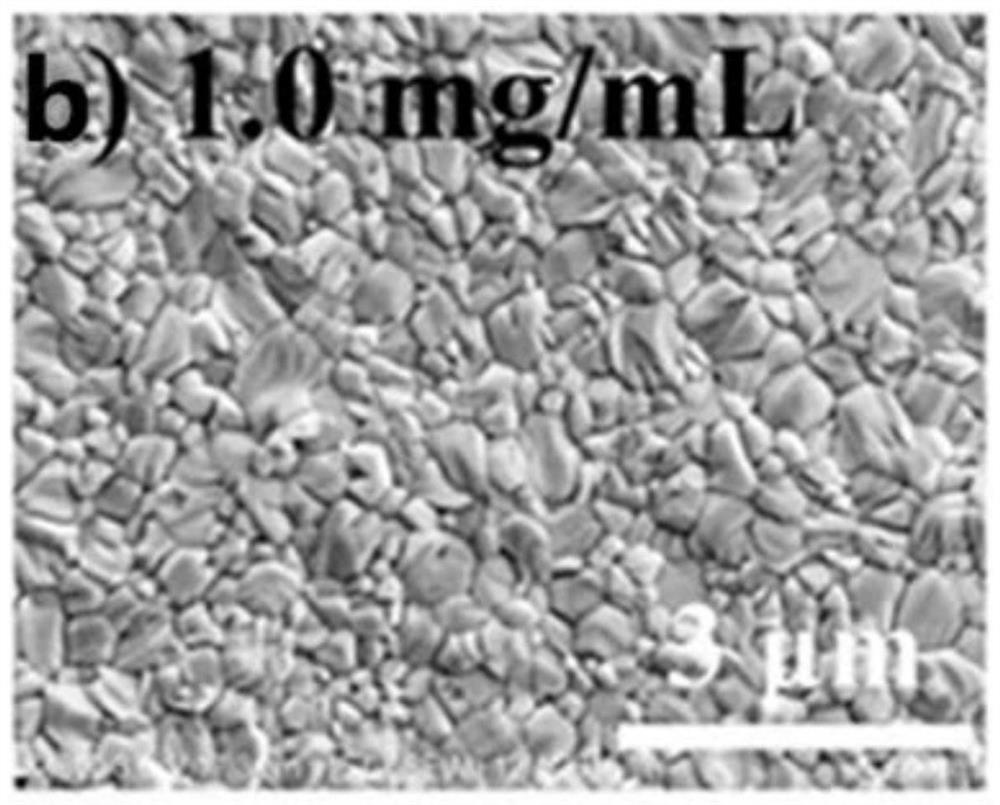

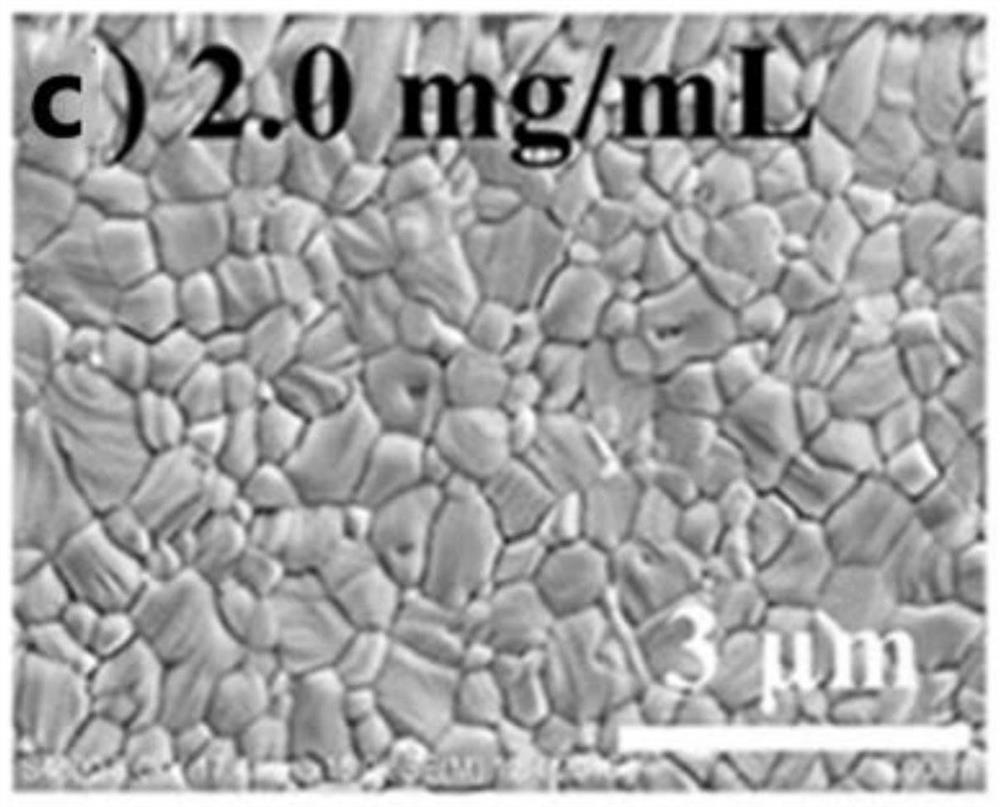

A Preparation Method for Precisely Controlling the Grain Size of Perovskite Thin Films

A grain size, perovskite technology, used in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve problems such as difficulty in monitoring and controlling perovskite grain size, and achieve excellent optoelectronic properties and dense quality. , the effect of uniform grain size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A preparation method for regulating grain growth and size of perovskite film, comprising the following steps:

[0034] (1) Clean the etched ITO (indium tin oxide) conductive glass, then dry it with nitrogen to obtain a clean ITO substrate;

[0035] (2) Preparation of hole transport layer solution doped with F4-TCNQ: add 2,3,5,6-tetrafluoro-7,7',8,8'-tetracyanodi Methyl p-benzoquinone (F4-TCNQ) powder, after stirring evenly, add the IPA solution containing F4-TCNQ to poly[bis(4-phenyl)(2,4,6-trimethylphenyl)amine ] (PTAA) powder, stir evenly to get the hole transport layer solution mixed with F4-TCNQ; wherein, the solid-liquid mass ratio of F4-TCNQ powder and IPA is 0.1wt%, the solid-liquid mass ratio of PTAA powder and IPA The liquid ratio is 5mg / mL;

[0036] (3) Drop the solution configured in step (2) onto the clean ITO substrate obtained in step (1), then evenly glue, and finally put the evenly glued ITO substrate on the hot stage, anneal, and obtain on the ITO sub...

Embodiment 2

[0051] A preparation method for regulating perovskite film grain growth and size, comprising the following steps:

[0052] (1) Clean the etched ITO (indium tin oxide) conductive glass, then dry it with nitrogen to obtain a clean ITO substrate;

[0053] (2) Preparation of the hole transport layer solution mixed with F4-TCNQ: add F4-TCNQ powder to IPA (isopropanol), and after stirring, add the IPA solution containing F4-TCNQ to the PTAA powder , and stir evenly to obtain a hole transport layer solution mixed with F4-TCNQ; wherein, the solid-liquid mass ratio of F4-TCNQ powder and IPA is 0.1wt%, and the solid-liquid ratio of PTAA powder and IPA is 5mg / mL;

[0054] (3) Drop the solution configured in step (2) onto the clean ITO substrate obtained in step (1), then evenly glue, and finally put the evenly glued ITO substrate on the hot stage, anneal, and obtain on the ITO substrate One deck of PTAA:F4-TCNQ thin film, the substrate obtained is recorded as ITO / PTAA:F4-TCNQ;

[0055]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com