Preparation method of functional glycolysis feather meal feed

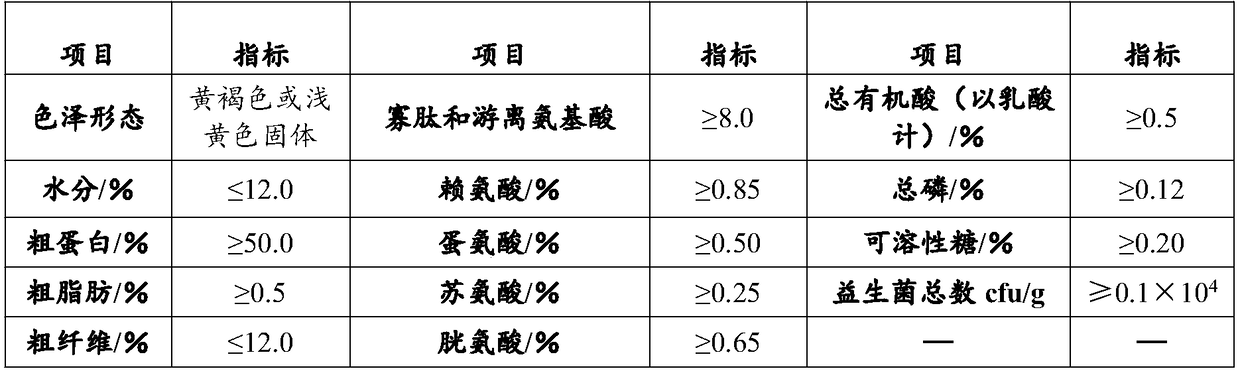

A feather meal and functional technology, applied in the fields of enzyme preparations, microorganisms, and feed, can solve the problems of poor palatability, low digestibility, and low feed intake of feather meal, and achieve good palatability, overcome poor palatability, and anti-nutritional factors The effect of low content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

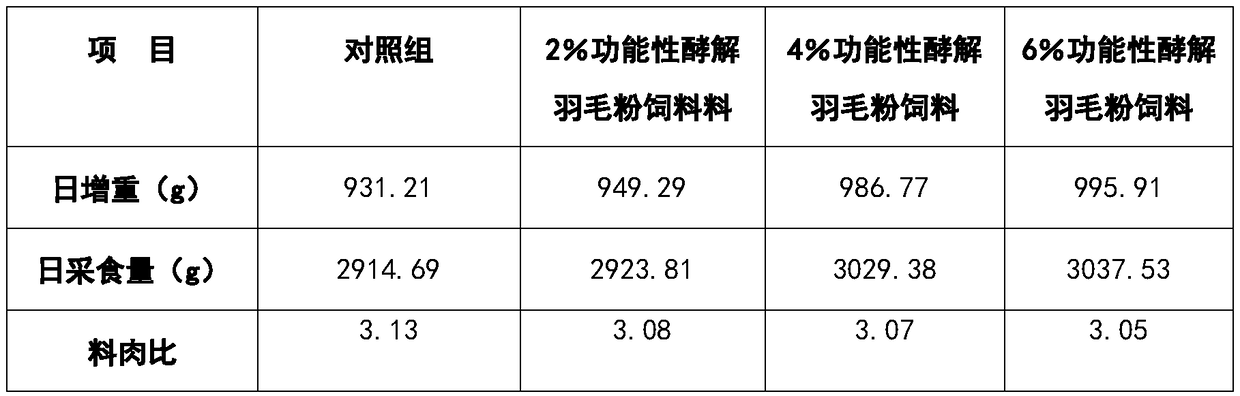

Examples

Embodiment 1

[0052]100kg of feather meal was removed, pulverized, and 15kg of clean water was added to make it evenly tempered, and then high-pressure steam was introduced. Under the conditions of cooking temperature of 150°C and cooking pressure of 400KPa, the cooking time was 2 hours, and 121kg of cooked feather meal wet basis was obtained. (High pressure steam increases moisture 6kg).

[0053] Add 500kg of clean water to 121kg of steamed feather meal wet base to prepare 621kg of feather meal slurry; use 20% sodium hydroxide solution to adjust the pH to 8.6-8.8, add 2.5kg of keratinase, and enzymatically hydrolyze at 50°C Next, liquid enzymatic hydrolysis for 5 hours to obtain 622kg feather powder enzymatic hydrolysis slurry.

[0054] Using plate and frame extrusion, 622kg of feather meal enzymatic hydrolysis slurry was separated from solid and liquid to obtain 577kg of feather meal enzymatic hydrolysis diluent and 45kg of feather meal enzymatic hydrolysis slag wet base; Obtain 110kg fe...

Embodiment 2

[0058] 500kg of feather meal was removed, pulverized, tempered and tempered with 50kg of clean water, and then high-pressure steam was introduced. Under the condition of cooking temperature of 160°C and cooking pressure of 500KPa, the cooking time was 2h, and 570kg of cooked feather meal wet basis was obtained. (High pressure steam increases moisture by 20kg).

[0059] Add 2530kg of clean water to 570kg of steamed feather powder wet base to prepare 3100kg of feather powder slurry; use 20% sodium hydroxide solution to adjust the pH to 8.6-8.8, add 15kg of keratinase, and enzymatically hydrolyze at 60°C , liquid enzymatic hydrolysis for 4 hours, and 3113kg of feather meal was enzymatically hydrolyzed.

[0060] Using plate and frame extrusion, 3113kg of feather powder enzymatic hydrolysis slurry was separated from solid and liquid to obtain 2888kg feather powder enzymatic hydrolysis liquid and 225kg feather powder enzymatic hydrolysis slag wet base; then using evaporation equipme...

Embodiment 3

[0064] 1000kg of feather powder is removed from impurities, crushed, and 80kg of clean water is added to make it evenly tempered, and then high-pressure steam is introduced. Under the conditions of cooking temperature of 150°C and cooking pressure of 400KPa, the cooking time is 1.5h, and 1110kg of cooked feather powder is obtained. Base (high pressure steam increases moisture 30kg).

[0065] Add 6000kg of clean water to 1110kg of steamed feather powder wet base to prepare 7100kg of feather powder slurry; use 20% sodium hydroxide solution to adjust the pH to 8.6-8.8, add 27kg of keratinase, and enzymatically hydrolyze at 60°C , liquid enzymatic hydrolysis for 4 hours, and 7120kg feather powder enzymatic hydrolysis slurry was obtained.

[0066] 7120kg of enzymatic hydrolysis of feather powder is separated from solid and liquid by plate and frame extrusion to obtain 6670kg of enzymatic hydrolysis of feather powder and 450kg of wet base of enzymatic hydrolysis residue of feather p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com