Composite middle layer for performing diffusion bonding on silicon carbide ceramics and bonding process thereof

A composite intermediate layer and silicon carbide ceramic technology, applied in welding equipment, manufacturing tools, metal processing equipment, etc., can solve the problems of joint micro-cracks, large residual stress, mismatching thermal expansion coefficient, etc., achieve high joint connection strength, reduce Effect of thermal expansion coefficient and reduction of residual stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

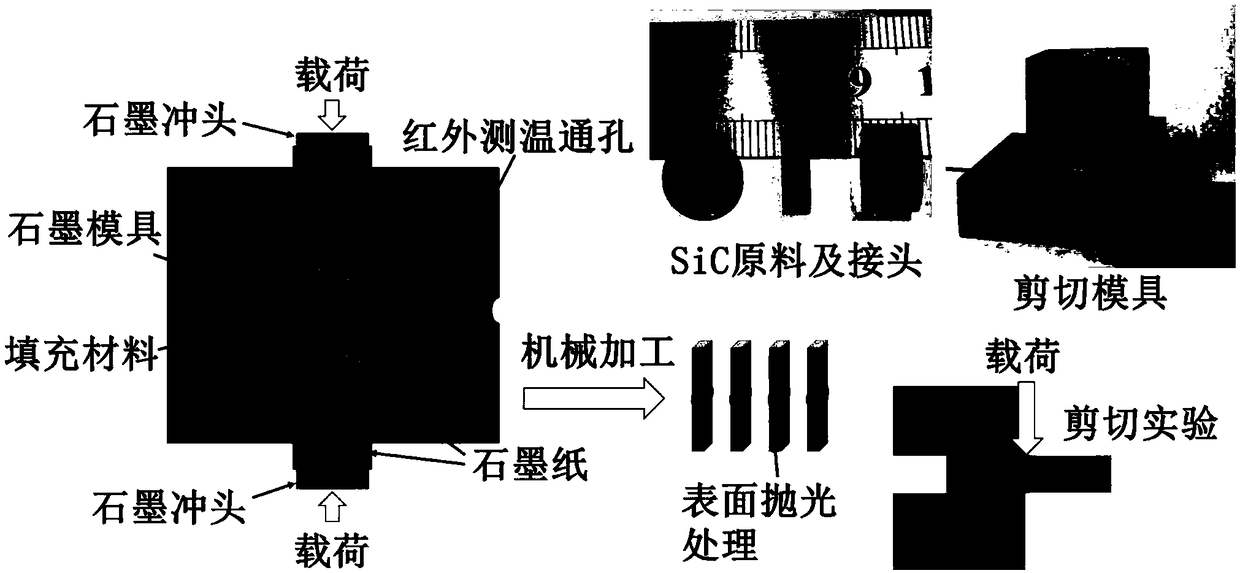

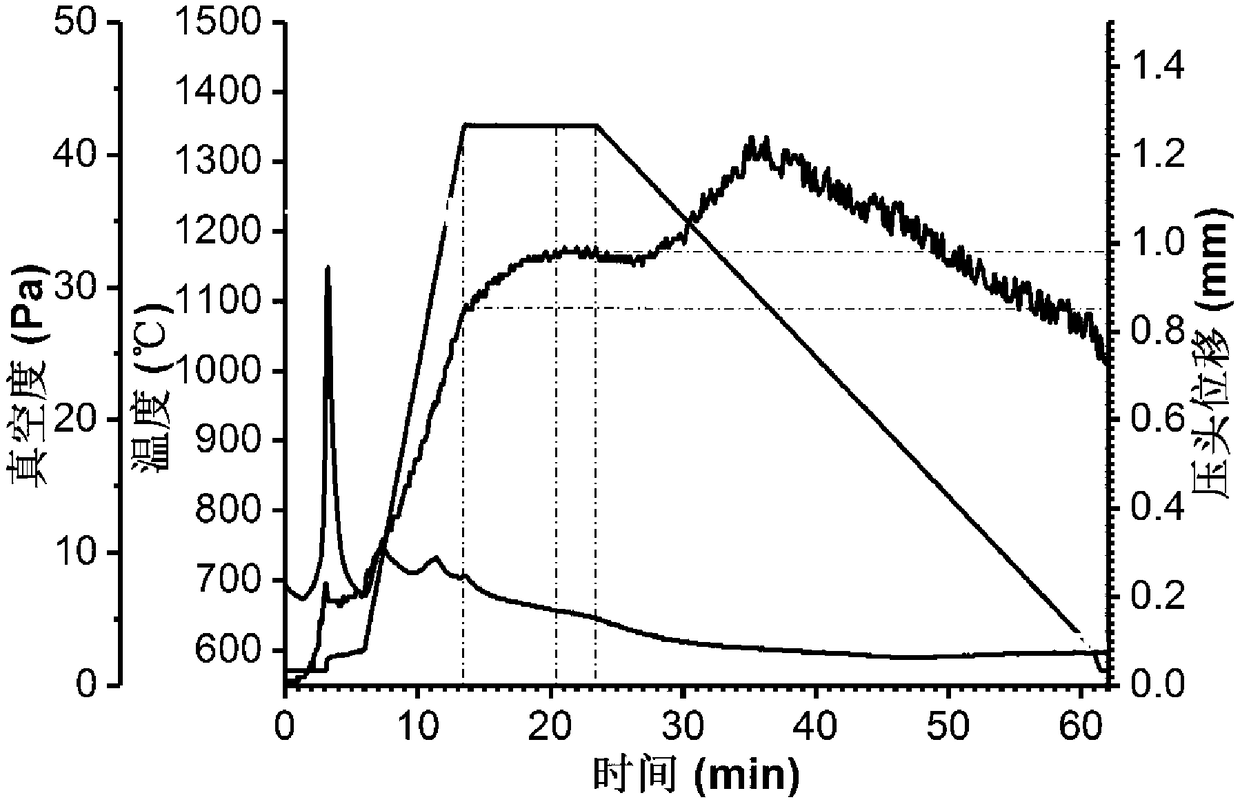

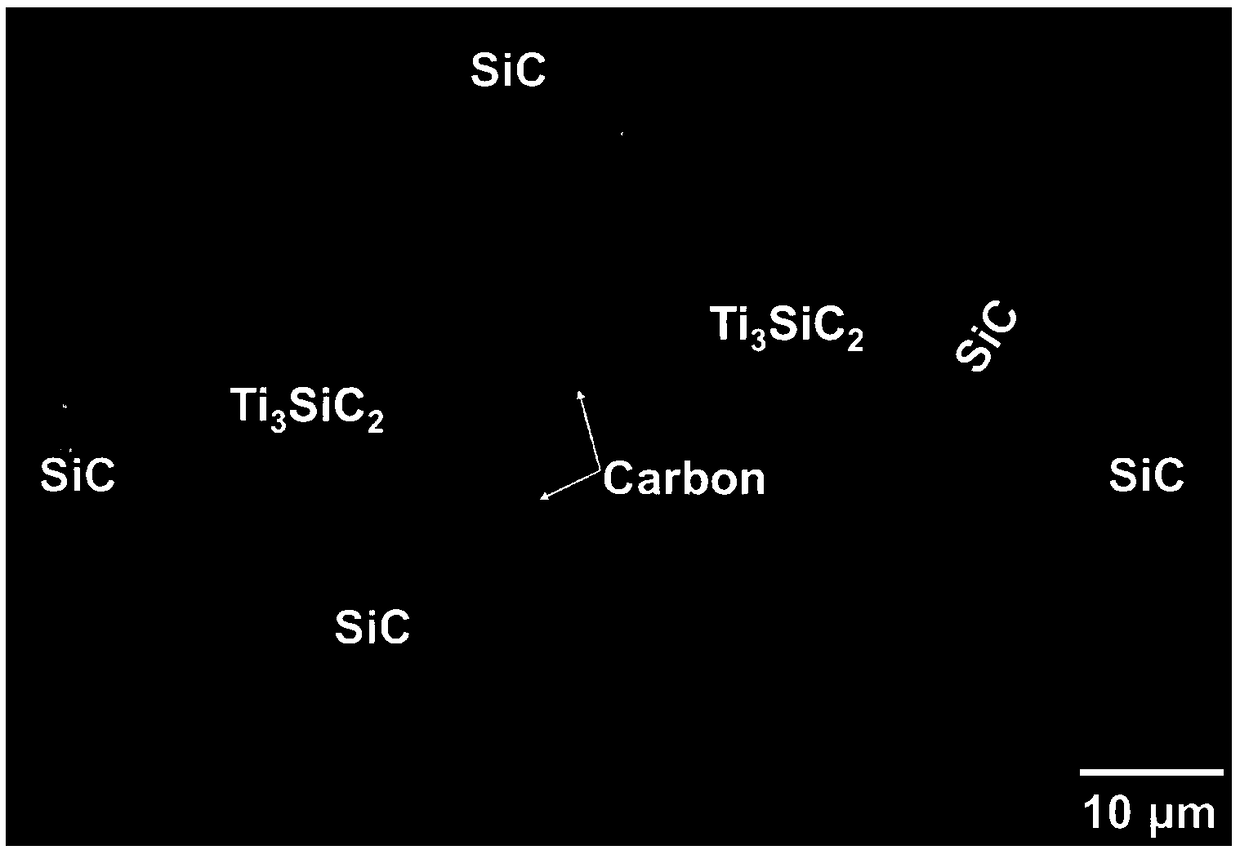

[0039] In this embodiment, the bonding process of the composite intermediate layer diffusion bonding silicon carbide ceramics is as follows:

[0040] 1. Preparation of composite interlayer powder

[0041] With 59.5wt.% titanium hydride powder (TiH 2 ), 24.5wt.% silicon powder (Si), 13.9wt.% graphite powder (C) and 2.1wt.% aluminum powder (Al) are poured into the agate grinding bowl after being mixed as raw materials, with absolute alcohol as the grinding medium, Grind for 1 hour until completely mixed, and then dry in a vacuum oven at 60°C for 6 hours to obtain a composite intermediate layer powder;

[0042] 2. Preparation before welding

[0043] Cylindrical SiC ceramic materials were cut with an internal circle cutting machine Cut into SiC ceramic discs with a thickness of 3 mm, and use 3.5 μm and 1 μm diamond suspension polishing liquid to polish the surface to be welded of the SiC ceramic discs in turn, put the polished SiC ceramic discs into alcohol solution and ultras...

Embodiment 2

[0051] In this embodiment, the bonding process of the composite intermediate layer diffusion bonding silicon carbide ceramics is as follows:

[0052] 1. Preparation of composite interlayer powder

[0053] With 59.5wt.% titanium hydride powder (TiH 2 ), 24.5wt.% silicon powder (Si), 13.9wt.% graphite powder (C) and 2.1wt.% aluminum powder (Al) are poured into the agate grinding bowl after being mixed as raw materials, with absolute alcohol as the grinding medium, Grind for 2 hours until completely mixed, and then dry in a vacuum oven at 60°C for 6 hours to obtain a composite intermediate layer powder;

[0054] 2. Preparation before welding

[0055] Cylindrical SiC ceramic materials were cut with an internal circle cutting machine Cut into SiC ceramic discs with a thickness of 3 mm, and use 3.5 μm and 1 μm diamond suspension polishing liquid to polish the surface to be welded of the SiC ceramic discs in turn, put the polished SiC ceramic discs into alcohol solution and ultra...

Embodiment 3

[0063] In this embodiment, the bonding process of the composite intermediate layer diffusion bonding silicon carbide ceramics is as follows:

[0064] 1. Preparation of composite interlayer powder

[0065] With 59.5wt.% titanium hydride powder (TiH 2 ), 24.5wt.% silicon powder (Si), 13.9wt.% graphite powder (C) and 2.1wt.% aluminum powder (Al) are poured into the agate grinding bowl after being mixed as raw materials, with absolute alcohol as the grinding medium, Grind for 3 hours until completely mixed, and then dry in a vacuum oven at 60°C for 6 hours to obtain a composite intermediate layer powder;

[0066] 2. Preparation before welding

[0067] Cylindrical SiC ceramic materials were cut with an internal circle cutting machine Cut into SiC ceramic discs with a thickness of 3 mm, and use 3.5 μm and 1 μm diamond suspension polishing liquid to polish the surface to be welded of the SiC ceramic discs in turn, put the polished SiC ceramic discs into alcohol solution and ultra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Shear strength | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com