Diatomite-containing plastic packaging film for selectively absorbing ethylene, and preparation method

A technology of diatomite and packaging film, which is applied in the field of plastic packaging film for selectively adsorbing ethylene and its preparation, can solve the problems of poor safety, poor adsorption effect, poor performance, etc. low performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

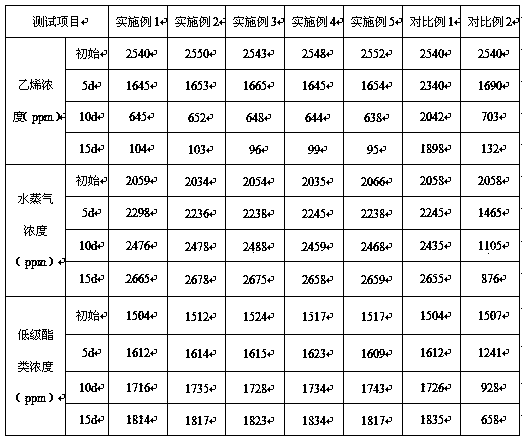

Examples

Embodiment 1

[0030] a. Add cuprous chloride to water to make a dispersion liquid, which is firmly loaded in the pores of diatomite by spray deposition, then mixed with olivine powder, and added to the latex liquid, stirred evenly, and freeze-dried to obtain a network Modified diatomite protected by chemical coating;

[0031] b. Mixing the modified diatomite prepared in step a with the matrix resin of the adsorption layer, heating and melting, and casting to form a film to obtain a thin film of the adsorption layer;

[0032] c. Bonding and compounding the foamed shockproof layer, the porous ultrafiltration membrane, the adsorption layer film, and the PET substrate layer sequentially from bottom to top to prepare a plastic packaging film that selectively adsorbs ethylene.

[0033] In step a, the latex liquid is polyacrylic acid resin latex liquid with a solid content of 25wt%; in step b, the matrix resin of the adsorption layer is polypropylene; the adhesive for bonding and compounding is an...

Embodiment 2

[0037]a. Add cuprous chloride to water to make a dispersion liquid, which is firmly loaded in the pores of diatomite by spray deposition, then mixed with olivine powder, and added to the latex liquid, stirred evenly, and freeze-dried to obtain a network Modified diatomite protected by chemical coating;

[0038] b. Mixing the modified diatomite prepared in step a with the matrix resin of the adsorption layer, heating and melting, and casting to form a film to obtain a thin film of the adsorption layer;

[0039] c. Bonding and compounding the foamed shockproof layer, the porous ultrafiltration membrane, the adsorption layer film, and the PET substrate layer sequentially from bottom to top to prepare a plastic packaging film that selectively adsorbs ethylene.

[0040] In step a, the latex liquid is a polyacrylic resin latex liquid with a solid content of 25wt%; in step b, the matrix resin of the adsorption layer is polyvinyl chloride; the adhesive for bonding and compounding is a...

Embodiment 3

[0044] a. Add cuprous chloride to water to make a dispersion liquid, which is firmly loaded in the pores of diatomite by spray deposition, then mixed with olivine powder, and added to the latex liquid, stirred evenly, and freeze-dried to obtain a network Modified diatomite protected by chemical coating;

[0045] b. Mixing the modified diatomite prepared in step a with the matrix resin of the adsorption layer, heating and melting, and casting to form a film to obtain a thin film of the adsorption layer;

[0046] c. Bonding and compounding the foamed shockproof layer, the porous ultrafiltration membrane, the adsorption layer film, and the PET substrate layer sequentially from bottom to top to prepare a plastic packaging film that selectively adsorbs ethylene.

[0047] In step a, the latex is polyacrylic acid resin latex with a solid content of 25wt%; in step b, the matrix resin of the adsorption layer is polylactic acid; the adhesive for bonding and compounding is an amino resin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com