Environmental-friendly graphene high-weather-resistance automobile aqueous coating and preparation method thereof

A water-based coating and graphene technology, applied in the direction of anti-corrosion coatings, coatings, etc., can solve the problems of weather resistance that cannot meet the needs of use, achieve excellent mechanical strength, reduce cracking and peeling, and reduce wear and tear effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

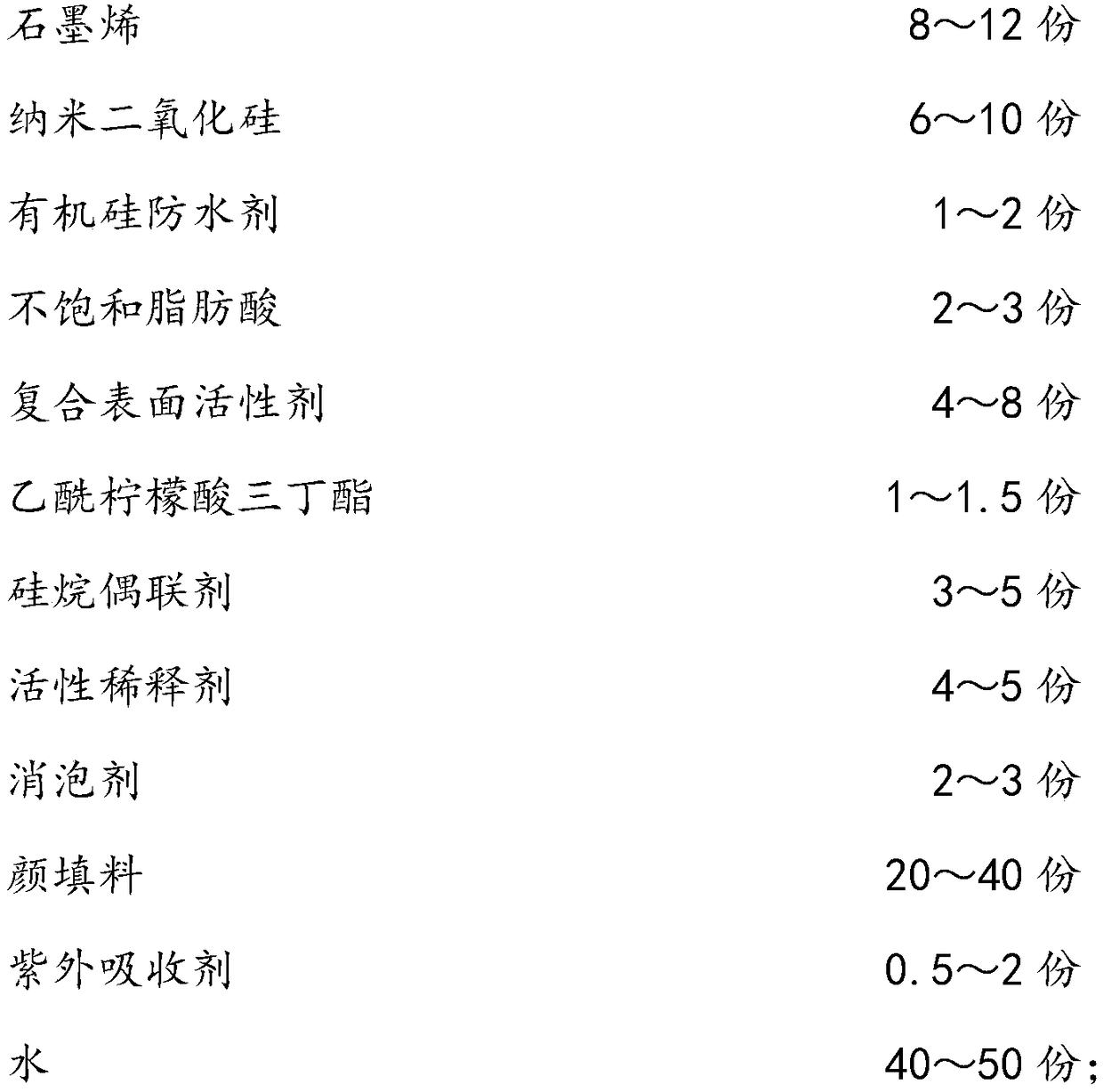

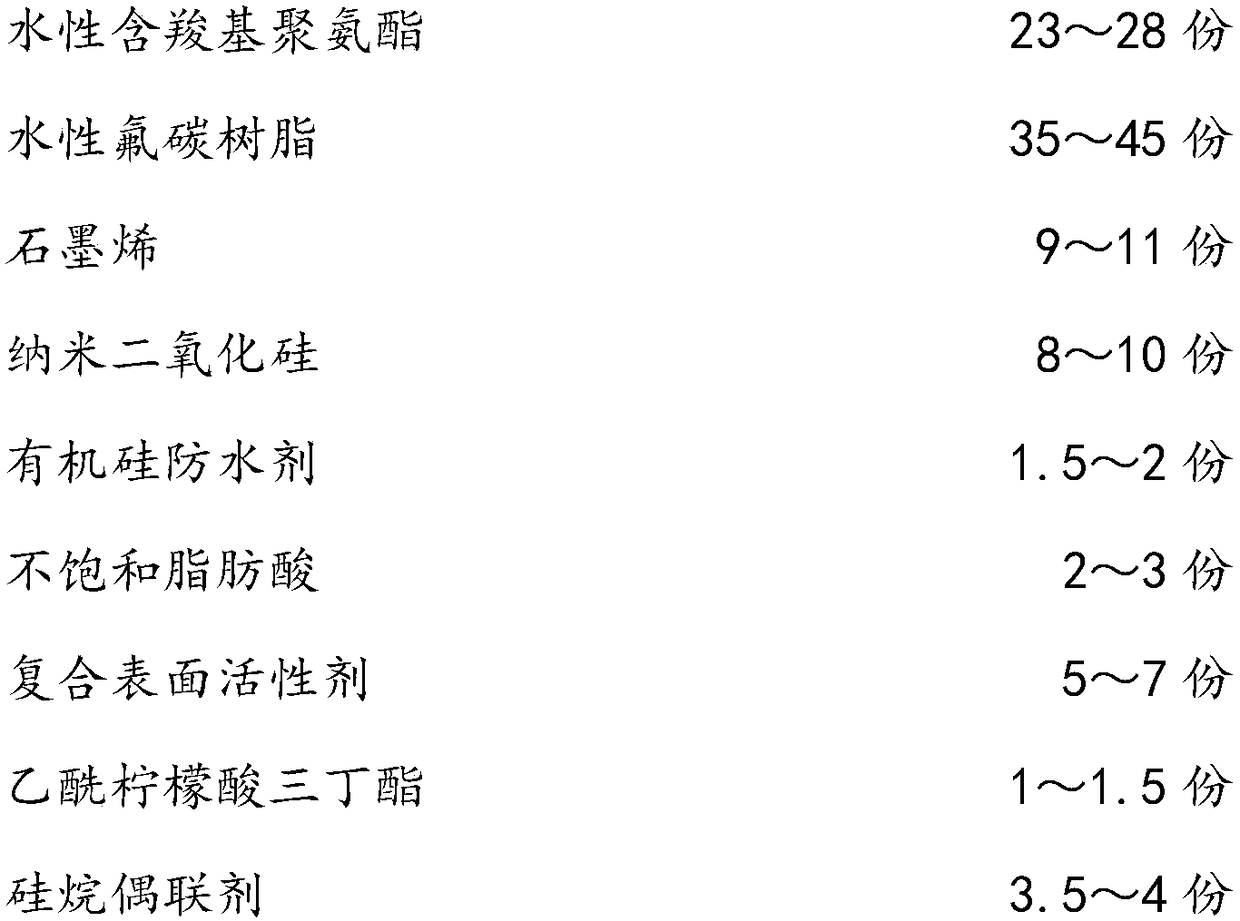

Method used

Image

Examples

Embodiment 1

[0038]Step 1. Add 25 parts of water-based carboxyl-containing polyurethane, 38 parts of water-based fluorocarbon resin and 43 parts of water into the stirring equipment, heat up to 120°C, stir at 600 rpm for 70 minutes, and add 8.6 parts of nano Silica and 2 parts of unsaturated fatty acids;

[0039] Step 2: On the basis of step 1, add 5.3 parts of composite surfactant, 3.6 parts of silane coupling agent, 4.5 parts of reactive diluent, 2.1 parts of defoamer, 28 parts of pigments and fillers, and stir for 95 minutes at a speed of 1000 rpm , then add 1.2 parts of acetyl tributyl citrate, cool down to 80°C, and continue to stir for 45 minutes;

[0040] Step 3. Disperse 9 parts of graphene and add it to the product of Step 2 after ultrasonic vibration, then add 1.8 parts of silicone water repellent and 0.8 parts of UV absorber, heat up to 95°C, and stir at a rate of 1000 rpm After 65 minutes, cool down and filter to obtain the first component of the environmentally friendly graph...

Embodiment 2

[0043] Step 1. Add 25 parts of water-based carboxyl-containing polyurethane, 39 parts of water-based fluorocarbon resin and 44 parts of water into the stirring equipment, raise the temperature to 120°C, stir at 600 rpm for 70 minutes, and add 9.5 parts of nano Silica and 2.3 parts of unsaturated fatty acids;

[0044] Step 2: On the basis of step 1, add 6.1 parts of composite surfactant, 3.5 parts of silane coupling agent, 4.2 parts of active diluent, 2.6 parts of defoamer, 31 parts of pigments and fillers, and stir at a speed of 1000 rpm for 95 minutes , then add 1.2 parts of acetyl tributyl citrate, cool down to 80°C, and continue to stir for 45 minutes;

[0045] Step 3. Disperse 9 parts of graphene and add it to the product of Step 2 after ultrasonic vibration, then add 1.6 parts of silicone water repellent and 1.2 parts of UV absorber, heat up to 95°C, and stir at a rate of 1000 rpm After 65 minutes, cool down and filter to obtain the first component of the environmentally...

Embodiment 3

[0048] Step 1. Add 26 parts of water-based carboxyl-containing polyurethane, 43 parts of water-based fluorocarbon resin and 48 parts of water into the stirring equipment, raise the temperature to 120°C, stir at 600 rpm for 70 minutes, and add 9.6 parts of nano Silica and 2.6 parts of unsaturated fatty acids;

[0049] Step 2: On the basis of step 1, add 6.5 parts of composite surfactant, 3.8 parts of silane coupling agent, 4.3 parts of active diluent, 2.8 parts of defoamer, 35 parts of pigments and fillers, and stir for 95 minutes at a speed of 1000 rpm , then add 1.5 parts of acetyl tributyl citrate, cool down to 80°C, and continue stirring for 45 minutes;

[0050] Step 3, disperse 10.5 parts of graphene, add it to the product of step 2 after ultrasonic vibration, then add 1.9 parts of silicone waterproofing agent, 1.2 parts of ultraviolet absorber, heat up to 95 ° C, and stir at a rate of 1000 rpm After 65 minutes, cool down and filter to obtain the first component of the en...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| electron mobility | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com