Preparation method of grapefruit-honey alcoholic drink

A grapefruit and honey technology, which is applied in the preparation of alcoholic beverages, microorganism-based methods, biochemical equipment and methods, etc., can solve the problems of too strong fermentation taste of wine body, single preparation process, insufficient mellow wine body, etc. Good wine stability, low sugar content, pure and full-bodied wine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

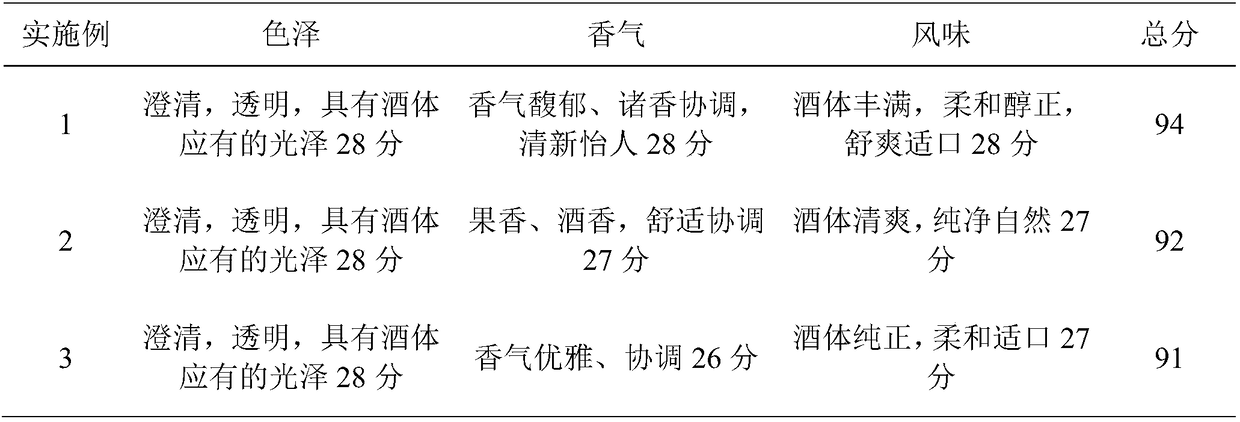

Embodiment 1

[0020] (1) Preparation of grapefruit juice: select fresh grapefruit, clean the peel with water, peel, remove seeds, squeeze the juice, and set aside;

[0021] (2) Pretreatment of grapefruit juice: Add 2‰ pectinase to decompose pectin and cellulose at 37°C for 3 hours, filter, and set aside;

[0022] (3) Preparation of grapefruit honey distilled wine: Weigh 12 parts of honey, 88 parts of grapefruit juice, add 0.2% wine Saccharomyces cerevisiae, and carry out low-temperature fermentation at a temperature of 21°C. When the change is the end of the fermentation, then the fermented liquid is distilled, the distillation pressure is 0.2Mpa, and the alcohol content of the distilled wine is 45% vol, for subsequent use;

[0023] (4) Preparation of combined base wine: 35 parts of distilled wine in (3), 45 parts of edible alcohol, 20 parts of Yanghe Daqu celadon (42% vol), according to the above proportions, in the aseptic operation room at 15-20°C, Blend at low temperature to make a com...

Embodiment 2

[0029] (1) Preparation of grapefruit juice: select fresh grapefruit, clean the peel with water, peel, remove seeds, squeeze the juice, and set aside;

[0030] (2) Pretreatment of grapefruit juice: Add 2‰ of pectinase to decompose pectin and cellulose at 36.5°C for 3.5 hours, filter and set aside;

[0031] (3) Preparation of grapefruit honey distilled wine: Weigh 14 parts of honey, 86 parts of grapefruit juice, add 0.25% wine Saccharomyces cerevisiae, and carry out low-temperature fermentation at a temperature of 22°C. When the change is the end of the fermentation, then the fermented liquid is distilled, the distillation pressure is 0.2Mpa, and the alcohol content of the distilled wine is 46% vol, for subsequent use;

[0032] (4) Preparation of combined base wine: 36 parts of distilled wine in (3), 47 parts of edible alcohol, 17 parts of Yanghe Daqu celadon (42% vol), according to the above proportions, in the aseptic operation room at 15-20°C, Blend at low temperature to mak...

Embodiment 3

[0038] (1) Preparation of grapefruit juice: select fresh grapefruit, clean the peel with water, peel, remove seeds, squeeze the juice, and set aside;

[0039] (2) Pretreatment of grapefruit juice: add 2‰ pectinase to decompose pectin and cellulose at 36°C for 4 hours, filter, and set aside;

[0040] (3) Preparation of grapefruit honey distilled wine: Weigh 15 parts of honey, 85 parts of grapefruit juice, add 0.3% of Saccharomyces cerevisiae, and carry out low-temperature fermentation at a temperature of 23°C. When the change is the end of the fermentation, then the fermented liquid is distilled, the distillation pressure is 0.2Mpa, and the alcohol content of the distilled wine is 47% vol, for subsequent use;

[0041] (4) Preparation of combined base wine: 37 parts of distilled wine in (3), 48 parts of edible alcohol, 15 parts of Yanghe Daqu celadon (42% vol), according to the above proportions, in the aseptic operation room at 15-20°C, Blend at low temperature to make a combi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com