Aqueous PVDF coated lithium ion battery diaphragm and preparation method thereof

A lithium-ion battery, water-based technology, applied in the preparation of lithium-ion battery separators, and in the field of water-based PVDF-coated lithium-ion battery separators, can solve the problem of poor adhesion, easy blockage of ion channels, uneven size of islands, etc. problem, achieve the effect of improving the process capability, improving the positive and negative interface of the battery cell, and increasing the air permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

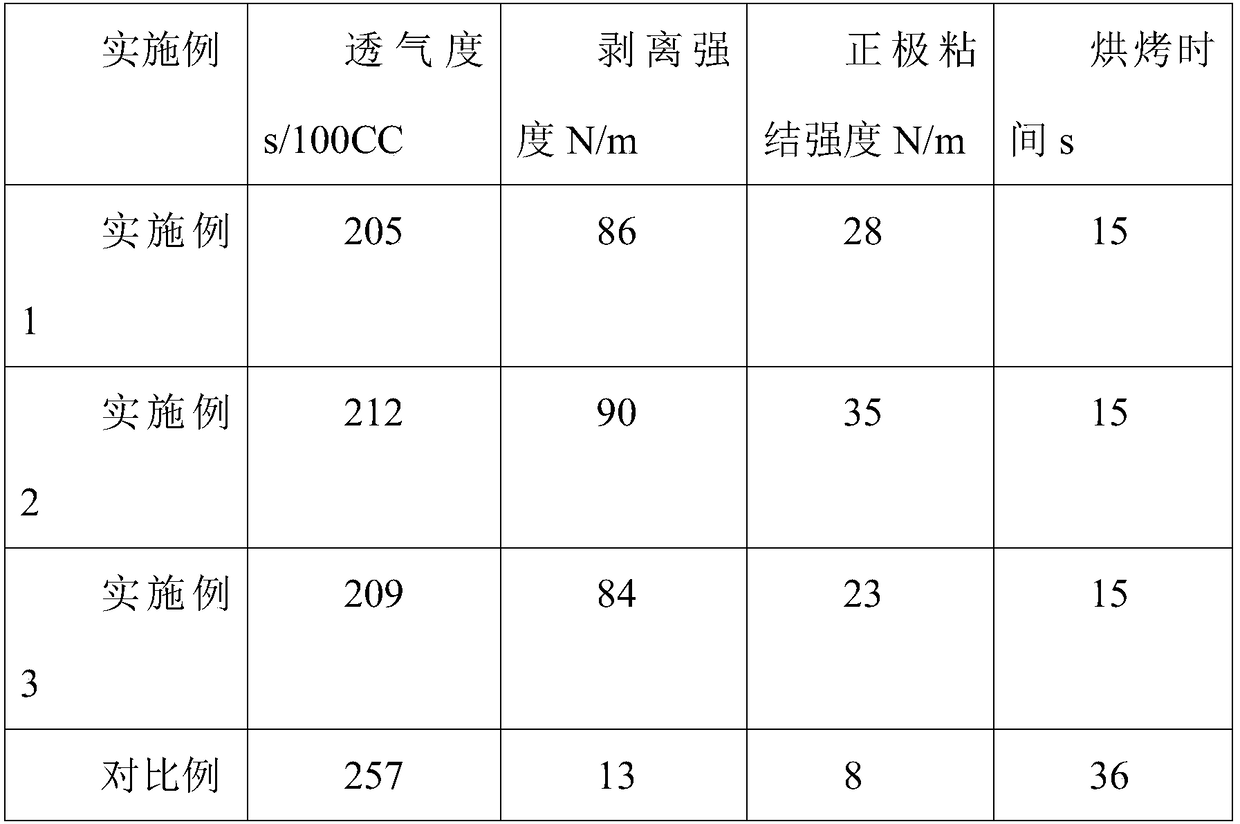

Embodiment 1

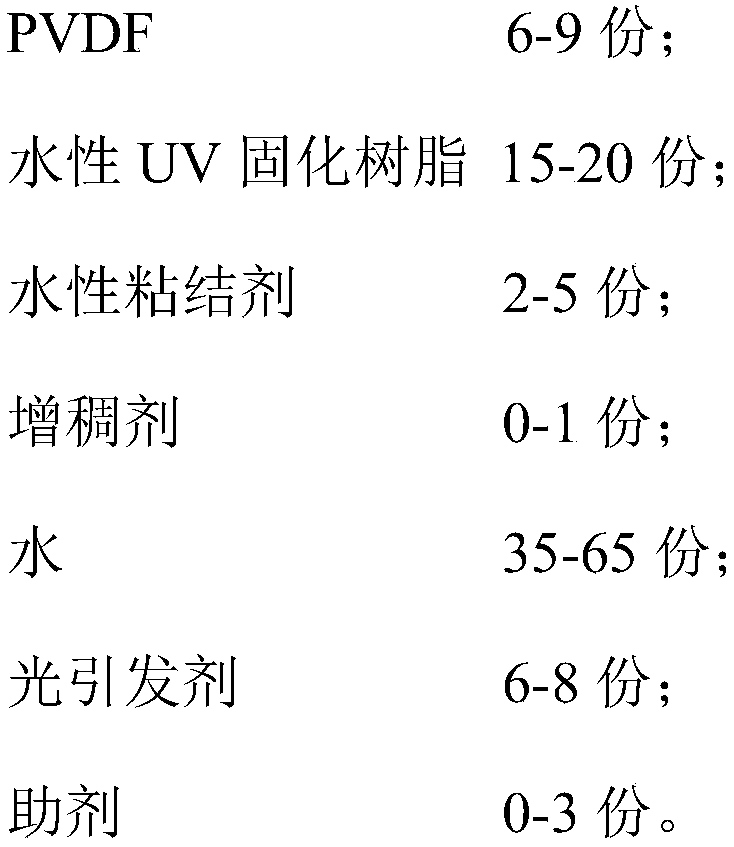

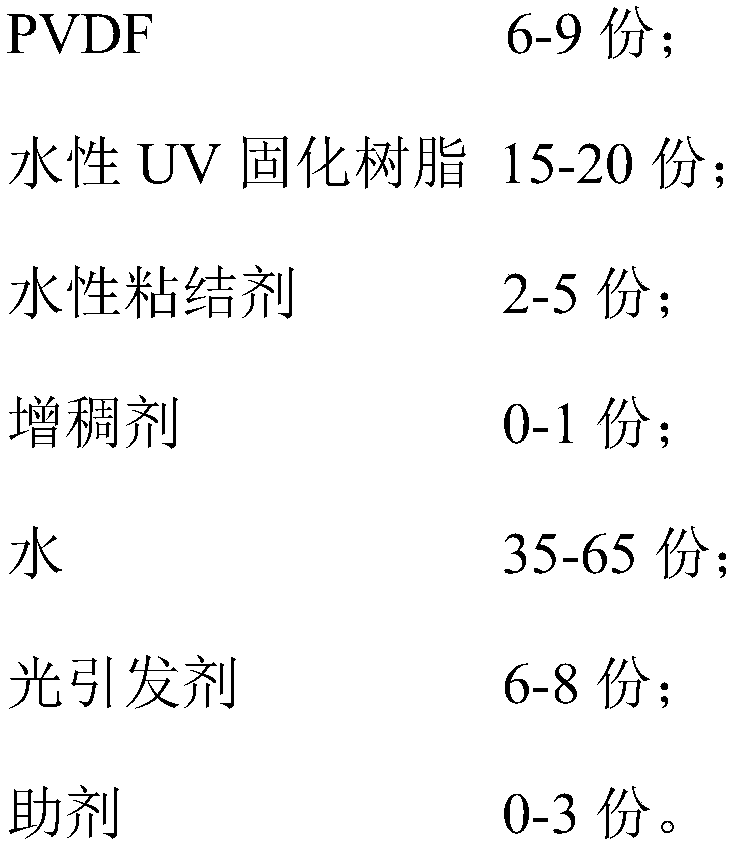

[0024] A lithium-ion battery diaphragm coated with water-based PVDF of the present invention is composed of a lithium-ion battery base film and a coating on one or both sides of the base film, the coating is composed of PVDF slurry, and the PVDF slurry The composition and mass parts are: PVDF is 9 parts of polyvinylidene fluoride copolymer; water-based UV curable resin is preferably 15 parts of UP resin; water-based binder is preferably 4 parts of acrylic polymer; thickener is carboxymethyl Base cellulose is preferably 0.6 parts; water is 63 parts; photoinitiator is preferably benzophenone, preferably 7 parts; auxiliary agent is 0.09 parts of dispersant, and 1 part of polymerization inhibitor.

[0025] Among them, the polyvinylidene fluoride copolymer of PVDF has a molecular weight of 500,000-800,000 and a particle size of 150nm-300nm.

[0026] The lithium-ion battery base film is a polyethylene film with a thickness of 5um and a porosity of 36%.

[0027] A preparation method...

Embodiment 2

[0032] A lithium-ion battery diaphragm coated with water-based PVDF of the present invention is composed of a lithium-ion battery base film and a coating on one or both sides of the base film, the coating is composed of PVDF slurry, and the PVDF slurry The composition and mass parts are: PVDF is 8 parts of polyvinylidene fluoride copolymer; the water-based UV curable resin is preferably 17 parts of PUA resin; the water-based binder is preferably 5 parts of acrylic polymer; the thickener is methylol The base cellulose is preferably 0.8 parts; the water is 60 parts; the photoinitiator is preferably a carbonyl compound, preferably 8 parts; the auxiliary agent is 0.09 parts of a dispersant, and the polymerization inhibitor is 2 parts.

[0033] The PVDF is a polyvinylidene fluoride copolymer with a molecular weight of 500,000-800,000 and a particle size of 150nm-300nm.

[0034] The lithium ion battery base film is a polypropylene film with a thickness of 15um and a porosity of 40%....

Embodiment 3

[0040] A lithium-ion battery diaphragm coated with water-based PVDF of the present invention is composed of a lithium-ion battery base film and a coating on one or both sides of the base film, the coating is composed of PVDF slurry, and the PVDF slurry The composition and mass parts are: PVDF is polyvinylidene fluoride copolymer, 6 parts; water-based UV curing resin is EA resin, preferably 15 parts; water-based binder is acrylic polymer, preferably 2 parts; thickener is attapulgite Clay is preferably 1 part; water is 65 parts; photoinitiator is preferably azo compound, preferably 6 parts; auxiliary agent is 0.09 parts of dispersant, and polymerization inhibitor is 2.5 parts.

[0041] The lithium-ion battery base film is a polyimide film with a thickness of 25um and a porosity of 45%.

[0042] A preparation method of a water-based PVDF-coated lithium-ion battery diaphragm, the preparation steps of which are: a. Add the dispersant and attapulgite clay in the auxiliary agent to 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com