Transitional metal/sulfur/nitrogen co-doped carbon composite material used for fuel cell electrocatalyst and preparation method of composite material

A technology of carbon composite materials and transition metals, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of complicated preparation methods and unfavorable large-scale production of catalysts, and achieve the effect of improving catalytic activity and stability and improving dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] 1. Ultrasonically disperse 2g of carbon black in 250mL of water in a single-necked flask to obtain a black slurry;

[0030] 2. Add 1.6g of imidazole to the above slurry, and ultrasonically dissolve;

[0031] 3. Add 2mol of Fe(SCN) to the above flask 3 , Ultrasonic dissolution to obtain a uniform feed liquid;

[0032] 4. Put the above liquid into an oven at 100°C to dry to obtain dry powder;

[0033] 5. Put the above powder into a tube furnace, heat-treat at 700°C for 2 hours under a nitrogen atmosphere, and cool to room temperature to obtain a black powder;

[0034] 6. Soak the product obtained by the above heat treatment in 2mol / L sulfuric acid solution at 100°C for 8 hours, then wash with water until neutral, and dry;

[0035] 7. Put the above product into a tube furnace, heat-treat at 700° C. for 2 hours under a nitrogen atmosphere, and cool to room temperature to obtain the final catalyst.

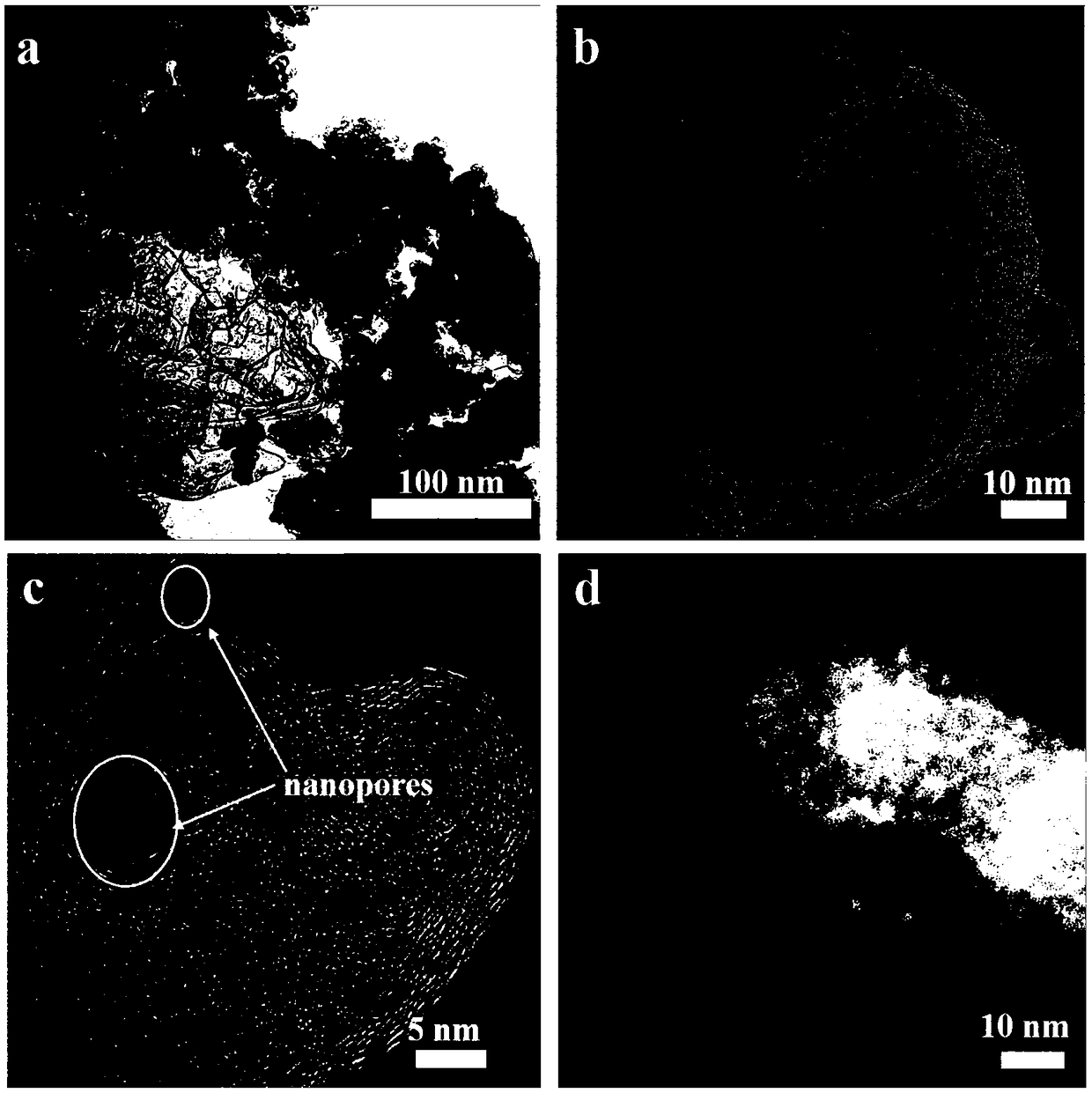

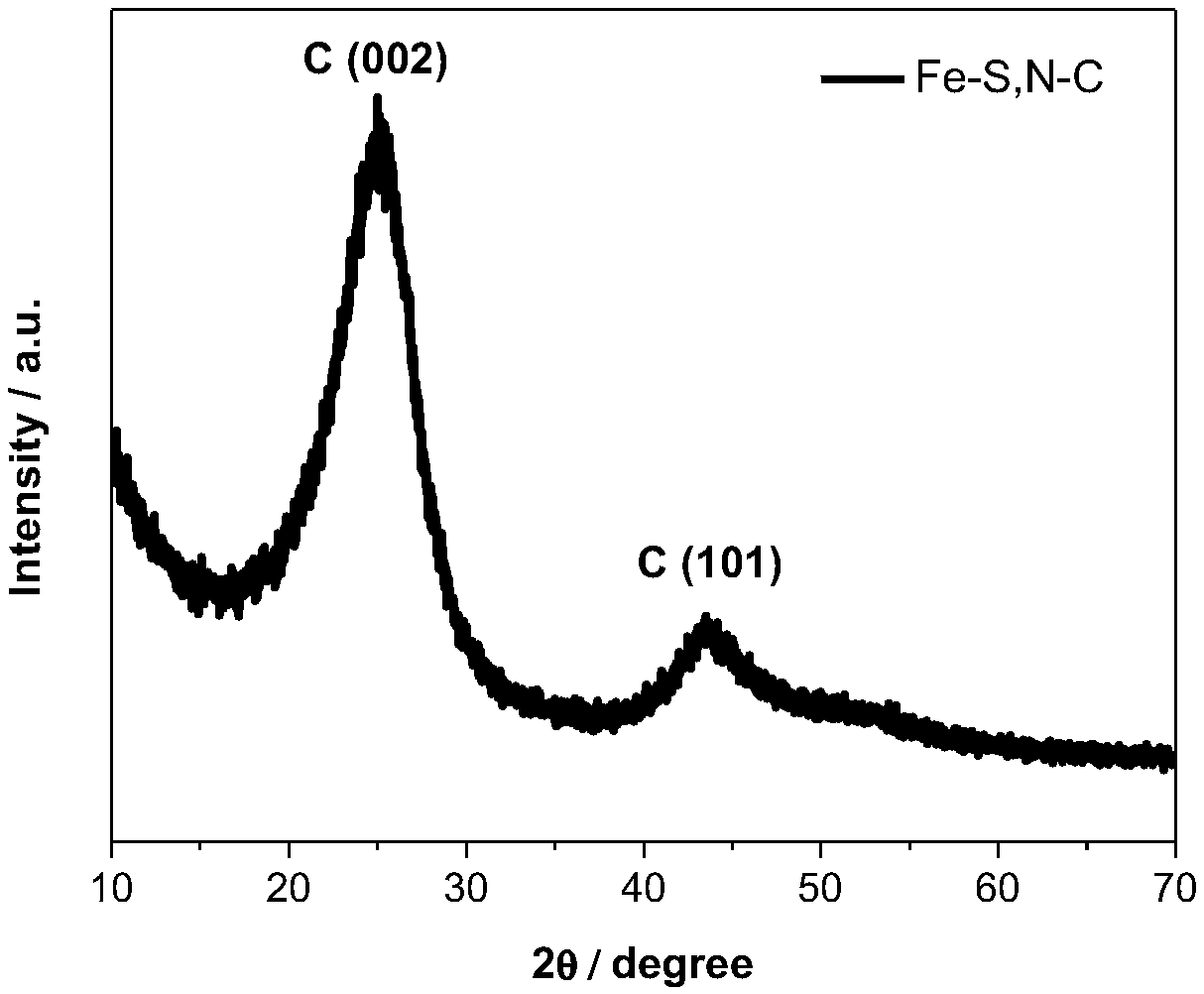

[0036] Catalyst TEM that present embodiment obtains, EDS and XRD such a...

Embodiment 2

[0038] 1. Ultrasonic disperse 1 g of carbon nanotubes in 500 mL of water in a single-necked flask to obtain a black slurry;

[0039] 2. Add 5g of melamine to the above slurry and dissolve it ultrasonically;

[0040] 3. Add 1mol of Co(SCN) to the above flask 2 , Ultrasonic dissolution to obtain a uniform feed liquid;

[0041] 4. Put the above liquid into an oven at 80°C to dry to obtain dry powder;

[0042] 5. Put the above powder into a tube furnace, heat-treat at 900°C for 4 hours under a nitrogen atmosphere, and cool to room temperature to obtain a black powder;

[0043] 6. Soak the product obtained by the above heat treatment in a 3mol / L hydrochloric acid solution and treat it at 80°C for 12 hours, then wash it with water until neutral, and dry it;

[0044] 7. Put the above product into a tube furnace, heat-treat at 900° C. for 4 hours under a nitrogen atmosphere, and cool to room temperature to obtain the final catalyst.

[0045] Catalyst TEM that present embodiment ob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com