Formaldehyde-removing activated carbon/bacterial cellulose composite filler and preparation method thereof

A bacterial cellulose and composite filler technology, applied in the field of air purification, can solve the problems of easy blockage of pores, poor adsorption capacity, easy desorption of adsorbed gas, etc., and achieve the effect of preventing foaming collapse, preventing pore blockage, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

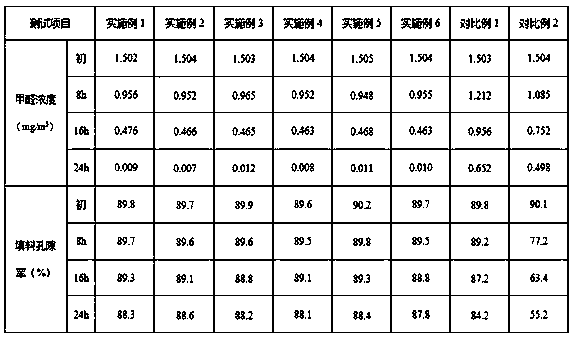

Examples

Embodiment 1

[0029] (1) Add activated carbon to zinc chloride solution, place it in a reaction kettle, activate at high temperature, filter, wash, and dry to obtain activated activated carbon; the mass concentration of zinc chloride solution is 36%; the activation temperature is 720°C , the time is 2.5h;

[0030] (2) Add the activated activated carbon prepared in step (1) into the toluene solution of organosilicon and aminopyridine, stir under the protection of nitrogen, and heat to reflux, then filter, wash and dry to obtain aminated activated carbon; organosilicon It is vinyltriethoxysilane; aminopyridine is 2-aminopyridine; in the toluene solution of organic silicon and aminopyridine, there are 7 parts by weight of organic silicon, 26 parts by weight of aminopyridine and 67 parts by weight of toluene;

[0031] (3) Dissolve the bacterial cellulose in the aqueous solution of sodium hydroxide / urea, deposit it on the surface of the aminated activated carbon prepared in step (2) by spray dry...

Embodiment 2

[0036] (1) Add activated carbon to zinc chloride solution, place it in a reaction kettle, activate at high temperature, filter, wash, and dry to obtain activated activated carbon; the mass concentration of zinc chloride solution is 30%; the activation temperature is 600°C , the time is 3h;

[0037] (2) Add the activated activated carbon prepared in step (1) into the toluene solution of organosilicon and aminopyridine, stir under the protection of nitrogen, and heat to reflux, then filter, wash and dry to obtain aminated activated carbon; organosilicon It is vinyltrimethoxysilane; aminopyridine is 3-aminopyridine; in the toluene solution of organic silicon and aminopyridine, there are 5 parts by weight of organic silicon, 20 parts by weight of aminopyridine and 75 parts by weight of toluene;

[0038] (3) Dissolve the bacterial cellulose in the aqueous solution of sodium hydroxide / urea, deposit it on the surface of the aminated activated carbon prepared in step (2) by spray dryi...

Embodiment 3

[0041] (1) Add activated carbon to zinc chloride solution, place it in a reaction kettle, activate at high temperature, filter, wash, and dry to obtain activated activated carbon; the mass concentration of zinc chloride solution is 40%; the activation temperature is 800°C , the time is 2h;

[0042](2) Add the activated activated carbon prepared in step (1) into the toluene solution of organosilicon and aminopyridine, stir under the protection of nitrogen, and heat to reflux, then filter, wash and dry to obtain aminated activated carbon; organosilicon It is vinyl tris (β-methoxyethoxy) silane; aminopyridine is 4-aminopyridine; in the toluene solution of organic silicon and aminopyridine, there are 10 parts by weight of organic silicon, 30 parts by weight of aminopyridine and 60 parts by weight of toluene;

[0043] (3) Dissolve the bacterial cellulose in the aqueous solution of sodium hydroxide / urea, deposit it on the surface of the aminated activated carbon prepared in step (2)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com