a water filter stick

A water filtration and water source technology, which is applied in filtration treatment, other chemical processes, water/sewage treatment, etc., can solve the problems of limited use and wide application of activated carbon fibers, and achieve convenient and fast filtration, broad application prospects, and preparation conditions. mild effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0053] Preparation method of ascorbic acid chrose polyammonium salt is:

[0054] I. Add the chitosan to N-methylpyrrolidone, at 30 ° C for 10 h at 30 ° C, sodium iodide, 1 mol / L, sodium hydroxide, iodide, and keep the rotation speed, 55 ° C The reaction was continued for 24 h, the chitosan, N-methylpyrrolidone, sodium iodide, aqueous sodium hydroxide, and the mass ratio of iodide 1: 50: 2: 8: 11, then add chitosan mass 155 times The acetone is precipitated, filtered, the resulting filter was placed at 50 ° C for 50 h to give N, N, N-trimethyl chitosan quaternan quaternary ammonium salt;

[0055] II. The mass ratio of 1: 18 (g / mL) is added to the N, N, N-trimethyl chitosanium salt, and 18% by weight of the sodium-critical solution of sodium sodium is added, at 30 ° C, 400R / min. The mixture was stirred under conditions for 20 min, and the resulting mixture was poured into the dialysis bag, and the port of the dialysis bag was died, followed by placing the dialysis bag with a l...

Embodiment 1

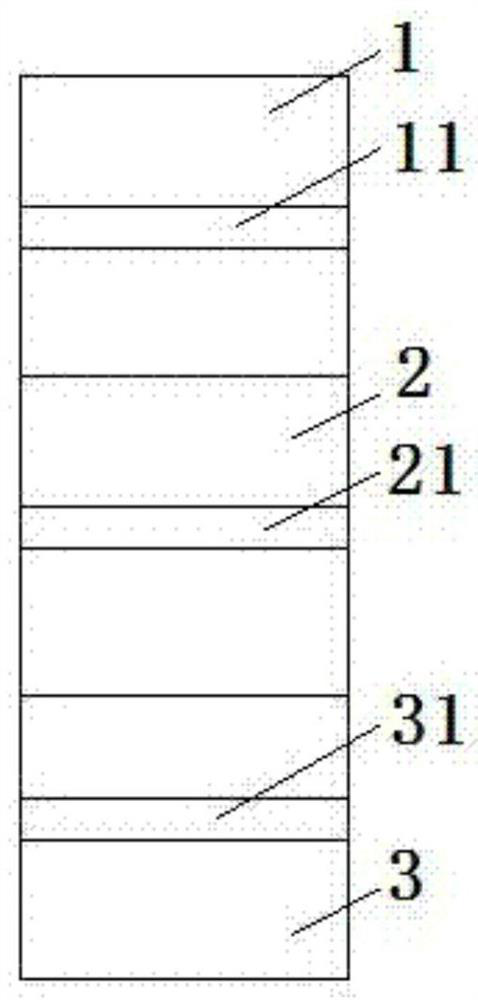

[0062] like figure 1 As shown, a water filter rod comprising a first tube 1, a second tube 2, and a third tube 3, a first tube 1, a second tube 2, and a third tube 3 sequentially connected by a threaded seal. The nano filter element 11 is provided in the first tube 1, and the second tube 2 is provided in which the activated carbon filter element 21 is provided, and the ceramic filter element 31 is provided in the third tube 3, the third tube 3 is provided with a filter port, a filter port. Used in insertion of the water to be filtered, the first tube 1 is provided with a drinking water port, and the drinking water port is used to flow out of the filtered water.

[0063] The drinking water port is provided with a nozzle.

Embodiment 2

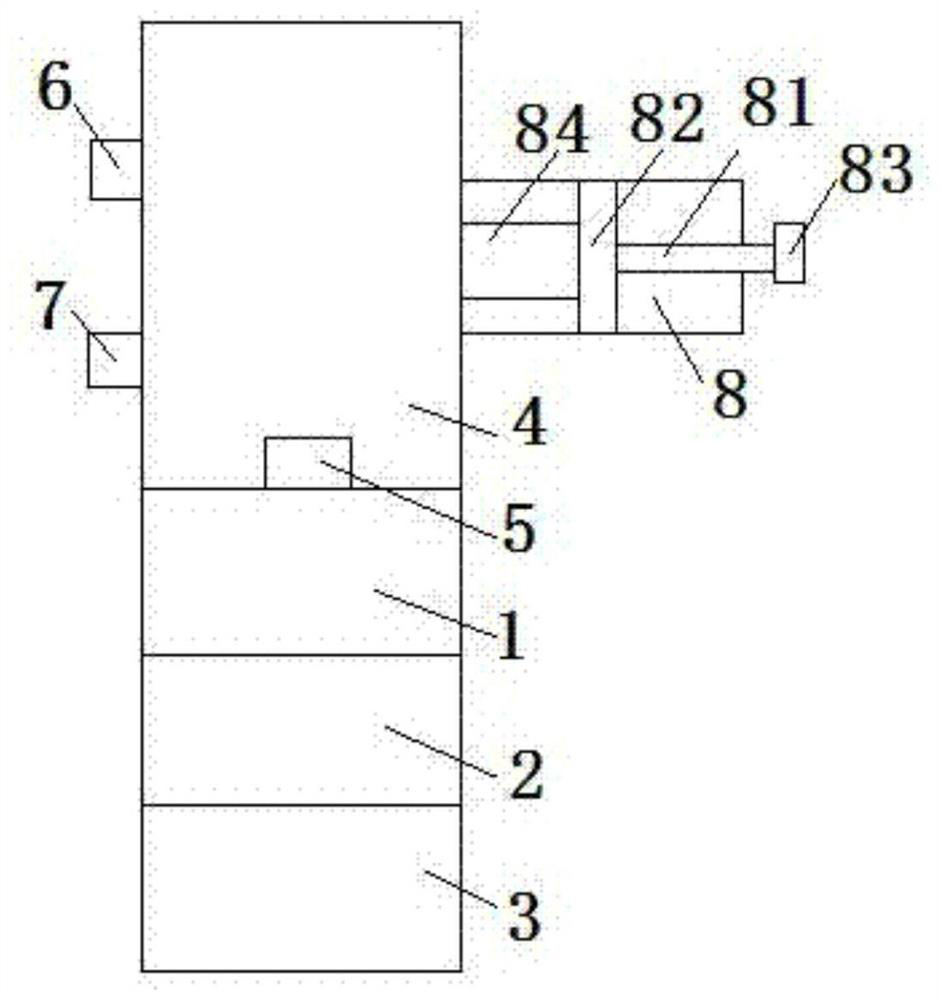

[0065] like figure 2 As shown, a water filter rod comprising a first tube 1, a second tube 2, and a third tube 3, a first tube 1, a second tube 2, and a third tube 3 sequentially connected by a threaded seal. The nano filter element 11 is provided in the first tube 1, and the second tube 2 is provided in which the activated carbon filter element 21 is provided, and the ceramic filter element 31 is provided in the third tube 3, the third tube 3 is provided with a filter port, a filter port. Used in insertion of the water to be filtered, the first tube 1 is provided with a drinking water port, and the drinking water port is used to flow out of the filtered water.

[0066] It also includes a pumping structure, the drawing structure includes a tubular sealing housing 4, and the housing 4 is connected to the drinking water port, and the bottom surface of the housing 4 and the drinking water port is provided with a first single-way valve that can pass through the drinking water port to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com