Superposed film photocatalyst for photochemical purifying gas, preparation method and application thereof

A photocatalyst and gas purification technology, which is applied in the field of air purification, can solve the problems such as the difficulty in the process of loading metal nanoparticles, and achieve the effects of convenient removal and renewal, reduced catalyst consumption, and strong adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

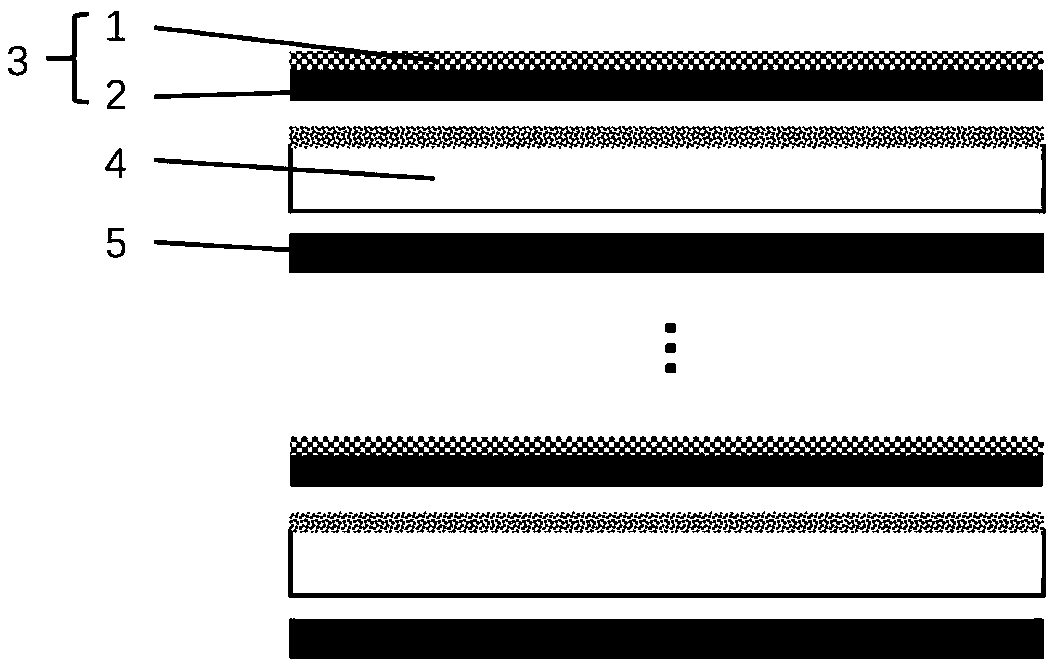

Method used

Image

Examples

Embodiment 1

[0028] Step 1, preparing a carrier film: using quartz glass (2.5cm x 2.5cm) as a substrate, uniformly deposit titanium dioxide formed by the reaction of tetraisopropyl titanate and water vapor on the quartz glass by atmospheric pressure chemical vapor deposition.

[0029] Step 2, carrier film firing: the carrier film on the quartz glass is raised to 500° C. at a rate of 5° C. / min, and maintained for 2 hours to prepare an anatase titanium dioxide film.

[0030] Step 3, load active components: add urea and chloroauric acid solution to deionized water, stir vigorously to obtain a mixed solution, the concentration of urea in the mixed solution is 0.062mol / L, and the concentration of chloroauric acid is 0.0005mol / L. The prepared anatase titanium dioxide film was put into the mixed solution, and the mixed solution was heated in a water bath, the temperature of the water bath was 80° C., and the time was 4 hours. Afterwards, the film was taken out, rinsed with deionized water, and th...

Embodiment 2

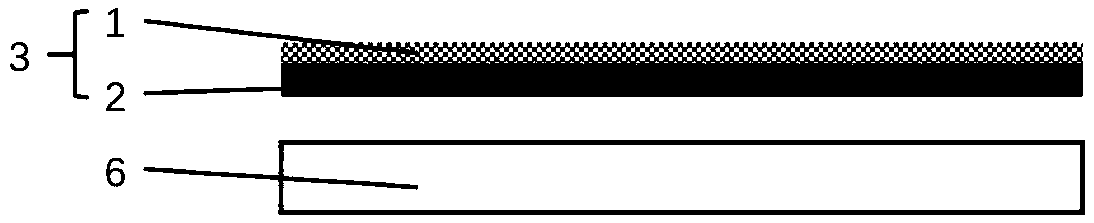

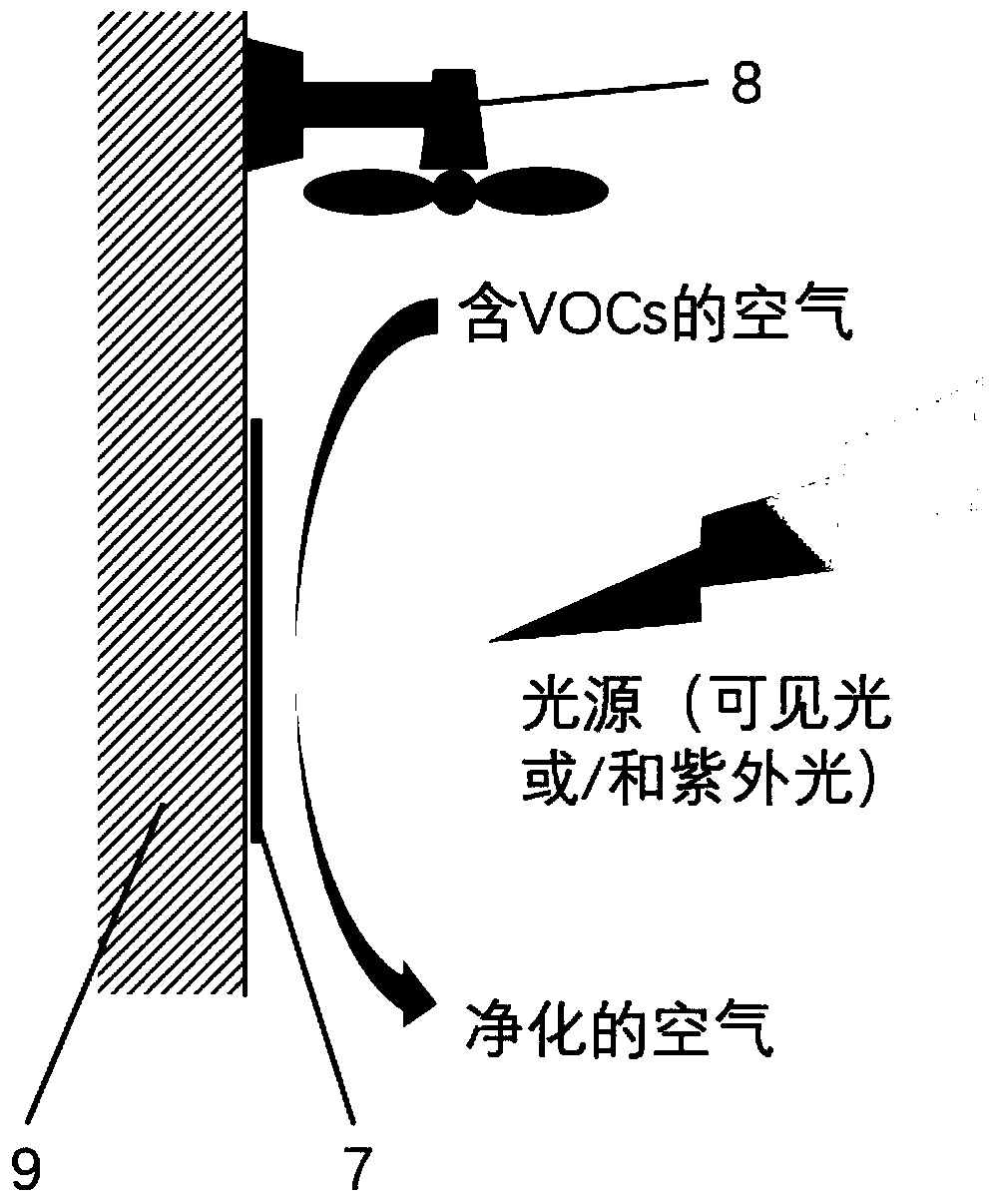

[0034] Taking polytetrafluoroethylene as the substrate, after carrying out nitrogen plasma treatment to it, adopt the method of step 1 of embodiment 1 to prepare the carrier film and the method of step 3 of embodiment 1 to load active components, and use oxygen plasma mode to treat the catalyst Thin film is activated to prepare Au / TiO 2 film. The actual content of the active component Au in the catalyst film is 0.01 μg / cm 2 , the mass percentage of the active component in the catalyst film is 0.1%. The other side of the substrate (without the catalyst) is coated with a non-adhesive adhesive to finally obtain a laminated film post-it note for photocatalytic gas purification. Paste it on the wall facing the light side of the bedroom to purify the indoor air with photocatalysis. In order to improve the air purification effect, you can turn on the fan, and when the humidity is low, start the air humidifier at the same time.

Embodiment 3

[0036]Using polyethylene as the substrate, using the method of preparing the carrier film in step 1 of Example 1 and the method of loading active components in step 3 of Example 1, the catalyst film is activated by argon plasma to prepare Au / TiO 2 Thin film, the actual content of active component Au in the catalyst film is 1g / cm 2 , the mass percentage of the active component in the catalyst thin film is 60%. Place it on the bathroom floor, turn on the light source, start the ventilation fan, and purify the indoor air with photocatalysis.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com